A well-known entrepreneur and beekeeper, publisher of The American Bee Journal, founder of a firm for the production of beekeeping equipment Charles Dadant in 1974 published the book “A Short Course in Beekeeping”. It contained a description of a new beehive invented by him, which later became known as the "Dadan-Blatt hive." In his design, the inventor embodied the best developments of his time, combining them with simplicity of manufacture and ease of use.

Studying the life of bees, Dadant calculated that a young queen is capable of laying up to 3,000 eggs in one day, and a healthy bee colony can fill 1,500 prepared cells during this time. As a result, it turned out that for normal life it would be necessary to install 11 wide Queenby frames placed in one building. In this case, the bees will surely have enough room to accommodate the collected honey.

The design turned out to be successful and became popular not only in the United States, but throughout Europe. However, the harsher European climate made it much more difficult to organize the wintering of bees. Therefore, the Swiss Blatt suggested using the Langstroth frames and increasing their number to 12. The last inventor-designer who brought this design to its modern form was the outstanding European beekeeper Eduard Bertrand.

Despite its high efficiency, the Dadanovsky hive has practically no industrial production, but it is very popular among amateur beekeepers. The simplicity of manufacture allows even novice beekeepers to get hold of such hives, without resorting to buying factory models.

Hive Dadan - construction

Nowadays, the Dadanovsky hive is represented by several types of structures. The main differences are volume, material and insulation.

The dimensions of the structure are a strategic issue. It is important to understand what is needed in specific conditions.

- 10 frame. The classic Dadant scheme.

- 12 frame. The square section allows you to position the frames in different ways (with a warm or cold skid).

- 14 and 16 frame. It's harder to work alone. The increased number of frames creates a greater load on the structure.

Material

High-quality material will last longer, will not warp or rot. Materials with a strong odor must not be used.

- Boards. Wood without knots and rot is suitable. An insufficiently dried tree will dry out over time, cracks will appear.

- Plywood and fiberboard. Cheaper, easier to handle, but less durable.

- Polyurethane foam. Lightweight, warm, durable, soundproof.

- Expanded polystyrene. Lightweight, warm, soundproof and less reliable.

Insulation

Depending on the temperature conditions, one of the types is chosen:

- Double-walled. The walls are double, insulation (sawdust, moss, straw, polystyrene) is laid in the gap between the walls. Keeps you warm in unpredictable spring weather. Recommended in the middle and northern latitudes of Russia.

- Single-wall. An easy option not designed for low temperatures.

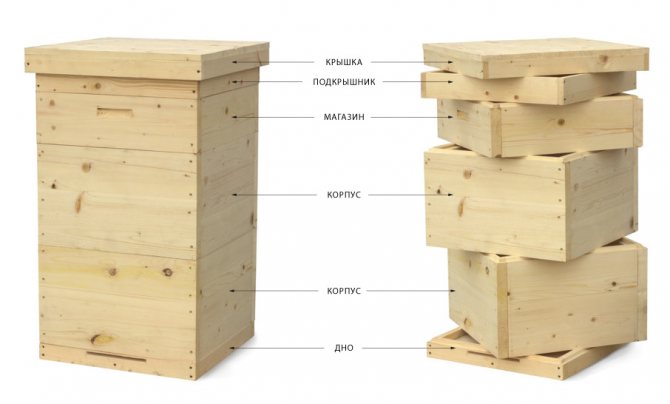

What does it consist of

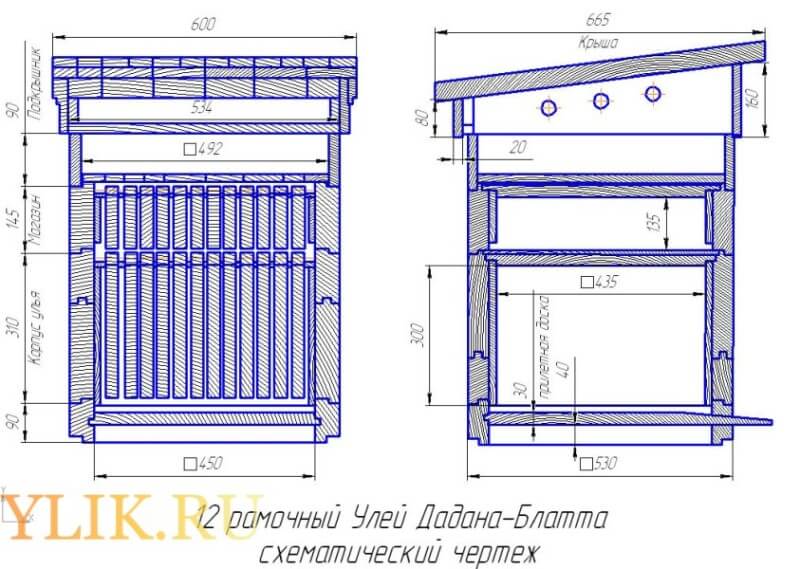

Regardless of its size and other features, the Dadan-Blatt hive consists of the following elements:

- Housing. Must match the drawing exactly, not skew. All other parts of the structure are attached to it. The letok is located in the hive building.

- Bottom. Usually removable. The fixed bottom is more airtight and tougher, but makes it more difficult to work with bees.

- Extension (store). Installed during the period of active honey collection. By special techniques, the uterus is not allowed to lay eggs in the store. In principle, 2 extensions stacked on top of each other can serve as a second body.

- Roof cover. Needed for ventilation and insulation of the hive.

- Roof. Most susceptible to weathering. The roof is painted in 2-3 layers or sheathed with tin. Roofs are pitched, gable and flat.

- Minor construction details (tap holes, folds).

Why is it worth stopping a choice at the Dadanov hive?

First of all, we had to abandon the classical version, as it was not voluminous enough, but the system lives on. We have a modified Dadan hive, which is in use today and consists of one or two buildings with several stores.

There is enough space for the bee family here when the period of the main flow begins. Such a bee house has enough space for a queen to lay eggs, worker bees, and there is still room to process nectar into honey and store additional food.

July will end and the bees will take the lower part of the hive to continue collecting honey at a slower pace.

In August - the time to prepare the hive for the winter period. By November, the hive is ready for wintering.

After the spring check of the bees, the hive is cleaned, additional feed is made, the nest is expanded if there are 10, not 12 frames in it. This usually happens in the last days of April. As soon as the whole building is occupied by the family, very quickly, so as not to violate the temperature regime, an additional one is placed under them, with a fiefdom and dry land.

The bees will work hard, build honeycombs in it over the summer, and then go to the fresh ones for the winter.

For the period of maximum intake of nectar, a store is delivered. It is here, on top of the nest, that the bees will begin to lay food. If necessary, additional ones are placed between the nest and the first magazine.

Such a Dadanov hive of many buildings for a family of bees becomes an ideal home.

