How to make a stall (barn, shed) for cows?

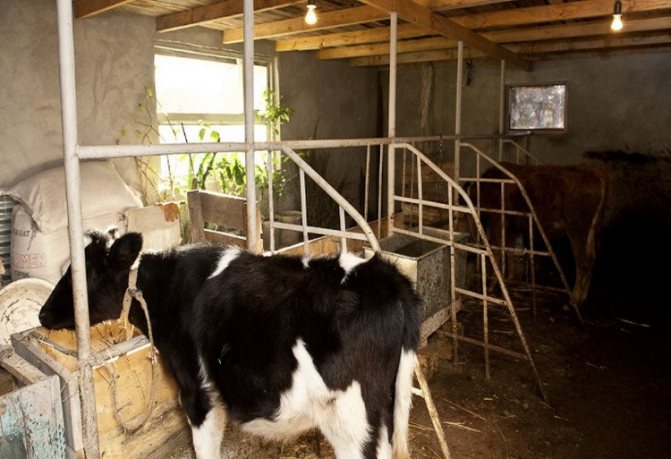

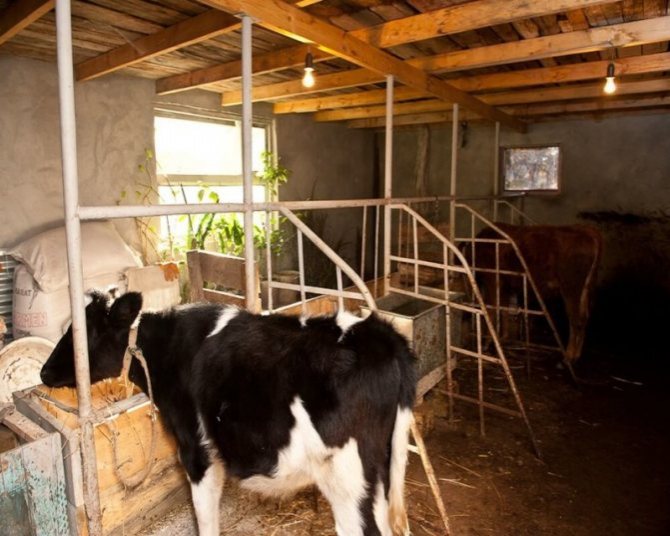

The barn of such a breeder is, of course, insulated, with supply and exhaust ventilation. The cow stall is always dry as the manure does not fall onto the floor, but into the groove behind the stall. From the groove, it is pushed to the hatch at the bottom of the wall, and from there it is thrown out.

To clean the grooves, take an iron shovel with a rectangular tip. If it is dirty not only in the groove, but also in other parts of the barn, it is convenient to use a simple pitchfork with a wooden attachment instead of a broom. Such a scraper can be cut from a block of any size with a beveled bottom surface and several holes on the other side. The forks are inserted into these holes - and the scraper is ready. After work, it is removed away so that it does not accidentally fall into the stove.

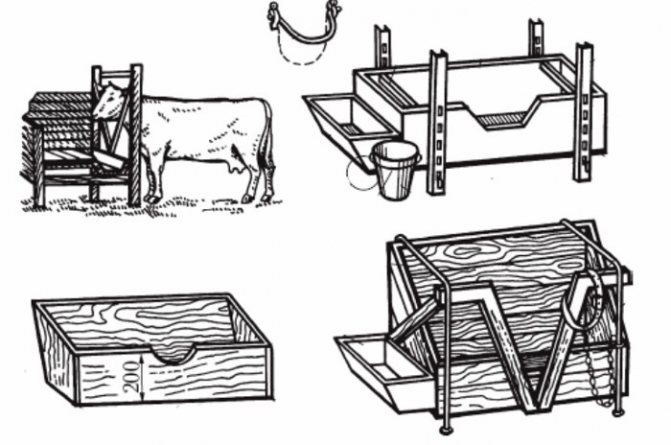

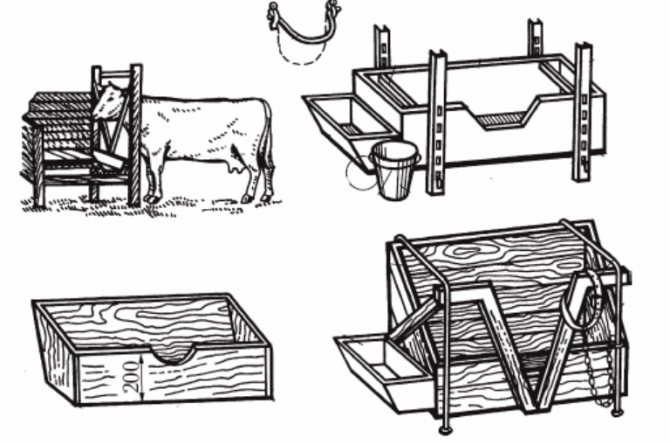

Not the last thing on a home farm is the installation of feeders for cows, you can even arrange a barn for 50 heads. Usually, a deep oblong box (trough) is nailed in front of the stall, and hay is put in it. Loose or dry grain dressing is carried out in a bucket. For hay, it is better to attach a lattice manger above this feeder, and then what falls from the manger falls into the box below.

