HoneyPlace / Beekeeping / Bee Hive Construction

0

Every beekeeper knows that wild bees live in natural hives: a hollow of a tree, under a roof, etc. But if you decide to engage in beekeeping, then you will need to make a lot of effort in order to equip bee housing. The construction of a bee hive begins with collecting useful information about the types of hives, the materials that are needed for construction, with approximate drawings.

Bee hive device

What types of hives are there?

Before you start building a bee hive, you need to understand what kind of design you want to get as a result. The fact is that today the following are considered the most practical types:

- The hive is horizontal. The beekeeper can expand it by setting up additional buildings.

- A vertical hive is a 2-3-tier structure, on each tier of which there are about 10 frames. You can expand the vertical structure by adding new tiers.

Also, hives are conventionally divided according to the types of frames, because it is the frames that are the main element of the entire structure. Depending on the width and height, they are square, narrow-high, or, conversely, low-wide.

What material is the best for making a beehive?

Hive material is a very important topic. The bees may simply not like their house, and the beekeeper will be forced to remodel it.

There are a huge number of different materials on the market today, but not all of them are suitable for the hive.

- Wood

Wood is a safe bet. It is better to purchase coniferous wood, this is pine, spruce, fir, etc. Before work, make sure that there is no rot or mold on the wood. Note that the tree has one drawback, it is high humidity inside the hive.

To equip the bee house, choose boards 5 mm larger than the design requires. They will decrease in size at the time of grinding. Boards need to be well planed so that there are no chips, roughness, protruding chips left on them.

- Plywood

Plywood is another great option. It is an environmentally friendly material that is durable. Beekeepers say that plywood surpasses even wood in terms of thermal insulation in terms of its characteristics.

To make a plywood hive, it is necessary to cover its outer walls with a layer of acrylic varnish, and put polystyrene foam inside the house. By the way, hives are also made from the latter, which are characterized by fragility and fragility.

You can make such a plywood hive only according to a drawing; it will become optimal for the comfortable life of insects.

- Polycarbonate

Polycarbonate is a hard plastic that cannot be affected by climatic conditions. Differs in stability, durability, does not suffer from rot, fungus, washes well.

- Other materials

Polyurethane foam can act as a heater, which does not rot and is not covered with fungus, it is not gnawed by mice. Its main disadvantage is flammability, and when insulating the hive with polyurethane foam, be sure to design a small ventilation system.

General requirements for bee houses

Whichever model you choose, the general requirements will be the same for any of them. But these requirements can be met in different ways.

General requirements for any type of construction:

- a universal design should be able to expand with an increase in the size of the bee colony;

- the hive must necessarily have high-quality ventilation, which provides fresh air and dryness from the inside;

- it is desirable that it retains heat well due to insulation or the materials from which it is made;

- the hive should be light enough to be easy to move;

- useful life - at least 15 years;

- the frames should not be adjacent to the walls; the optimal distance between them and the wall is at least 7-8 mm; frame thickness - 25 mm;

- for manufacturing, it is allowed to use boards made of soft wood: cedar, fir, spruce, pine, poplar, willow, linden;

- the wood must be free of knots;

- permissible moisture content of the tree - no more than 15%;

- the corners are connected with waterproof glue and nails;

- the outer part of the hive must be primed with linseed oil and covered with oil paint.

Did you know? Deep in the forests of the Himalayas, the largest honey bee in the world makes hallucinogenic honey from flowering rhododendrons. This honey is so precious that locals in China and Nepal risk their lives to harvest and sell them to wealthy and curious tourists.