> Video: Making a beehive (Dadan)

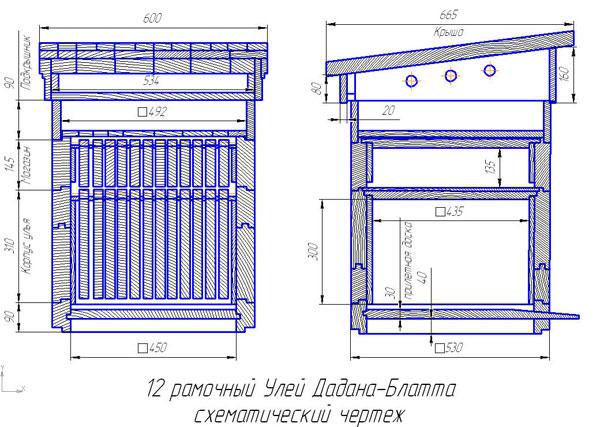

How to make a twelve-frame Dadan hive with your own hands

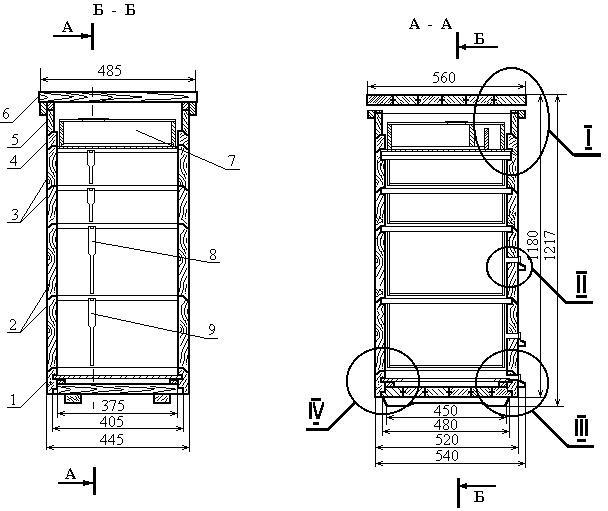

The dimensions and drawings of the twelve Dadan frame hives are given for the single-wall type, since the second walls are built on top of the inner ones, and do not matter.

Preparation for work

With some skill, making a Dadan hive yourself is not difficult. There are several important points.

- Storage and processing of wood in a dry place. Only dried wood is used.

- Study the drawings in advance and imagine the order of work.

- Prepare tools and materials.

A job well done will last a long time. The lifespan of a manufactured hive depends on the material.

Operating procedure

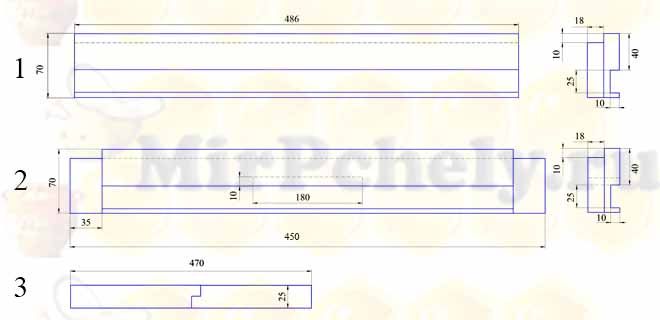

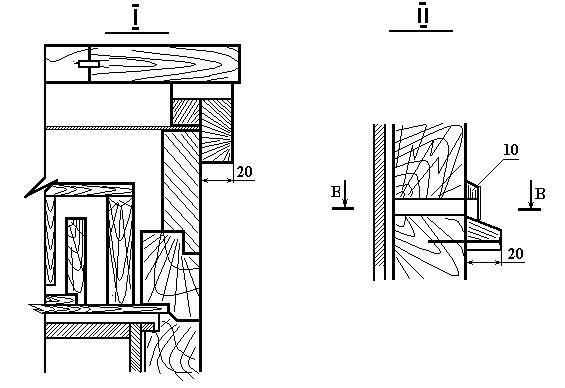

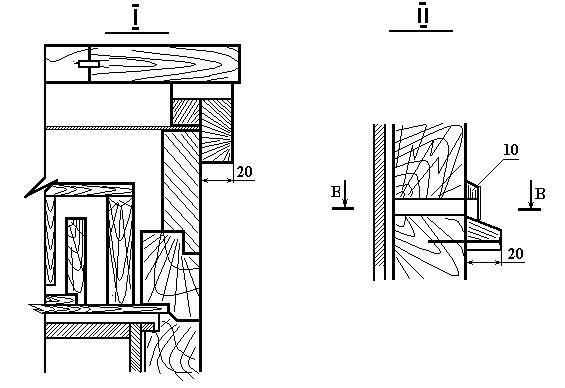

- Blanks are cut from a 35 mm board according to the drawing. The joints are prepared, the folds are selected. The workpieces are ground.

- When assembling wide boards, they are opposed to narrow ones (if the front lower board is wide, the side lower boards are taken narrow).

- The joints are glued. PVA or wood (casein) glue is used. It is important that the glue does not have a strong odor and is not toxic to bees.

- The ends of the connections are additionally reinforced with pins or self-tapping screws. Allow the glue to dry before reassembling.

- The upper notch is drilled out, the lower one is cut along the edge of the body.

In the process of making the bottom, extension and roof, it makes sense to periodically try them on in order to notice mistakes immediately.

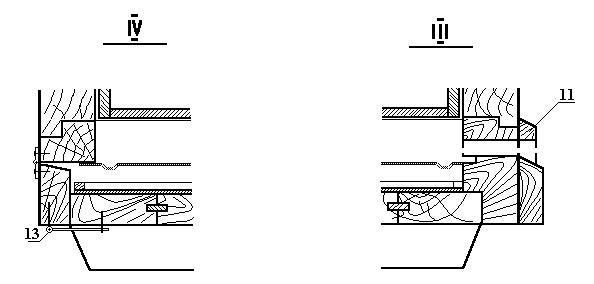

- The removable bottom is made wider and is assembled from the boards in a quarter (or in another way with good tightness). Three strips are packed in such a way as to enter the fold at the bottom of the case. The front side remains without a strip for ventilation. Boards can be taken thicker than 4 cm, this will make the bottom heavier, but make it stronger.

- The superstructure (store) is assembled similarly to the body. A rebate is selected along the upper edge of the superstructure.

- The roof is put on the body or store.Over time, they change shape a little, so you need to make the roof landing not too tight. Ventilation holes are arranged on the sides or in the front. To transport the bees, you need to close the holes with a fine mesh.

A find for bee lovers

The Dadanov hives did not receive wide industrial distribution. But amateur beekeepers appreciated the small single-hive hive, the main advantage of which is the use of special store extensions for storing honey stocks, light and convenient, half the size of the hive.

There is another difference as well. It lies in the approach to working with dadans and American multihull hives.

You can work with hives of this type alone, because here the principle is to periodically remove only honey frames, and not to change whole bodies, as in the last Rut version. For owners of small home apiaries, the choice in favor of convenience is obvious.