But there is a feeder, from our point of view, is more convenient. It is attached to the side wall. It will hold a large armful of hay. The cow will eat it right above the feeder, it is easy to rake the leftovers in the trough, and from it to scoop out through the side that rises up. In the same trough, you can pour bran, mixed feed, put chopped beets, pumpkin, potatoes.

An experienced breeder also has a comfortable bench for milking a cow. How often does it happen? The hostess sits on an ordinary bench, and puts the milk box on the floor. Then he carries it home and there, going to strain the milk, puts it on a stool or table. It is not hygienic, and sometimes you have to hold the milk tray with your feet. Take just such a bench. It has a recess for the milk tray, which is held in place with a wire. The front solid support is equipped with a forward-protruding plate on which the milk tray is placed. You can sit on the bench sideways, or you can sit on horseback - and so, and so it is convenient.

In which cage should a calf be housed in the first weeks of its life, or even to do without it? No, a calf can feel bad without a cage - it goes through, because the door to the barn is sometimes opened wide. Nowadays, there are many designs of calf cages, mostly metal. We think we will not be mistaken if we say that it is best to put a wooden cage in the barn of a personal farm and that it would be nice to have the one called the Evers cage. This simple design has served for many decades, and to this day it serves baby calves in some places.

The walls of this cage are made of planks (made of plywood), dense and protect animals from drafts. It is easy to disassemble and clean, wash, disinfect and reassemble. True, they say that wooden parts are more difficult to disinfect than metal ones, but wooden ones are warmer, and material for them is easier to find. In one of the end walls there is a window for drinking a calf. Under the bottom there is a tray for draining the slurry into a bucket. The walls and floor are removable and easy to clean.On especially frosty days, the cage is covered with a shield, and then both top and bottom are covered with armfuls of hay, leaving a small hole in the window for ventilation. Of course, in this case, more litter is laid in the cage itself.

Arrangement of the feeder

In livestock farming, there are several farm options to meet the needs of different animals. If we are talking about cattle - cows, then feeders for them must be designed and installed in accordance with certain requirements and conditions. Any container will not work; cow feeders must be separated by feed type. So for wet and dry food, they must be different.

A feeder for dry feed - grass and hay, needs to be made hinged, rectangular. To prevent the cows from digging and spilling feed, the front wall of the trough can be made with a lattice so that the animal can get the required amount of feed through the bars.

To give wet food, buckets or special plastic containers are used, which can be purchased in finished form in specialized stores. To save space, you can also make them mounted or fixed in the corner. But the wet food trough should be easy to remove for washing.

In general, all feeders need to be washed and dried periodically to ensure the hygiene of the animals, so it is worth making them removable.

In livestock farming, there are several farm options to meet the needs of different animals. If we are talking about cattle - cows, then feeders for them must be designed and installed in accordance with certain requirements and conditions. Any container will not work; cow feeders must be separated by feed type. So for wet and dry food, they must be different.

A feeder for dry feed - grass and hay, needs to be made hinged, rectangular. To prevent the cows from digging and spilling feed, the front wall of the trough can be made with a lattice so that the animal can get the required amount of feed through the bars.

DIY cattle feeder: step by step instructions

There are ventilation slots all over the ridge of the barn. There are windows and ventilation ducts in the wall fences.

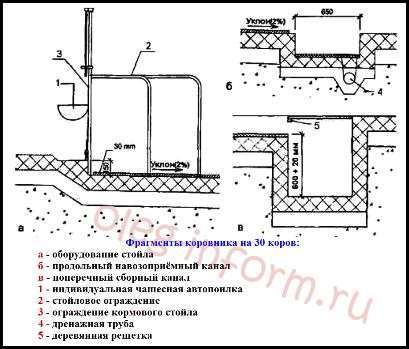

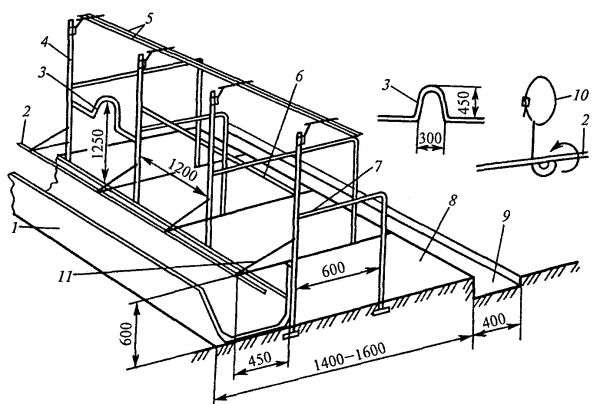

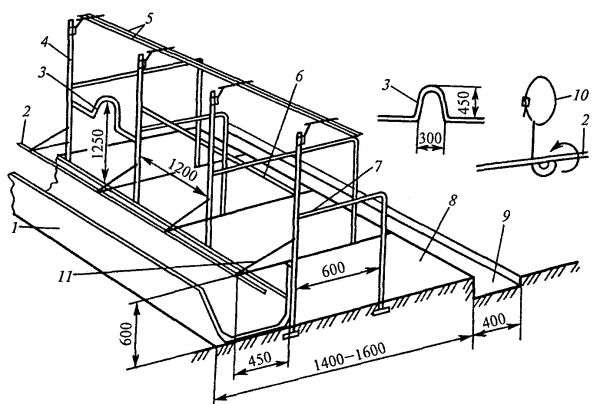

Inside the barn, stalls for cows are equipped with a length of 1.75 m and a width of 1.2 m. The stalls are fenced on the sides with two U-shaped metal arches. In the front part of the stall, there are fences that prevent the animal from entering the feeding table. A harness, vacuum and milk lines are mounted on the fence. In the rear part of the stall, a manure collection channel with a depth of 0.20 m and a width of 0.65 m is made. The resting place of the animal is made of expanded clay concrete with a two percent slope towards the manure channel and covered with a rubber mat (mattress) 30 mm thick. The enclosing structure of the feeding table does not interfere with the animal lying on the mat. At the same time, the udder of the animal is on the rug.