Bee hive device

Maintenance of a multi-body hive

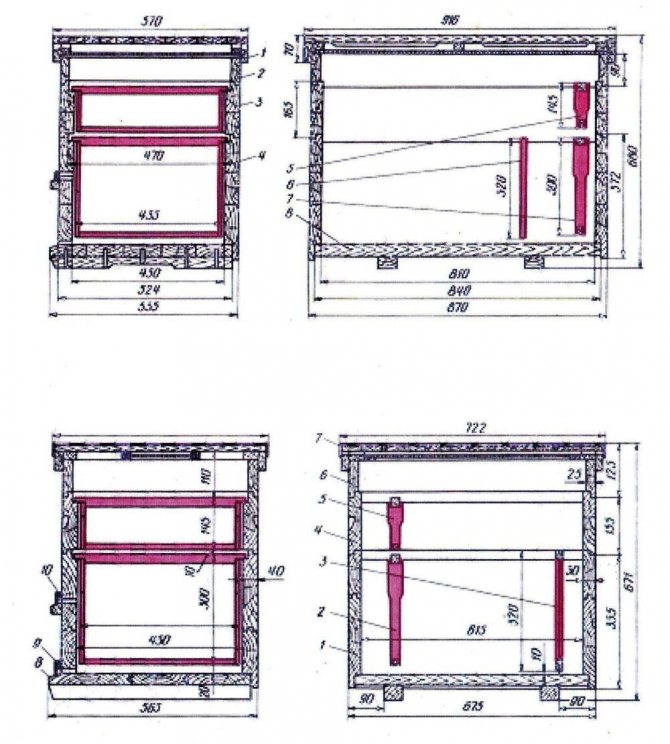

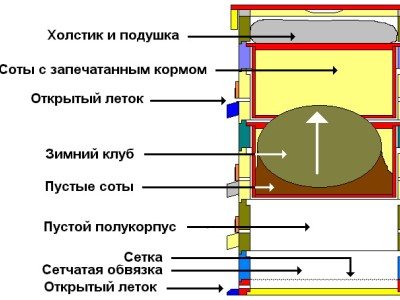

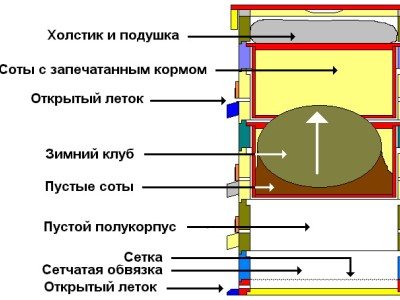

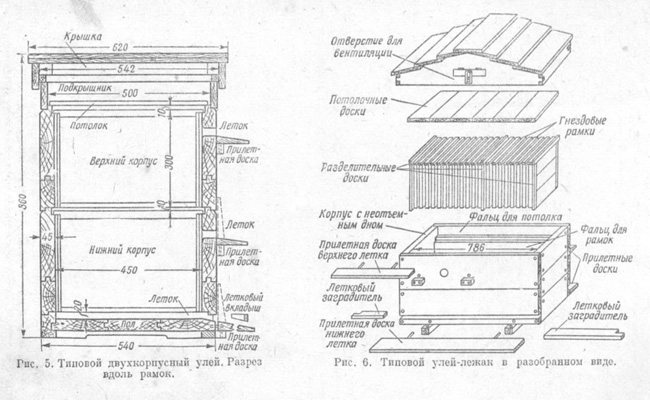

The hive consists of the following elements, fastened into a single structure:

- bottom (wood or mesh) and ceiling, front, rear and side walls;

- roof liner, insulation cushion, canvas;

- strips and overlays for them, folds;

- gable roof and lid rail;

- ventilation hole;

- entrance, landing board, nesting frame;

- waste tray or pallet;

- glass for observing bees and a board that covers the glass when needed.