Beekeepers have long known that bees lay food supplies on the sides and, most importantly, on top of the nest. Some breeds prefer to have a large top layer in stock and only then feel safe.

How to make a ten-frame Dadant hive with your own hands

The scheme for making a 10 frame Dadan hive is the same as for a 12 frame hive. You can use 35 mm boards (the load on the structure is now less). It takes up little space and is easier to work with.

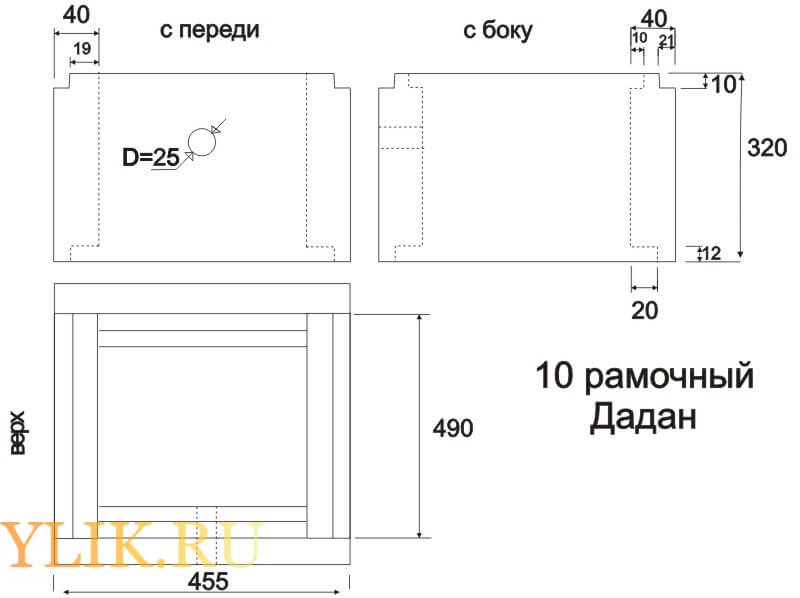

The size of the ten-frame hive

In comparison with 12 frame, only the length of the side walls and the corresponding dimensions of the roof and bottom change.

| Length mm | Width mm | Height mm | |

| Inner size | |||

| Housing | 450 | 380 | 310 |

| Score | 450 | 380 | 155 |

| Roof | 450 | 380 | 70 |

| External dimension (with a board thickness of 35 mm) | |||

| Housing | 520 | 450 | 320 |

| Score | 520 | 450 | 165 |

| Bottom | 520 | 450 | 70 |

| Roof | 520 | 450 | 80 |

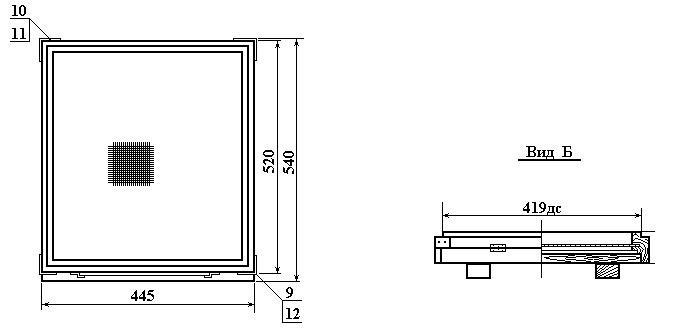

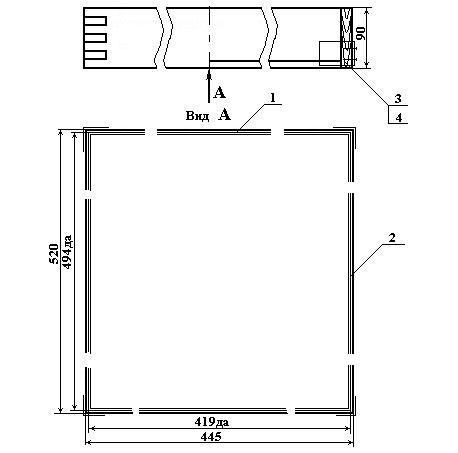

Dadant Ten-Frame Hive Blueprint

The ten-frame hive differs from the twelve-frame hive only in width.