The fodder table, 3.6 m wide, is made of reinforced concrete and has trough-shaped recesses adjacent to the stall fences. Serves for moving the mobile feed dispenser and receiving the dispensed feed. Deepening of the feed table limits the spreading of compound feed when feeding animals

The manure receiving channels are equipped with drainage pipes for receiving and transporting the liquid fraction of the manure to the manure receiver. The transverse channel, 0.60 m deep and 0.65 wide, is covered with wooden gratings that form a slit floor. Designed to receive manure from longitudinal channels and supply it to the near-farm manure storage. The keeping of cows on the farm is tethered, without a range. Feeding of animals is of the same type, with complete feed mixtures prepared by a mixer-feeder. They are also given feed along the animal feeding front.

Animals are watered from individual auto-drinkers installed on the fence of the feeding table.At the same time, one drinker serves two cows standing next to each other. Manure is removed from the barn with a scraper installed in the manure collection channel and fed into a transverse channel made in the end part of the room. From the transverse channel, the scraper unit transports the manure to the near-farm manure storage. The cows are milked in stalls, with the collection of the obtained milk in a milk pipe, which serves it into a milk tank for cooling and short-term storage.

The required parameters of the microclimate in the barn are provided by the supply and exhaust ventilation system. At the same time, fresh air is supplied to the room through the supply ducts located in the walls of the barn, and the exhaust of polluted air is provided through the ventilation slots made along the ridge of the building. The productivity of animals on the farm is 10.0 tons of milk per year per forage cow with a fat content of 4.1 percent.

Young cattle nursery

The process of making feeders for young calves is similar, only it is necessary to provide for a folding grate that prevents adult cattle from eating feed. The length of the nursery is made a maximum of 1 m, the width is at least 40 cm.The sides are set up to 100 cm high.

The optimal material for manufacturing is boards made of hard trees. The workpieces are cut according to the individual dimensions of the drawn drawing. If we focus on the established standards, then the feeders for young calves have the following dimensions:

- inner side height - 100 cm, outer side - 30 cm;

- bottom width - 45 cm;

- trough length - 80 cm.

Having decided on the size, they begin to make the nursery for the calves.

Assembly order:

- Dry boards are sanded, sawn with a hand or circular saw. According to the drawing, shields are knocked down from the blanks, after which the trough is assembled.

- A semicircular recess is cut out on the side, making it easier for the calf to get food.

- The bars are knocked down from the bars. The width of the cells is selected so that the head of the calf does not get stuck.

Ready-made nurseries are sanded, cut off sharp edges.

Concrete - old and new solutions

According to foreign European experts who have been specializing in construction for many years livestock farms

, standard concrete structures, ubiquitous in Russia and in the countries of the former Soviet Union, are completely unsuitable for keeping highly productive animals. Concrete has a high degree of thermal conductivity. In summer, it lets in too much heat, in winter - cold. In such barns, as a rule, a lot of condensation accumulates, which occurs when the warm air rising from the cows collides with the cooled concrete. Among other things, during the tethered keeping of cows and milking in linear milk pipelines, which are still widespread in Russia, milkmaids work directly in the barn. For this reason, we have traditionally always been afraid to freeze in winter. Often the windows are completely closed in winter, the lack of supply ventilation creates a negative microclimate in the barn, high humidity and ammonia content in the air. All this contributes to the reproduction of putrefactive bacteria, leads to animal disease and, as a result, to a drop in productivity. Constantly open doors in barns do not improve the ventilation situation, but only create drafts, which is also not good for animals.

Typical mistakes when reconstructing for loose maintenance of concrete cowsheds

foreign experts also consider falling into the other extreme. Leaving the walls concrete and mindful of ventilation, our farms often open all the windows, or make “fashionable” curtains instead of windows, while opening the skylight in the roof without thinking about its width, and even keeping the doors open.With this approach, especially in the North-West region with its humidity and low temperatures in winter, and even without taking into account the productivity of cows in

cowshed

, we can get problems in the form of frozen manure, water in drinkers, etc. Western European experts view the construction of "cow dwellings" as a kind of unified system in which all the details are interconnected and very strictly tied to the local climatic conditions where the farm is being built or reconstructed.

Ventilation systems play a huge role in keeping highly productive herds on farms. When designing a new barn, or reconstructing an old one, so that natural ventilation is really supply and exhaust, such moments as the width of the barn, the height along the ridge, the angle of the roof, the number of cows, and their productivity are taken into account and subjected to a careful calculation for the ratio. The width of the ridge is done in strict proportion to many calculations.

During the renovation of our old concrete cowsheds

Western experts strongly recommend installing deflector plates under concrete ceilings to direct the air flow to the hood into the ridge and prevent cold air from sinking onto the cows.