Structural elements and their features

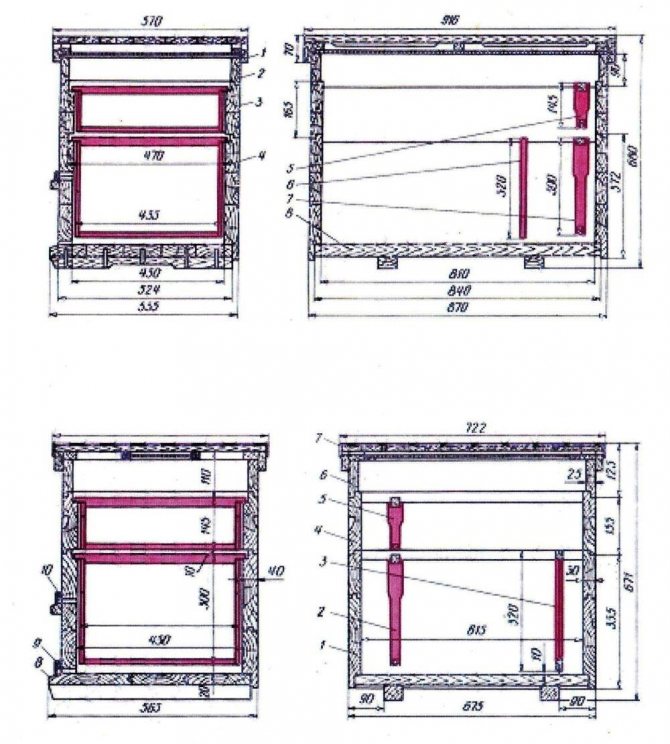

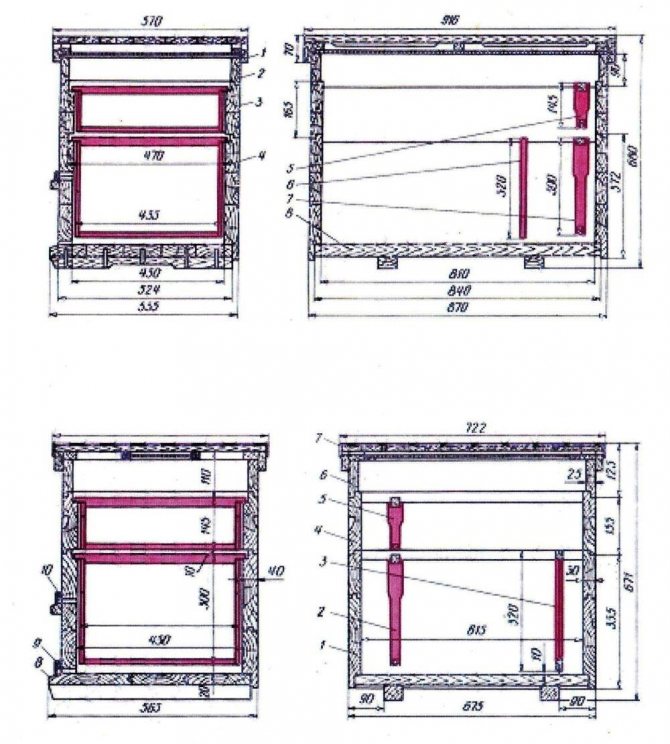

Most often, the hive has a modular structure - it consists of several detachable parts. This is convenient as it allows you to increase the volume as needed. Each of these parts is manufactured separately and the manufacturing accuracy must be high - all parts must be interchangeable.