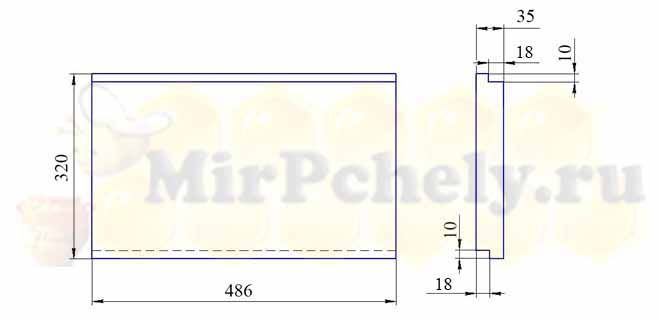

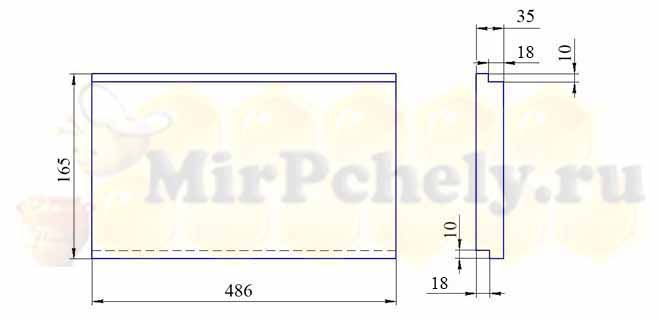

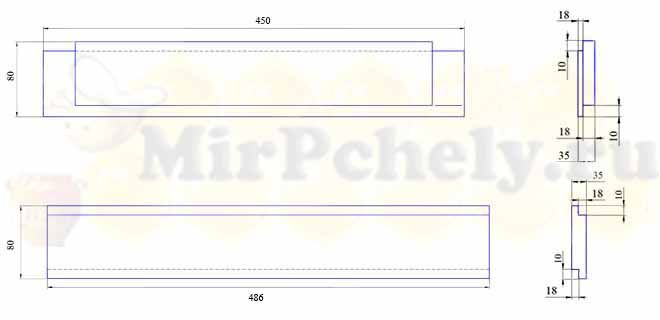

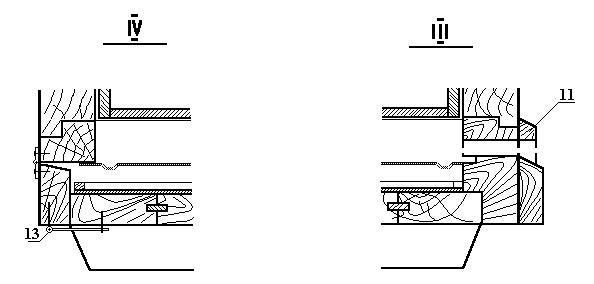

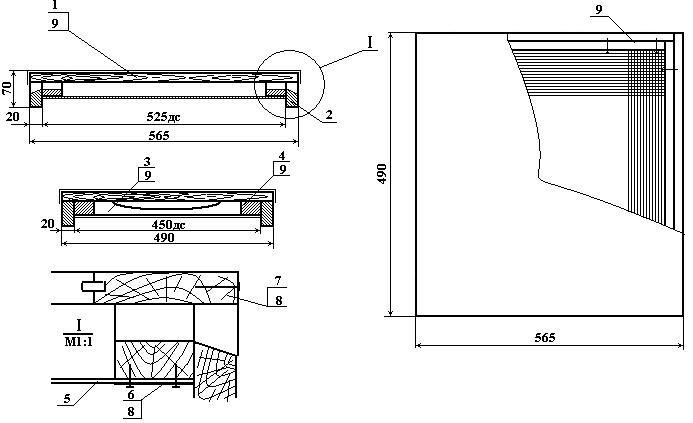

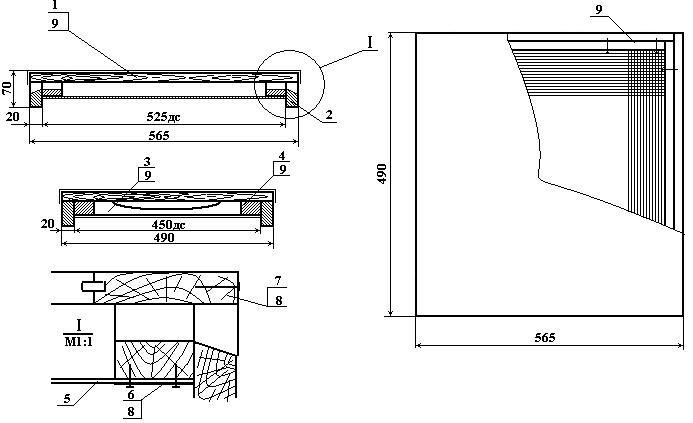

Hull drawing

The side wall is similar to the 12 frame one. And the front and back walls are smaller. An upper tap hole must be drilled in the front wall.

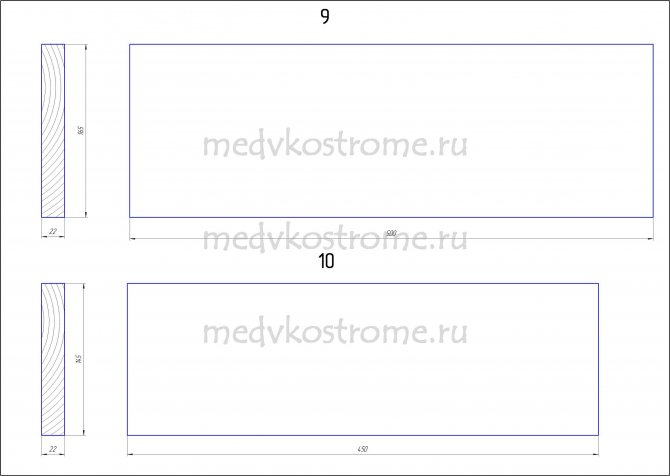

Side wall of the Dadan case for 10 frames

The front wall of the Dadan case for 10 frames

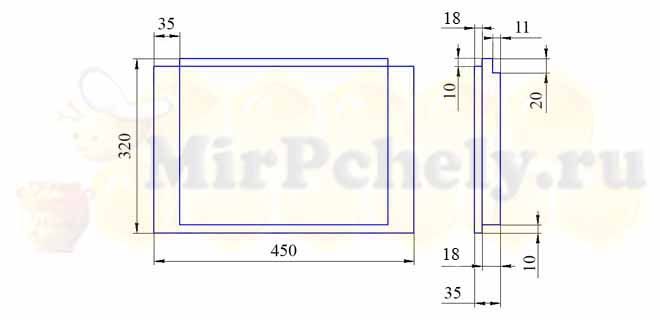

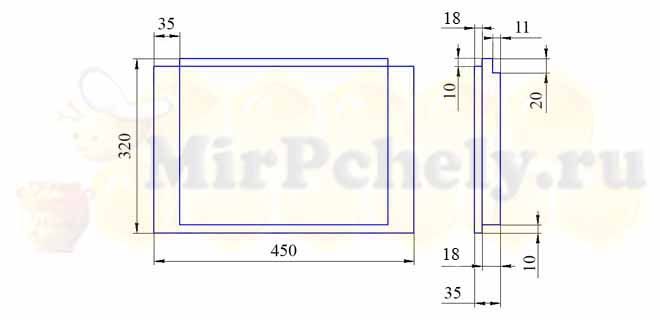

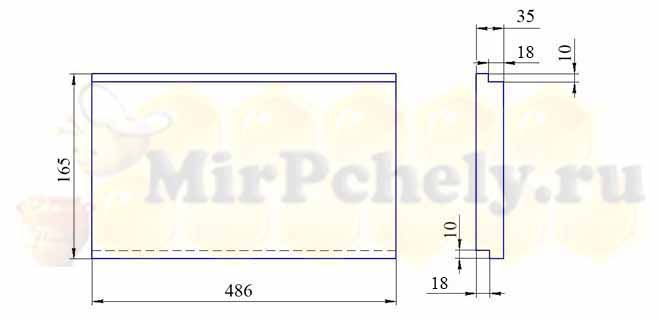

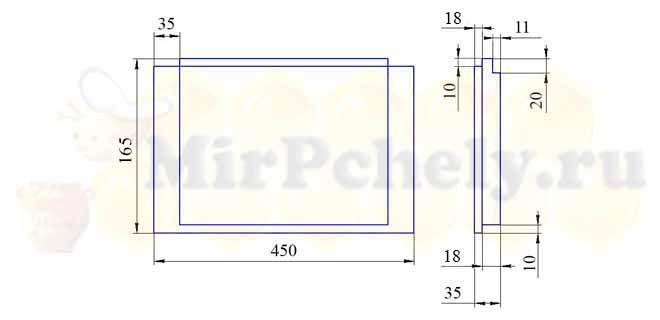

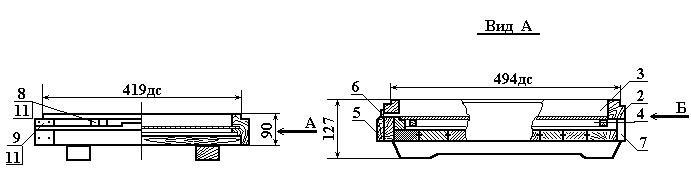

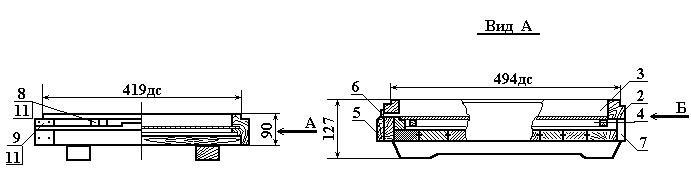

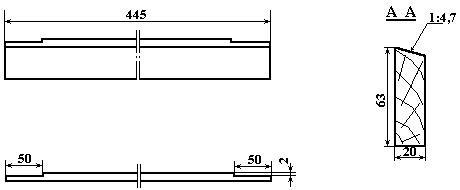

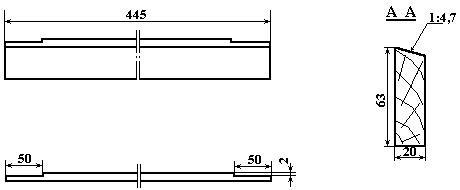

Shop drawing

As well as for the body, only the dimensions of the front and rear walls change relative to the 12 frame structure.