Container for pasture

If cattle is kept in a stall-pasture system, then all feeding places must be equipped according to the rules. This is necessary to ensure maximum functionality - less feed wastage and more feed intake, as well as good capacity. At the same time, the workers do not make additional efforts.

On pastures, it is also necessary to install cattle feeders, especially during periods when the vegetation is sparse. Usually, the deficit of greenery occurs in the autumn period. Often hay is stacked in small stacks, but this option is very wasteful. The product is pulled apart or trampled into the ground.

An excellent way out of the situation will be feeders made in the form of a cone or an inverted triangle. They can be of any convenient length, and the side walls are in the form of rods. A special pallet is installed below, in which small blades of grass are collected. A roll of hay is placed in such a container and it lasts for a long time.

Feeding with grain or compound feed can also take place in walking areas. Even if greens are abundant, dairy cows and calves need additional nutrition. In this case, automatic feeders are used. The pros are that food is served continuously, but in small doses.

Wooden structures

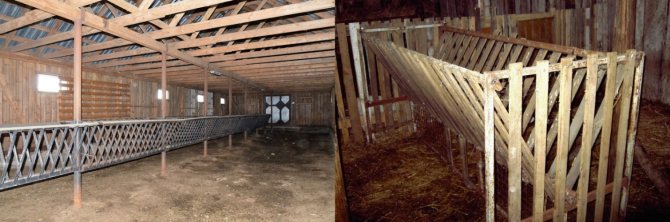

Farms built of wood are common in Europe. Wood is a good material in terms of its thermal conductivity and microclimate in the barn. One of the disadvantages of wooden barns is their fragility, given the aggressive environment.

There is a prejudice that wood is a rotting material. But, if, with the help of properly organized ventilation and technical solutions, normal indicators for temperature, relative humidity and the time of their exposure can be controlled, sufficient durability can be achieved. cowshed

... Moreover, the tree does not need to be used in all parts of the structure. The main thing is that the wooden parts do not come into contact with water and moisture. If the humidity in the barn is less than 80% for most of the year, there will be no problems with mold, rotting and corrosion of the material.

There are various designs of wooden barns, some are described in the report of the Research Institute of Agriculture Vakola (Finland).

Features of the feeder in the barn

So that during feeding and watering of livestock in the barn, food does not fall under the feet of the cows, special designs are used for feed.Usually they are made mounted, with a grate attached to the top through which the cow can get food..

Depending on the number of animals, feeders can be individual or group.

Did you know? Cows are very fond of cleanliness. Animals will not take food from a dirty trough or drink stagnant water from a drinking trough.

Brick barns

Brick cowsheds are widespread in countries with a temperate climate. This is the most proven, moreover, the most familiar building material.

I will cite the opinion of Dutch specialists, which has been specializing in the construction of livestock farms in all countries of the world for more than 40 years. One technical assignment for the construction of a farm in the Northwest region was considered, in which it was indicated that at a humidity of 90%, a temperature of 27 ° C is possible for more than two weeks. It was concluded that when building a brick farm in such climatic conditions, two-layer masonry should be used and insulation should be used between the layers. But this entails a rise in the cost of construction.

Video "Modern purchased plastic containers for cows"

In this video, you can see what modern plastic containers exist for feeding cows, as well as what they can be used for.

A cattle feeder must be reliable, functional, durable and comfortable. It is advisable to think over every detail, correctly install containers for feed and water. This will provide comfort for both the animals themselves and the farmers. Consider the features of the feeders, their varieties, the nuances of manufacturing and installation. Here are some instructions so that everyone can make a feeder with their own hands.

Capacity for food for cattle is of great importance when arranging a stall, barn. First of all, it is important to remember that different containers must be provided for dry and wet feed.

It is advisable to store hay and grass in a rectangular hinged feeder. The feed is sometimes scattered. To prevent this, farmers often make the front wall of the lattice material. In this case, the animal must necessarily be able to freely push its head between the partitions.

Large buckets, voluminous plastic containers continue to hold the leading position as feeders for wet mash. The best option is to use a corner or wall model to save space. At the moment, specialized companies provide a fairly wide range of models: they are designed for cows, horses, calves and goats.

The dimensions of the container are essential. Usually, for cattle, it is customary to use feeders with a length of 100-120 cm, no less. The width of the bottom is most often about 35-40 cm. The height of the outer side is usually made at 70-75 cm. There are a lot of ready-made containers, and you can independently make a model according to individual parameters to ensure maximum comfort.

Hygiene and usability are also important. Models with hay grates and folding side walls are in the lead here. It's great if it is possible to remove the container if necessary. In the summer, farmers wash them, dry them thoroughly in the sun, while the cattle are in the pasture.

Sandwich panels

In this case, another construction method deserves attention. cowsheds

- from sandwich panels. This material, in terms of its quality indicators, is much less conductive than brick. In addition, the galvanized sandwich coating, and on the inside of the roof, aluminum, contributes to a higher resistance to aggressive environments in

cowshed

and therefore durability. The advantage is the ease of assembly of such structures. The panels are fixed with stainless steel bolts to galvanized steel structures. Such

cowshed

, in the presence of a ready-made foundation, is assembled by two workers in two to three weeks. The windows are also made of sandwiches with a transparent three-layer polyurethane component. The mechanism for opening such windows is provided in such a way that the window itself is thus a guiding screen for air flows.