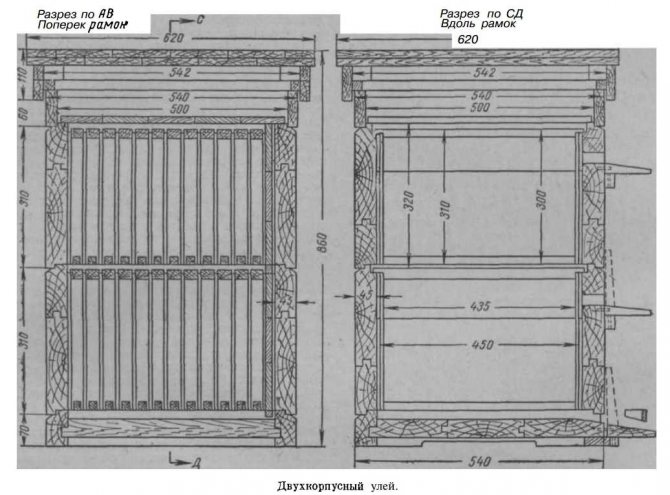

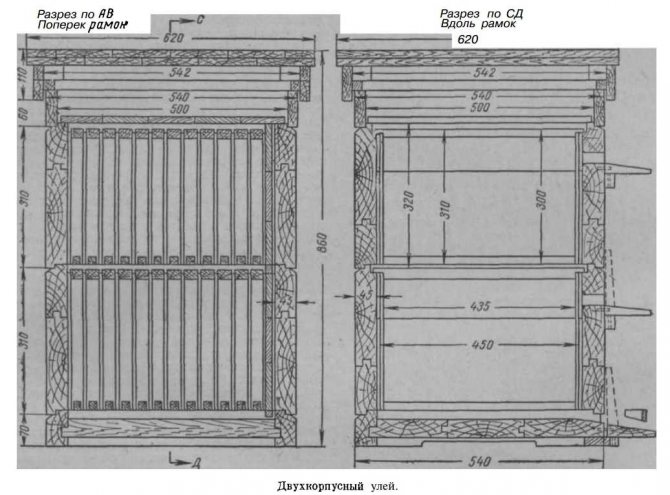

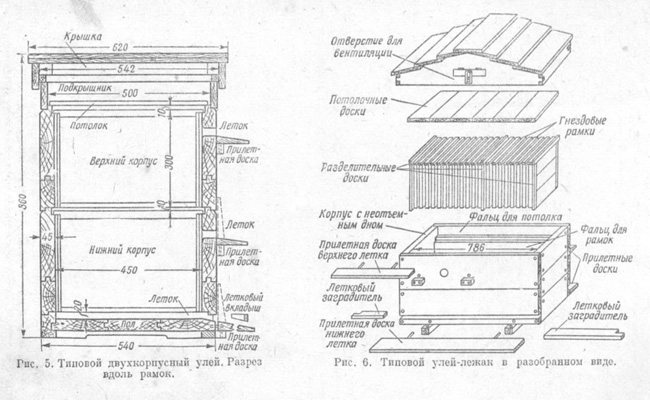

Dadanovsky hive of two buildings, placed one on top of the other

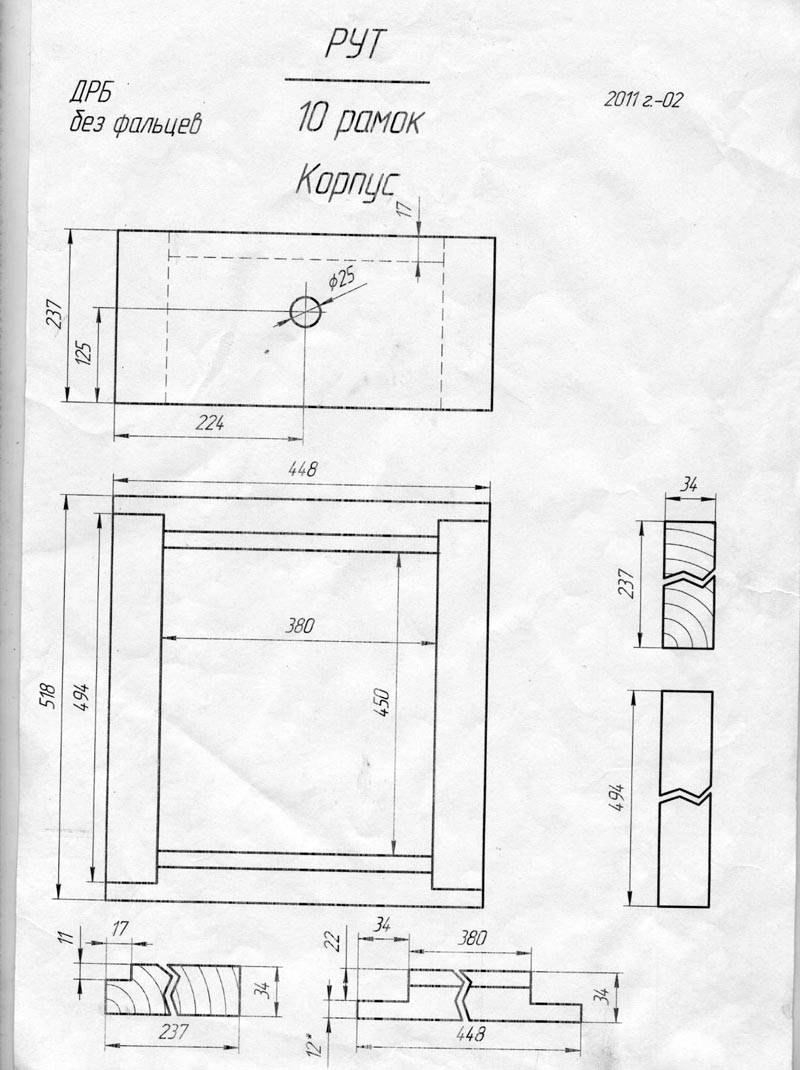

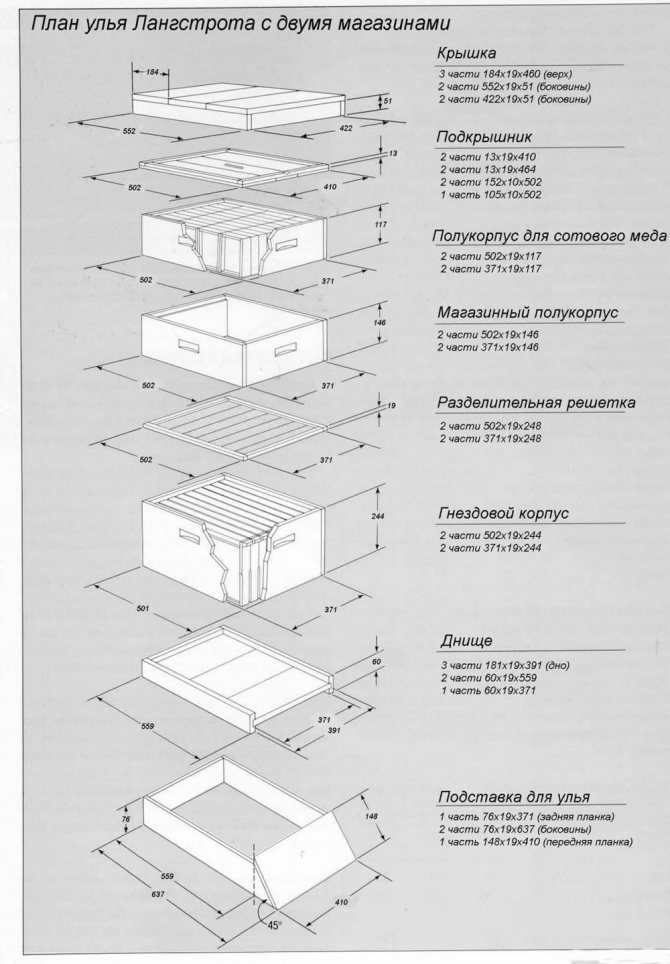

Housing

This is the central part of the hive, which usually contains the nest of bees. According to the number of hives, hives are single, double-hull or multi-hull (3 or more). Corps are mentored as the family grows.

Hive body for 12 frames

Roof

The roof of the hive can be single-pitched (tilted back) or gable. In the forehead case, it should be with overhangs - to protrude