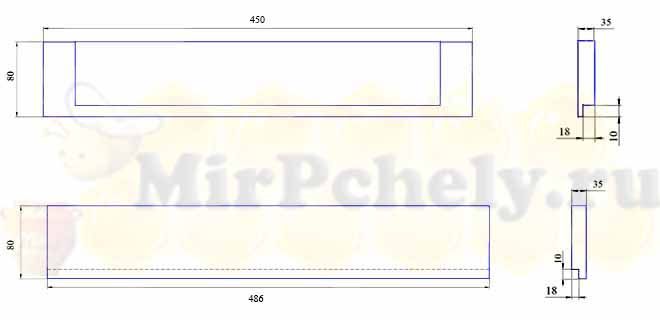

Side wall of Dadan store for 10 frames

The front wall of the Dadan store for 10 frames

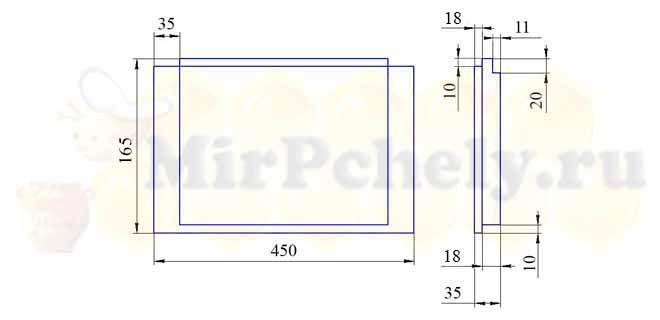

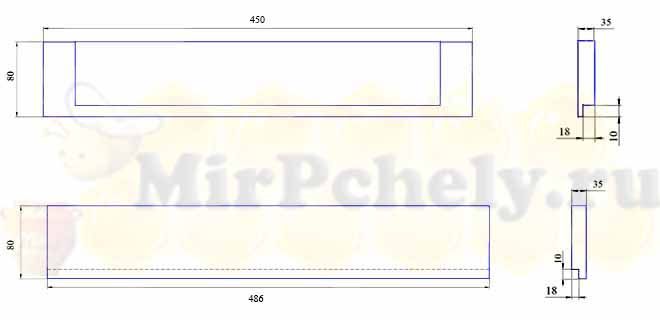

Liner drawing

If you need a sub-roof, it is assembled similarly to the body and the store, but has its own dimensions.

Roof cover Dadan for 10 frames

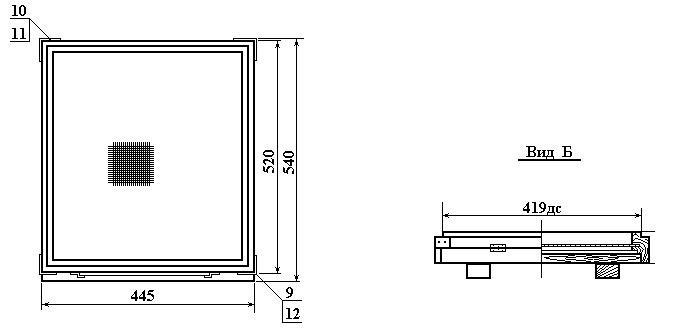

Roof drawing

After assembling the frame, you need to fix a 540mm * 470mm plywood sheet from above or tie it with a 20mm board, provided that the roof is horizontal. On the inside, insulate, and on the outside, cover with a sheet of iron, tar paper, linoleum or other material that does not allow moisture to pass through.

Dadan roof for 10 frames

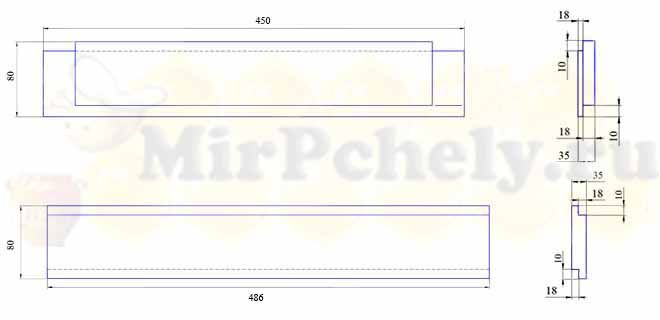

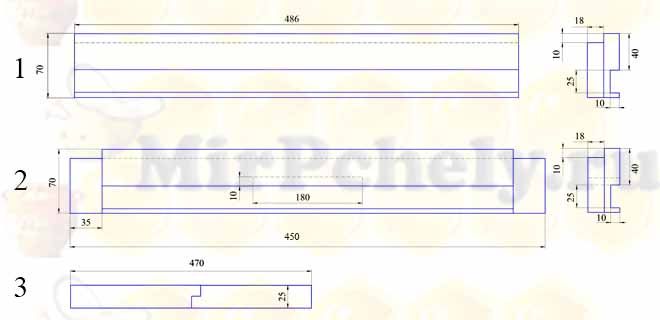

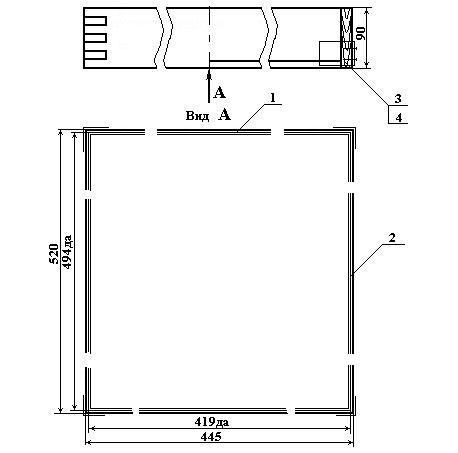

Bottom drawing

When making the bottom, we prepare two side walls (1), the back one (2 without a tap hole) and the front one (2) in which you need to make a tap hole 10 mm in advance for the length of the tab you have prepared. You also need to prepare in advance the bottom (3) from a 25mm board, measuring 470mm * 400mm. Having connected the 2 side walls with the back, we insert the bottom, only then we close the front wall. You can fill a board under the entrance.