Manufacturing instruction

So, the easiest way to make a do-it-yourself cow feeder is from wooden boards. If you are not afraid to work with wood, you know how to clean it correctly, then such material will become not easy natural and clean, but also comfortable. You can use pine or oak. Today there are three types of feeders: movable, folding and lifting. We will manufacture a lifting platform with flap walls.

We need:

- wooden boards;

- woodworking tools, grinder;

- measuring tape;

- drawing;

- steel rods or wooden slats.

Manufacturing

- First, find suitable boards, dry them, clean and grind them.

- We take the drawing and set the required dimensions: the width of the bottom is 45 cm, the width of the feeder itself is 80 cm, the height of the outer side is 30 cm, the inner side is 100 cm.

- On the inner side, for the convenience of the animal, we make a small depression for the head and neck.

- After the structure itself is ready, you can make a lattice from wooden slats or steel rods. It will prevent the scattering of hay. For convenience, we provide several options for do-it-yourself feeder drawings.

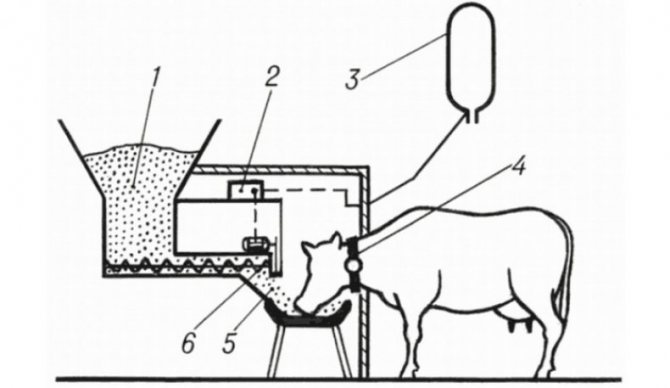

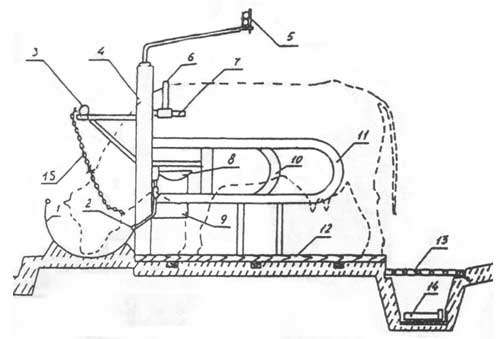

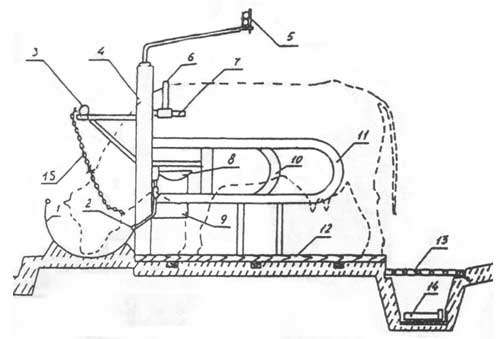

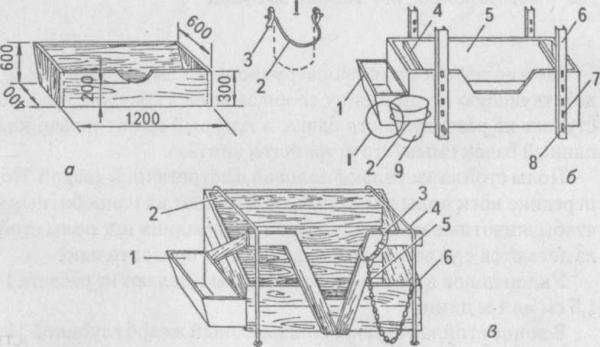

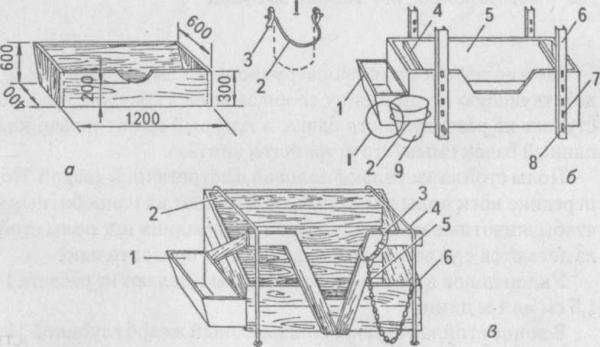

a - ground; b - height adjustable: 1 - side trough; 2, 3 - bent twig and tendril of the bucket holder; 4 - crossbar; 5 - feeder; 6 - riser; 7 - hole; 8 - stopper; 9 - bucket; в - trough-trough: 1 - side trough; 2 - feeder; 3 - collar; 4 - riser; 5 - chain; 6 - bracket

Microclimate control

Cows are known to tolerate cold better than heat, as they generate heat themselves. The more productive a cow is, the more heat it produces. It is also clear the elementary truth that the most dangerous thing for a cow is a draft. So, for example, in countries with dry warm climates, the cold way of keeping animals is very common. On such farms, instead of walls, two-layer or single-layer curtains are used, made of special high-strength polyurethane fabrics. The summer version of the curtain, as a rule, is a mesh so that birds do not fly in.