beyond the geometric dimensions of the hive and protect the walls from the effects of bad weather.

Roof structures for beehives

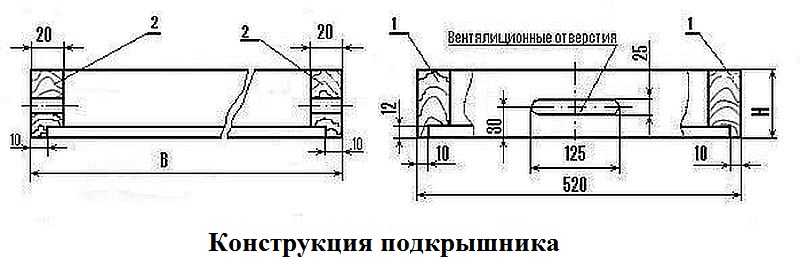

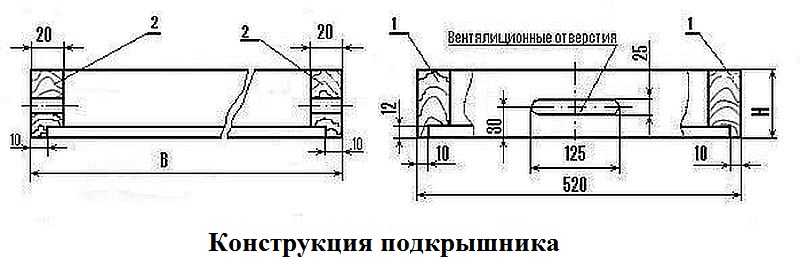

The roof consists of a roof plate - a flat body for placing insulation or feeders for feeding bees - and the actual roof planks nailed to the roof plate with nails or screwed on with self-tapping screws. The height of the pad depends on the thickness of the insulation, and this value depends on the region. Usually the height of the roof liner is 80-140 mm. Ventilation holes are often made in the under-roof to remove moist air from the hive.