Dadan bottom for 10 frames

Blueprints

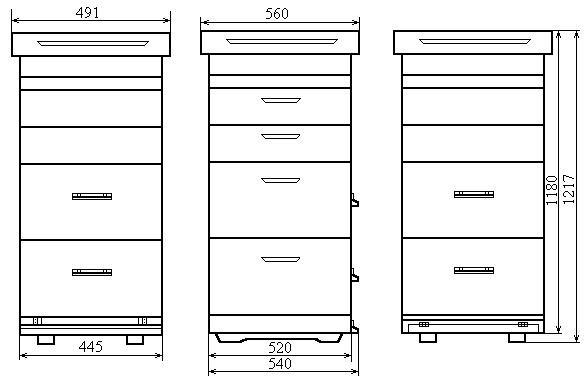

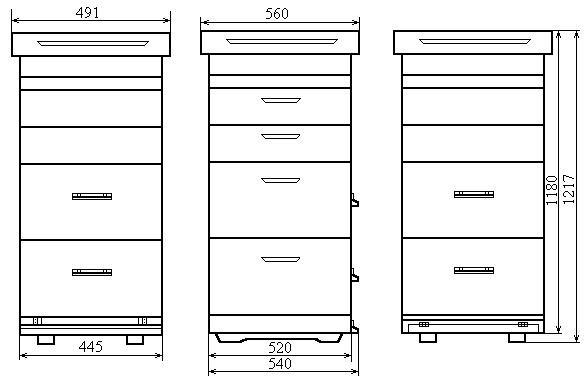

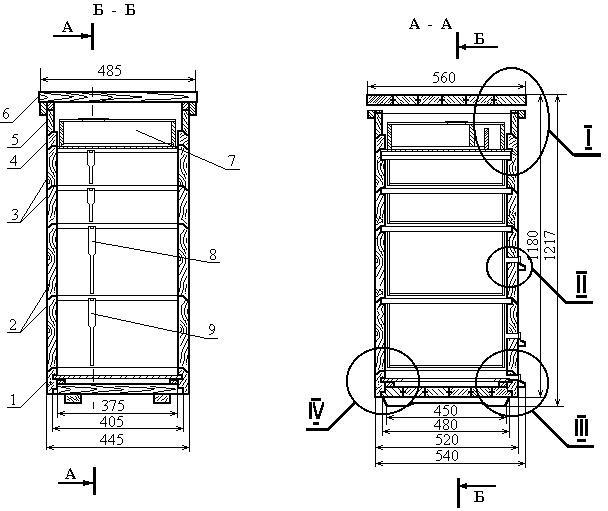

Before you build a house for a bee family yourself, you must carefully study the drawings of the Dadan hive using the example of 10 frames:

10-Tite House Dadan

10-yard hive with shops

10-lane hive with 2 shops

10-lane hive with 3 shops

Bottom dimensions with pull-out mesh and tray

Bottom dimensions with pull-out net and tray 2

Arrival board

Roof liner

Cap

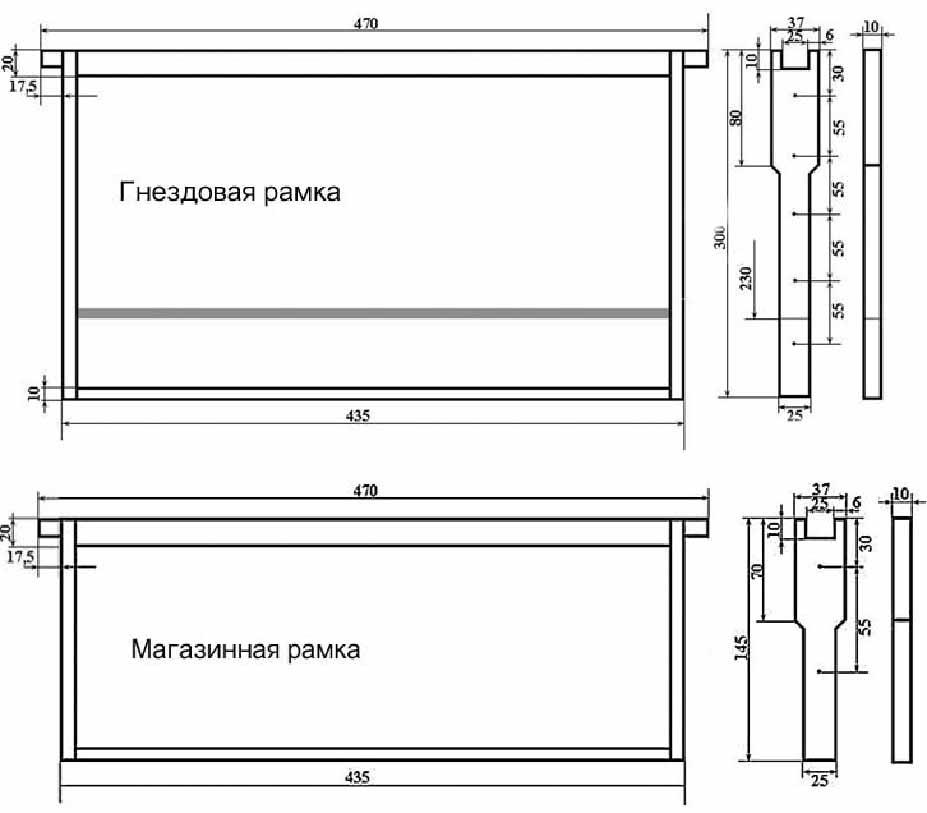

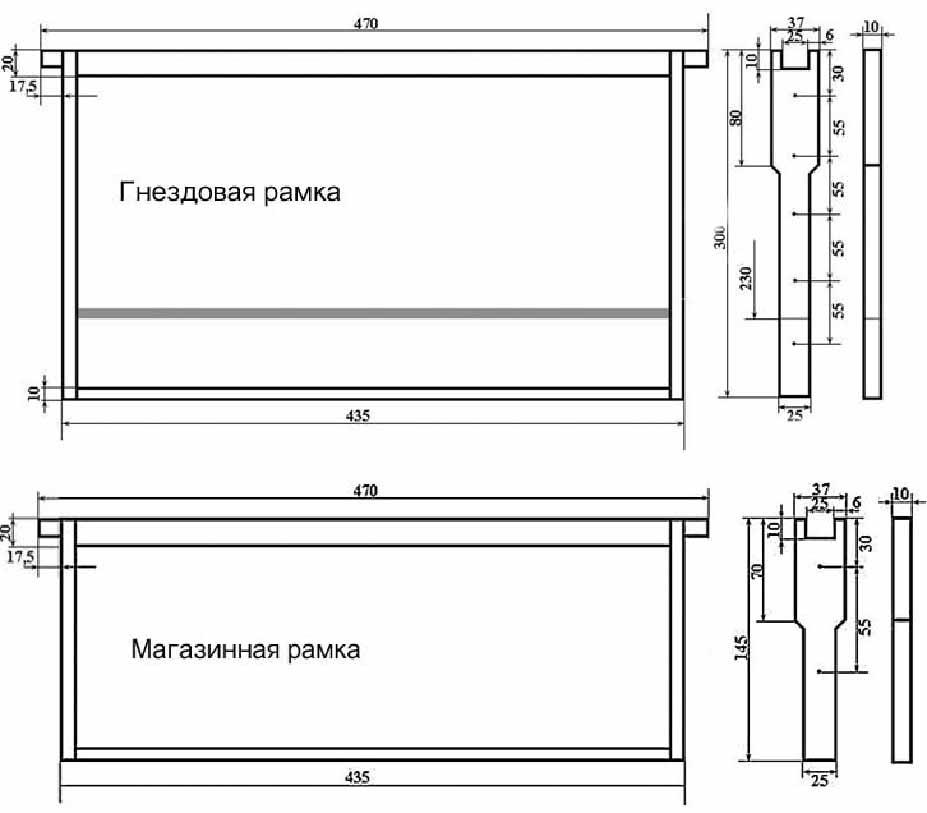

Nest and magazine frame

Nest and magazine frame 2

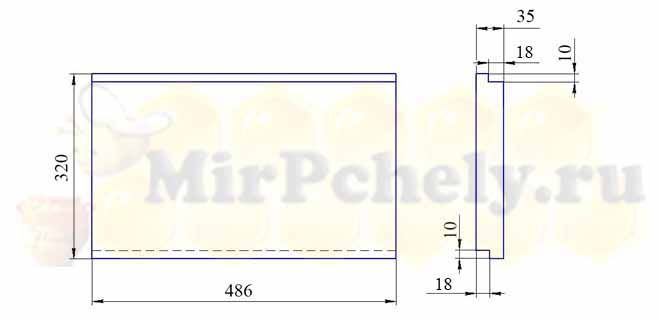

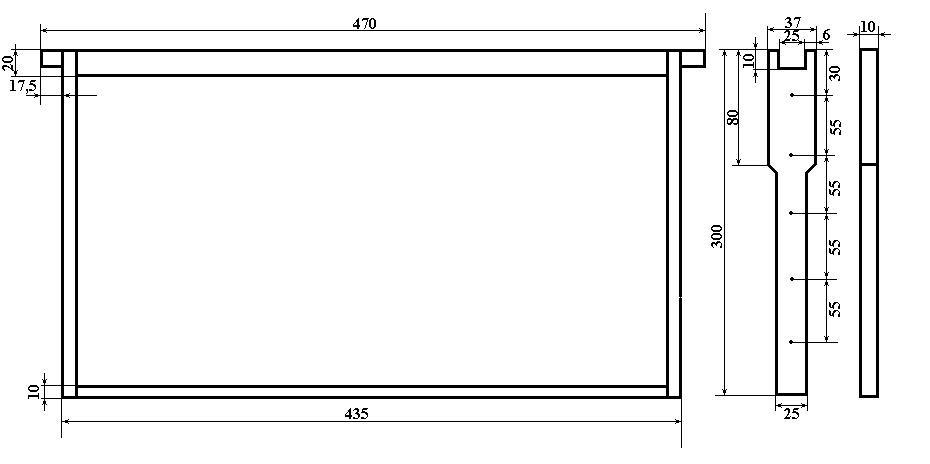

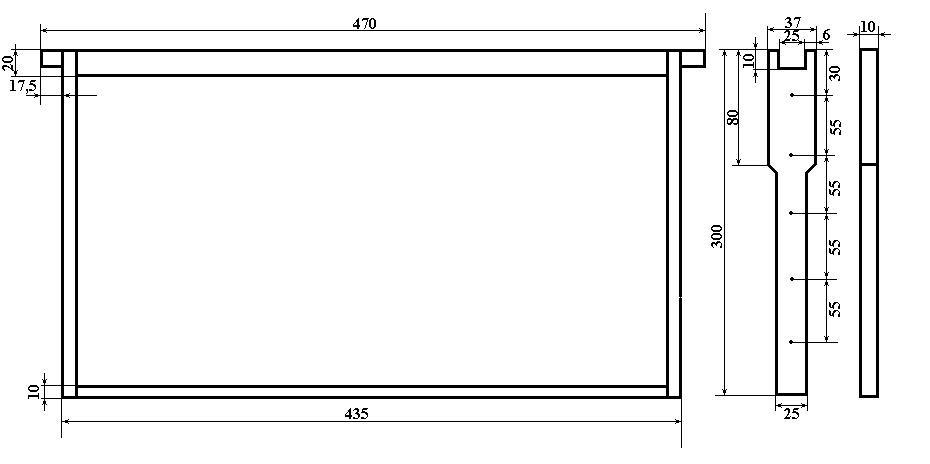

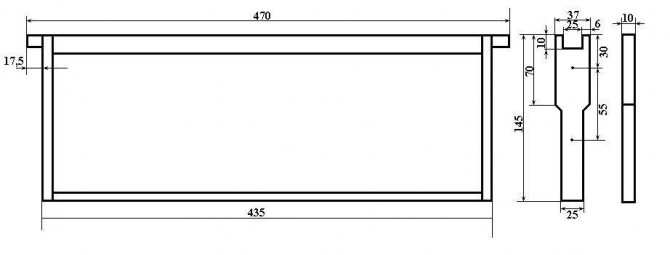

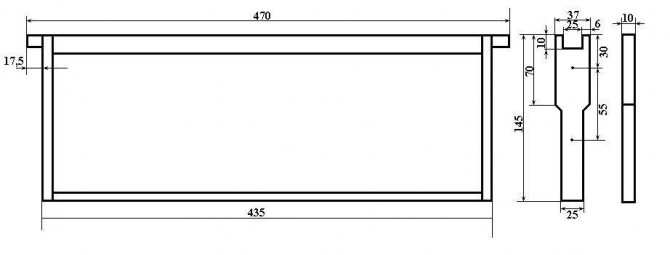

Dadant frame

The size of the Dadan frames differs from the standard ones, with the same length they are higher. They are made from soft deciduous trees, such as linden.

- The body frame Dadan has dimensions of 435x300 mm.

- Store 435x145 mm.The height, of course, depends on the height of the extension itself.

Dadan frame drawing

The Dadan-Blatt hive is reliable for mid-latitudes. The standard 12 frame design is easy to manufacture. Using high-quality material and observing the technology, you can count on a long service life of the hive.

Where to get a drawing of a beehive in 12 frames

Drawings of Dadan's hives are found in sufficient quantities in the vastness of the worldwide network.

When starting to make a structure with your own hands, you must use a drawing. Namely, having a drawing in front of your eyes, you will thoroughly know the dimensions of the hive and can be guided by them.