Drinker for cows

Highly productive cows during lactation are in great need of water, they need up to 100 liters of fluid per day. Based on this, it is necessary to ensure that the drinking bowls for the animals are always full so that the animals can use them safely and without hindrance. The cow especially needs liquid after milking.

There can be any container for water - even the most ordinary bucket. But the only plus of this solution is that buckets can be found in any household. There are much more disadvantages - you will have to water a cow from such a drinking bowl only in the presence of a person, the animal can easily overturn the container and pour water, besides, the volume of the bucket is very small. Better to use a large basin or trough.

On large farms, the option with a trough will also be inconvenient; it is better to make a group drinker. Typically, for these purposes, a large-diameter polypropylene pipe is used, cut lengthwise. The edges of the pipe are closed to create a lightweight, durable, hygienic container with a large volume. The cows freely approach her and drink as much as necessary. This version of the drinker can also be used on pastures where there is no possibility of running a water supply. This drinker is easy to turn over and wash when there is not much water.

Diy barn arrangement

Second layer. This is a blackout curtain in various versions and with different light and wind penetration coefficients.Automatic control of curtains with a temperature sensor is often installed: in the event of an increase in wind from any side, the curtain rises automatically without human intervention.

In sandwich-panel barns, even in cold climates, properly organized natural ventilation with well-insulated walls and roof is designed to create an ideal microclimate in the barn. In this case, the windows can be kept open all the time in winter, directed streams of fresh air and warm walls will not lead to hypothermia of the barn and provide a good microclimate.

We make containers correctly

Now we will find out how it is better to make a do-it-yourself feeder in order to get the best result at the lowest cost. We'll look at simple, affordable methods.

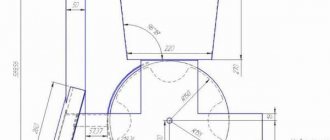

Detailed drawing

Convertible container with hinged walls

Here it is enough to have basic woodworking skills to make an excellent multifunctional feeder. You need to know how to use wood, how to clean and process this material. A comfortable container will become not only convenient, but also completely environmentally friendly. Choose a harder wood species if possible, such as oak, larch or pine.

Stock up on the following tools, as well as all the supplies you need to be productive. You will need:

- planer (you can replace it with a grinder;

- boards;

- roulette;

- hand saw (some use a jigsaw with success);

- wooden slats (but reinforcement has more strength);

- detailed drawing.

Now it's time to look at specific step-by-step instructions.

| Step | Description |

| 1 | First of all, you need to think over a work plan, complete a sufficiently detailed drawing of the future cattle feeder. Consider all the nuances, immediately calculate how it will be more convenient for you to operate the container, rinse it and fill it. The standard parameters are as follows: the height of the inner side is 100 cm, the outer side is 30 cm.The width of the bottom is 45 cm, and the width of the feeder itself is 80 cm. |

| 2 | Now choose, prepare all the building materials you need. Dry thoroughly, sand, clean the boards. |

| 3 | Details must be prepared carefully, repeating measurements twice. Then all the elements are connected. The best option is to take nails as fasteners. |

| 4 | It is necessary to make a hole in the inner flange. It is intended for the head of the animal. |

| 5 | At the final stage, wooden slats (you can use steel reinforcement) are attached to the finished structure. They are needed to save feed: animals will not be able to throw them out during the meal. Thus, the consumption will be reduced. |

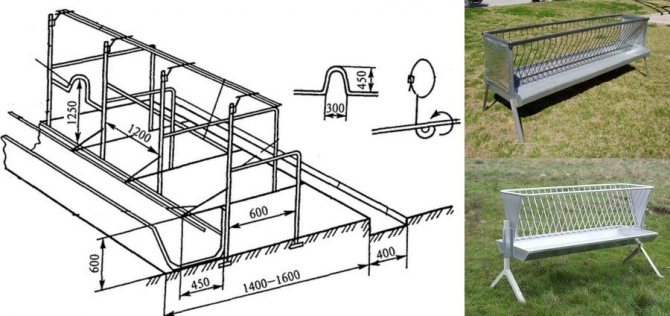

Group feeder

If the livestock is large, the best solution would be to equip a larger feeder - a group feeder. Then feeding is carried out faster, in a comfortable environment. Immediately take all the materials that will be useful for making the container. You will need:

Group capacity drawing

First, you should prepare all the elements that will then be needed when installing the model. Pipes, fittings are cut into standard parts using a grinder. Focus on the drawing. You need to make the following details:

- 13 pipes with a diameter of 19 mm, 4 pipes with a length of 68 and 35 cm, 3 pipes of 201 cm, as well as two pipes of 90 cm;

- elements from pipes with a diameter of 13 mm: two tubes with a length of 55 and 205 cm, 26 parts of 68 cm each.

When all the elements are prepared, it is time for editing.

| Step | Description |

| 1 | First of all, the frame is made. Weld pipes of 68 and 201 cm with each other in pairs. You should get a rectangle. |

| 2 | Weld the legs to the rectangle using 4 x 35 cm tubes. |

| 3 | Create stiffeners for added stability: weld a pair of 68 cm pipes between the legs. |

| 4 | In the next step, you need to install two vertical tubes of 90 and 201 cm.Two elements are attached to opposite ends, the remaining part is fixed between them. On this, the base of the trough is ready. |

| 5 | The turn of the assembly of the hay compartment comes. Weld a rectangle from 55 and 201 cm segments. |

| 6 | Weld the rectangular piece to the highest point of the vertical pipes. |

| 7 | It remains to weld the pieces of reinforcement between the pipe cut at the bottom and the rectangle. Observe a step of 7 cm. |

| 8 | Do not forget to paint the structure with a special compound to exclude quick wear and corrosion of the metal. |

The paint used for the feeders must be environmentally friendly and safe.