Liner construction

When making a roof, the planks are stacked either in two layers with overlapping seams, or from thicker planks in one layer, but the seams are necessarily closed with thin strips. On top of the wooden roof of the hive, roofing iron, roofing felt or roofing felt can be laid.

When making a roof, pay attention to the fact that it "sits down" tightly, without cracks. To seal the joint around the perimeter of the body, you can fill a felt strip or nail a plinth outside the body to overlap the joint.

Bottom

The bottom of the hive can be nailed to the body (deaf) or can be pulled out or extended, that is, it can be detachable. The split bottom makes it easier to maintain the hives - it allows you to clean the bottom without disassembling the entire hive.Structurally, the bottom is:

- cold - from a single board;

- warm - from two layers with insulating backing.

Also, the bottom is double-sided - with protrusions of different heights on both sides, which allows you to adjust the internal volume. They knock it down tightly, without gaps, connect the boards in a quarter or in a groove with additional gluing of the joint with moisture-resistant wood glue. The cracks must be carefully repaired (with putty on wood), as wax crumbs are poured into them, and then a wax moth starts up. Therefore, from time to time they prefer to replace the bottom, making a new one.

https://youtu.be/A9eoeUfHZJg

How the hive works: dimensions and additional details

Sizing correctly is fundamental to creating the right hive. The beekeeper engaged in the construction must comply with the dimensions with great accuracy. We provide universal dimensions for all hives, which you can use as a basis:

- The distance between adjacent frames is 3.75 cm.

- Streets, subject to a honeycomb thickness of 25 cm - 1.25 cm.

- During the installation of the second body or additional magazine, a gap of 1 cm is made between the upper bars and the lower slats.

- The space between the front and back walls and the side strips should be 0.75 cm.

- The space between the bottom bar and the bottom is 2 cm.

The deviation from the dimensions is allowed within 0.1 cm. If there is a large discrepancy with the dimensions, you will have to adjust other structural elements, and the hive will no longer be composed of equivalent parts that you can replace in the future.

Classic version

To make a do-it-yourself bee hive from a traditional tree, you should acquire a set of carpentry tools, as well as boards with a moisture content that fluctuates between 15-16%.

The number of boards will be different for each, since the bodies can be made different. It is best to borrow the blueprint of the beehive from those who have previously created such structures and are actively using them.

Be sure to adhere to the basic parameters of the main elements - this will simplify operation.

In such a hive, the following elements must be present: plug-in boards (2 pcs.), Canvas or ceiling boards, burlap insulation.