Much more often, beekeepers give preference to hives not from 10, but 12 frames. You can make one with your own hands using various materials: wood, metal, expanded polystyrene. And so that all the details are connected accurately and neatly, it is very important to observe the dimensions that the drawing contained. If cracks appear, they will have to be putty and then sanded. Coloring is also important.

The 10-frame design is used when you want to reduce the load on the case. In addition, such a case is compact and easier to work with. The design of the hive is practically the same as for the 12 frames. But a drawing is required. How else will you find out the features and dimensions of such a design.

Such a hive, which you build with your own hands, using the drawings, observing exactly all the recommendations, will be better for you than any other, regardless of whether you have provided 10 or 12 frames in it.

Some design features

Charles Dadant was born in 1817. In the early 60s, he and his family immigrated to America. The most important thing for him was beekeeping. All his life, he has worked to optimize this entertaining, rewarding, but so hard work. According to his calculations, about 3,000 eggs are laid by a young uterus during the day.

House for bees

Later, he calculated that in order for bees to completely fill an ordinary honeycomb with honey throughout the day, it must have 1,600 cells. He concluded that the beehive must fit 12 or fewer frames... Therefore, the total number of all cells in the hive will be 10.5 thousand. This was the reason for invention of the optimal design of the hive... Most interesting is the fact that he used some of the ideas of other inventors, not at all embarrassed about it.

Later, Dadant's ideas were significantly improved by Blatt, who was the first to understand the imperfection of the hive. He made some design changes that were useful for full wintering of insects on the European continent... Thus, until today, mankind uses the Dadan-Blatt hives.

In addition, Dadan's work is continued by his descendants. The DADANT company, which produces beehives, is well known all over the world. Their implementation is quite successful, since many beekeepers want to purchase branded bee houses. True, the price is a little tight for our pocket, although the quality of the products does not cause the slightest doubt.

Benefits

The main advantage of the Dadanov hive is the correct organization of the space inside. Thanks to this, it is possible to place even two families in one house, with a special separation board installed inside. Another distinctive feature of the 12 frame hive is easy access to the collected honey thanks to the removable bottom.

Describing the full range of benefits, it is worth highlighting:

- Internal dimensions are suitable for a large bee colony;

- Lightweight honey collection process;

- Removing and replacing frames is quite easy and simple;

- Reduces the likelihood of swarming bees when kept with 12 frames;

- The operation process is long. For 25 years it has not lost its main characteristics;

- Due to its functionality and simplicity, it can be easily used even by beginners in beekeeping;

- Two families can hibernate when installing a special partition;

- Due to its widespread use among beekeepers, repairing a part or individual elements is quite simple. This is due to the fact that in almost any beekeeping store you can buy elements of the Dadanov house;

- If necessary, you can form a multi-hive hive by setting up an additional store for collecting honey or an additional hive;

- In areas where there is a reduced level of honey yield, this type is often used.

Requirements for materials

In order for the hive to last as long as possible, you need to consider the following:

- use only high-quality wood;

- precisely fit all parts to each other;

- reliably protect the roof from moisture ingress.

For the manufacture of hives, it is recommended to use wood with a moisture content of no more than 15%.

To reduce the cost of the house, the structure can be made of plywood 5 mm thick, which is nailed to a wooden frame, and sawdust is poured inside.

Features of the Dadanov hive

The Dadan hive is widespread in beekeeping. However, the design has a number of features:

- During the main honey harvest, the house becomes cramped, since the bees fill all free cells with nectar, thereby limiting the laying of eggs by the queen. It is important not to miss this moment and substitute the store in a timely manner. Otherwise, the colony will become weaker, the number of bees will decrease, which will lead to a decrease in honey yield.

- If the hive becomes crowded due to the large number of bees, the probability of the colony entering a swarming state is high.

- To avoid swarming, you need to monitor the bees and put store extensions in a timely manner.

In the Dadanov hives, the honeycombs of the body frames are occupied not only with nectar, but also with bee bread with brood. Therefore, it is more convenient for pumping out to take stores, the frames of which are completely filled with honey, and in order to exclude the transition of the uterus to the extension, a dividing grid is used.

Characteristics

The hive is distinguished by its simple and reliable design. According to Dadan, the vertical arrangement of the colony creates better conditions for the bees and reduces the likelihood of swarming. In addition, a strong family may well be located in one building.

Dadanovsky hive consists of the following parts:

- Square case with dimensions 450x450x320 mm. All walls are of the same thickness.

- The case is designed to accommodate 12 frames with an external dimension of 435x300 mm. The frames themselves are made of strips and are held in the body by means of "shoulders" in the quarters of the body. A free space of 8 mm must be provided between the frame and the body for the movement of the bees.

- Cap. Protects the hive from above by putting it on the body. The front of the lid has ventilation holes that are covered with a metal mesh.

- Bottom. It is removable, which provides a quick change of part if necessary, for example, in the spring.

- A canvas is covered over the frames, and a pillow is laid on top of it.

In addition to the described design, one or two magazines can be installed on the main body. They are half the height of the body. The dimensions of the shop frames are 430x160 mm.

The lower edge of the magazine extension frame must be flush with the lower edge of the magazine itself.

The popularity of the Dadanov hive is due to the fact that both beginners and experienced beekeepers use this system. Such hives are easy to handle, move, which is especially important when wandering.

Dadant hive weight with honey

For beekeepers who take out hives to the fields for the summer season, Dadan is not entirely convenient - by the fall, filled with honey, it has a significant mass. Although the design itself without frames and a store weighs on average about 24 kg.

The honey-filled hive has a significant mass

Each empty frame has a mass of 0.5 kg, i.e. 12 frames add another 6 kg. If it will be easy to deliver 30 kg to a flower meadow, then it is already difficult to take it back, judging by the calculations below:

- with a good season, about 5 kg of honey accumulates on one frame;

- then the total mass of the frames will be 5 * 12 = 60 kg;

- adding the weight of the hive (60 + 30), get 90 kg.

This is just one structure that needs something else to be brought back to the farm. But, on the other hand, the frame system allows you to pump honey directly at the place of collection and take it out in parts.

To slightly reduce the weight of the hive, you can use lighter natural material instead of boards. High-quality plywood with proper use will last a long time.

The only drawback is that it retains heat poorly. But it can be easily eliminated - you just need to combine plywood with polystyrene, which is lined with the inner walls of the hive. Then the bees will be able to calmly winter in such a house.

Each beekeeper will decide on his own how convenient the described structures are, the presence of a detachable bottom and the possibility of using the store. For an experiment, you can start with one house in order to evaluate its advantages and disadvantages. It will not be difficult to make a Dadan 12 frame hive in size with your own hands.

Important! The modified hive is superior in efficiency to the classical options, simplifying the work of the beekeeper and creating the most comfortable conditions for the bee colony.