The correct formulation of the problem is required

As part of the Animal Management theme, it is worth discussing different approaches to the selection of stall sizes, manure and feed passages, drinking systems, stall equipment, bedding options, etc. It would seem a thousand little things, but in combination, these little things, unfortunately, can create big problems.

From what and how to build, the owner decides. Before making a decision, everyone asks themselves many questions. What do I want to get in the end? Save money today, or make a profit tomorrow? What is more profitable. to reconstruct, or to rebuild? What I want . a lot of cows or a lot of milk? For it is clear that with the right choice and adherence to technology, it is possible to achieve the same or even greater milk yield with a smaller number of livestock than with a large livestock.

OV Sakharova gene. director of NPO "Agrotekhkomplekt"

We supply frame-tent cowsheds and calf houses to all regions of Russia, Belarus and Kazakhstan: Altai Territory Barnaul Rubtsovsk Biysk Astrakhan Region Astrakhan Belgorod Region Belgorod Bryansk Region Bryansk Vladimir Region Murom Volgograd Region Volgograd Vologda Region Voronezh Region Iliyst Voronezh Irkutsk Irkutsk Region -Kut Kaluga region Kaluga Obninsk Kemerovo region Kemerovo Leninsk-Kuznetskiy Kirov region Kirov Kostroma region Kostroma Krasnodar region Novorossiysk Krasnodar Sochi Kurgan region Kurgan Kursk region Kursk Zheleznogorsk Leningrad region St. Petersburg Pushkin Tikhvin Lipetsk region Lipetsk Moscow Moscow region Sergukhvin region Nizhny Novgorod Arzamas Novgorod region Veliky Novgorod Novosibirsk region Novosibirsk Omsk region Omsk Orenburg region Orenburg Oryol region Orel Penza region Penza Perm krai Perm Solikamsk Berezniki Pskov region Pskov Velikiye Luki Rostov region Rostov-on-Don Taganrog Ryazan region Ryazan Sverdlovsk region Yekaterinburg Krasnoturinsk Serov Novouralsk Pervouralsk Alapaevsk Polevskoy Samara region Samara Tolyatti Syzran Balatiakovskaya region Stavolsk region Oblast Tver Tomsk Oblast Tomsk Tula Oblast Tula Novomoskovsk Ulyanovsk Oblast Ulyanovsk Dmitrovgrad Chelyabinsk Oblast Chelyabinsk Ozersk Zlatoust Miass Troitsk Yaroslavl Oblast Rybinsk Republic of Bashkortostan Ufa Neftekamsk Salavat Sterlitamak Oktyabrskiy Republic of Dagardi Nabaldi Makhachkala Republic of Vladivostok Almetyevsk Bugulma Republic of Udmurtia Glazov Izhevsk Votkinsk Sarapul Republic of Mari El Yoshkar-Ola.

← Back to section

The productivity and profitability of cows is largely determined by their living conditions. It is advisable to place the cowshed at a short distance from other outbuildings. A small covered room with a height of about 2.5 meters is suitable for its construction; for each adult animal, 20 sq. m. area.

Manufacturing instruction

So, the easiest way to make a do-it-yourself cow feeder is from wooden boards. If you are not afraid to work with wood, you know how to clean it correctly, then such material will become not only natural and clean, but also comfortable. You can use pine or oak. Today there are three types of feeders: movable, folding and lifting. We will manufacture a lifting one with flap walls.

We need:

- wooden boards;

- woodworking tools, grinder;

- measuring tape;

- drawing;

- steel rods or wooden slats.

Manufacturing

- First, find suitable boards, dry them, clean and grind them.

- We take the drawing and set the required dimensions: the width of the bottom is 45 cm, the width of the feeder itself is 80 cm, the height of the outer side is 30 cm, the inner side is 100 cm.

- On the inner side, for the convenience of the animal, we make a small depression for the head and neck.

- After the structure itself is ready, you can make a lattice from wooden slats or steel rods. It will prevent the scattering of hay. For convenience, we provide several options for do-it-yourself feeder drawings.

A - ground; b - height adjustable: 1 - side trough; 2, 3 - bent twig and tendril of the bucket holder; 4 - crossbar; 5 - feeder; 6 - riser; 7 - hole; 8 - stopper; 9 - bucket; в - trough-trough: 1 - side trough; 2 - feeder; 3 - collar; 4 - riser; 5 - chain; 6 - bracket

Stall for cows with their own hands

The stall for the animal must be made small, the width should be about one meter, the length should be two meters. It must be made of strong building material - hollow pipes, logs, bricks, planks or stone. The most rational option is to use logs, since they are less susceptible to the process of decay and deformation.

On the farm, a stall for an animal can be made independently with the help of bricks, if the area of the existing room is significant. To do this, it is necessary to build the base of the barn, and then lay bricks using a special solution. These stalls are popular and widely used in villages and towns, they are well ventilated and moisture does not accumulate in them.