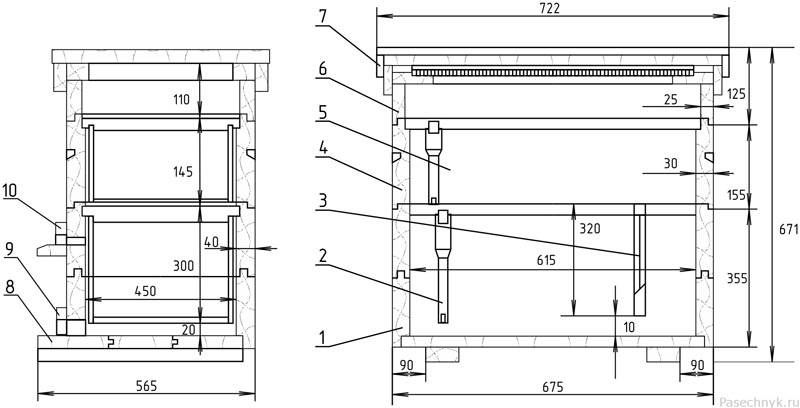

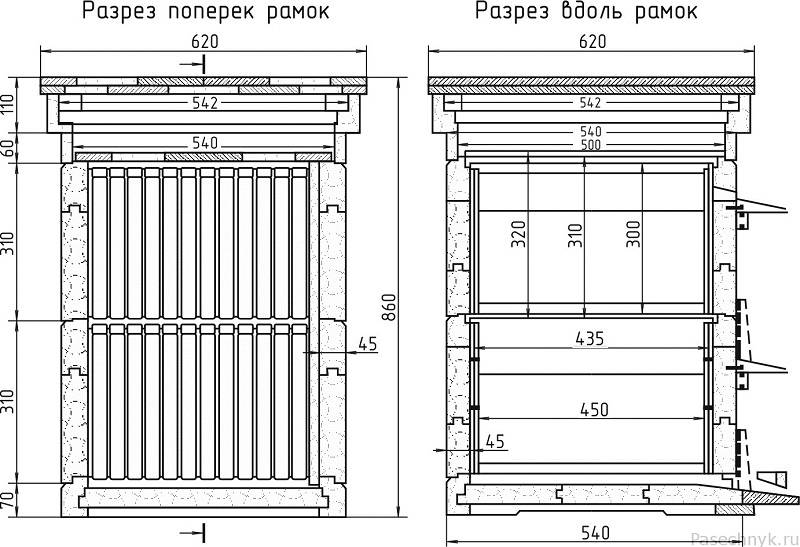

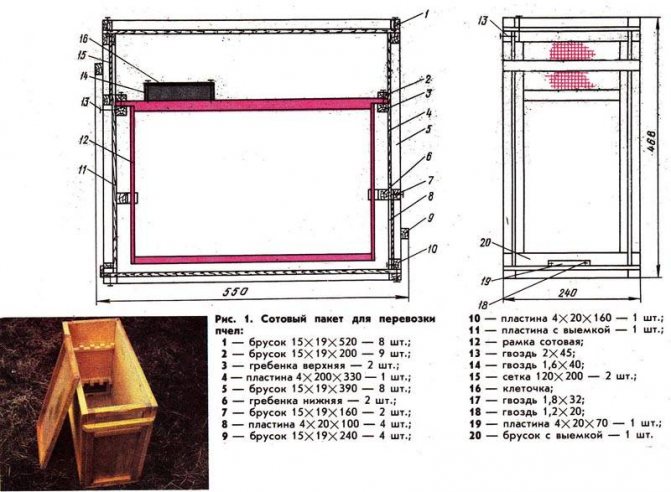

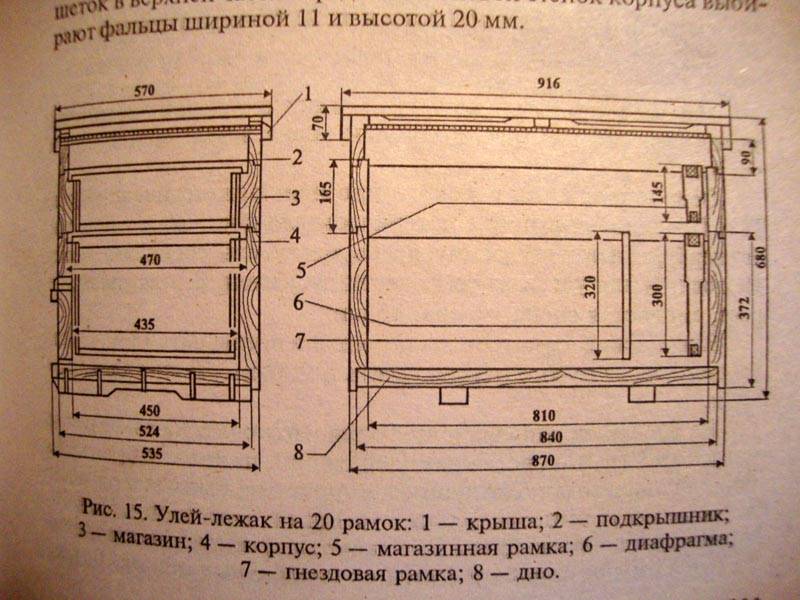

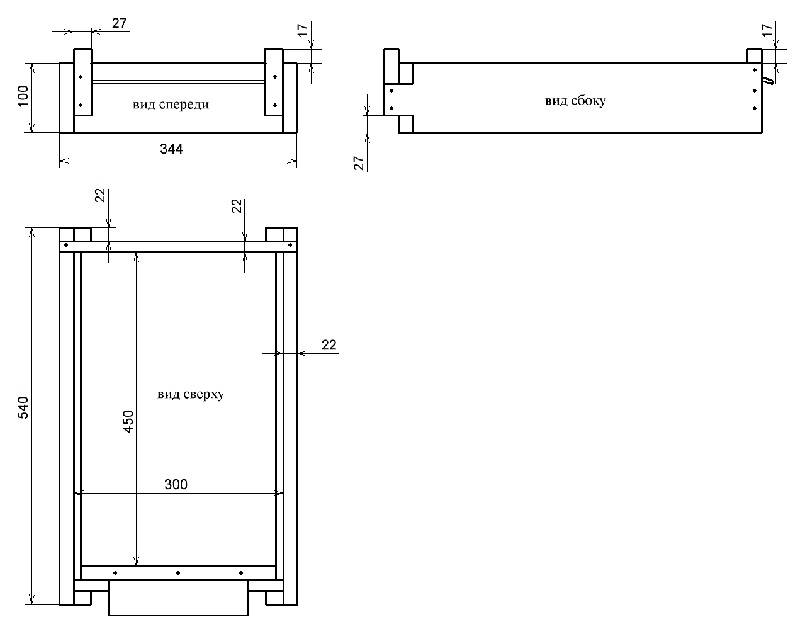

An approximate design and basic measurements are indicated in the following drawing of bee hives:

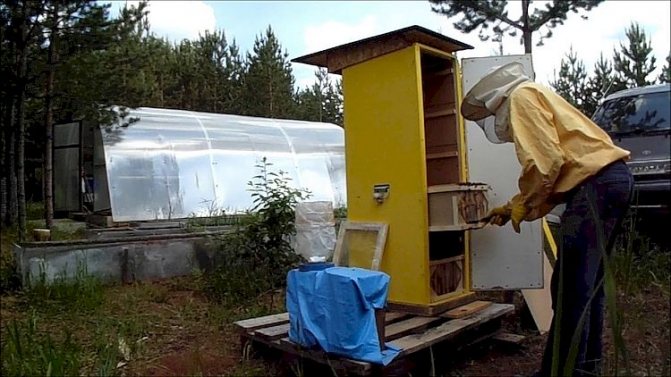

How to assemble a beehive: instructions

So, all the elements are ready, and the drawings are drawn. It's time to collect the hive. Begin the assembly by preparing the four walls, machined and cut according to the drawing. One of the front walls is connected to the two side walls, after which the last wall is fixed. After that, the side frames are attached to the side panels of the hive, then a wooden floor or mesh is attached. And on the front wall you need to cut a notch.

The structure is knocked together, set on the floor and a pillow with a canvas is reported, covering everything with a lid. A pillow and a lap are needed to control the temperature. The bottom of the hive is best made of galvanized material, it should be removable, which will facilitate the transportation of the hives. And for the frames, choose a good, but not resinous, wood.

Do not forget about the feeder, which is most often made from a nomadic net. In winter, at low temperatures, the hives are heated with electrical appliances with a power not exceeding 10 watts.

Summing up, it should be said that making the beehives on their own requires great attention and strict adherence to the drawing. It must be remembered that the hive should be comfortable for insects in all respects: not hot and not cold, without chemical odors emitted by some synthetic materials, with a normal ventilation system.

Manufacturing nuances

It is not necessary to completely copy the finished drawing of the hive. It is possible to combine successful devices of different designs, for example, use a high bottom according to German technology.One and the same solution is radically changed by small nuances - whether or not to make holes for tap holes in the hulls, to use a blind or mesh bottom, etc.

The most popular material for making beehives is undoubtedly wood. It is important to consider its moisture content before building the evidence. According to GOST, it should not exceed 15%. In the case of a high moisture content, the structure will inevitably lead, the dimensions of the board will change.