A feeder is located in front of the structure, and a waste channel is located at the back. The channel must have the necessary level of the slope for draining into the storage tank. Above the exit of the canal from the barn, you need to build a window that will be used to clear manure. The passage to the stall should be straight, with no curved lines or curves. On the left side of the stall, with its optimal design, there should be a small free space that can be set aside for storing tanks with water or a cage with a small calf.

Requirements for cattle feeders

It is important to properly plan the place where the cattle can receive food. It must be remembered that there must be two separate containers for dry food and for wet food. You will also need to take care of the presence of a sippy cup.

In spring and summer, the cow can feed on its own, because there is a lot of grass in the pasture. There is much less food in the fall, so a special feeding area will be needed.

She must be:

- Functional.

- Roomy.

- Easy to maintain.

In this case, the loss of feed should be insignificant, and the best option would be a conical container in which a roll of hay is placed. This option is easy to assemble and not difficult to use. With the right approach to business, the cattle feeder will last a long time.

A crate with a crate is also suitable for pasture, but it is more dangerous for cows, as the head can get stuck between the branches. Alternatively, you can take a closer look at automatic structures, since they always provide access to the required amount of food.

Designing a place where cows and calves will receive feed while in the stall or pasture is very important. The main criterion is the need to have separate containers for dry and wet feed, as well as a drinking cup. Let's consider in more detail the features of different types of structures.

For pasture

While walking in the pasture in the spring and summer, the cow has the opportunity to independently obtain food for itself by eating grass. In the autumn period, certain difficulties may arise with this, therefore, farmers should consider the possibility of constructing a feeder or a platform for feeding cows, which should have the following characteristics:

- functionality;

- spaciousness;

- easy and not frequent maintenance;

- slight loss of feed.

The best option is a conical container where you can place a roll of hay. The advantage of this design is that there is little loss of dry feed, compared to stacking or just a pile of hay, since the animals eat it as needed and do not trample it into the ground. The feeder is an inverted triangle or cone structure with side walls made of twigs, into which a roll of hay is placed. At the bottom there is a pallet where small dry blades of grass are collected.

For convenience and the least loss of this type of feed, as a rule, automatic feeders are used - devices that minimize the loss of raw materials and provide access to the required amount of food. They are also indispensable helpers when raising calves in a stall.

For the stall

When organizing a place for feeding in an enclosed space, it is necessary to act, taking into account the following factors:

- number of livestock;

- type of cow keeping;

- technical or manual terms of service.

If the farm has a large number of livestock, then it is rational to use automatic feed stackers on the table, and in small ones it is more convenient to use a hinged feeder, replenishing stocks manually. To feed cows in a stall, it is necessary to create a table - a structure raised above the floor level by 15–30 cm, as a rule, fenced off with low (up to 50 cm) walls. The wall prevents dry feed from falling under the feet of the cows and also serves as a barrier to keep the table and hay clean from manure on the floor.

Hay tables, if animals are able to move freely in the barn, can be:

- vertical. Feeder with straight grates allows animals to move freely and is a more convenient design for cows;

- inclined. This design has inclined rods, cows are in a certain fixed position while eating and do not move freely;

- automatic. The most expensive design, which has such an advantage as the ability to fix the animal for veterinary examination. If necessary, the cow can be secured in one or another required position.

If the animals are in one place, it is enough to organize a simple feeder. It is worth noting the need to use different containers for different types of feed - coarse and liquid. You can make your own stall feeder.

Diy cow feeder

The feeder is made from oak or pine boards. Before its construction, the boards are cleaned, dried and sanded to avoid traumatic injuries to the animal. There are three types of feeders: lifting, folding and movable feeders.

The most effective type of design is a lifting trough with hinged walls, it allows the best way to clean the trough from food and disinfect it.For the manufacture of such a feeder, you can take the following dimensions: bottom width about 45 cm, top width - 80 cm, outer side height - 30 cm, inner side - 1 m.On the inner side of the feeder, it is necessary to make a ledge for the animal's neck.

An efficient and economical type of feeder is the structure with a grate. The grate should be the same length as the trough and a slope of about 45 degrees towards the front wall. When using this type of feeder, feed and hay are not scattered around the stall and the animal does not trample it.

Species by type of feed

The main types of feeders, taking into account the type of food - for dry feed, for grain and hay.

Hay models

Even during grazing, the animal may lack green grass. To solve this problem, equip the space with hay feeders. You should not heap the material on the ground - the cows will trample it, and the feed consumption will increase. The best option is to make a conical feeder that can hold a whole roll of dried grass. An additional advantage of the solution is that you do not need to replenish the container regularly, since the cattle will get hay gradually.

Dry food containers

Models that are easy to operate and maintain, featuring high durability and safety. The basic model is a regular square cage, but keep in mind that animals in it can be injured if they get stuck between the rods. So consider a safer "open" option whenever possible.

Grain and combined feed

For keeping at home, animals need a balanced, rich in valuable substances. For feeding grain raw materials with compound feed, it is most convenient to use automated feeders, the most practical and easy to maintain. Be sure to install them in rooms where young animals are grown - they especially need vitamins and minerals. If adult animals eat all the food, and the calves remain hungry, use drinking bowls and automatic feeders with restraints - the head of an adult animal simply will not get through them. Pay special attention to the diet and supplementary feeding of dairy cows.

But, about the correct feeding ration, you can find out here.

Barn temperature

In the process of keeping and caring for cows, it is necessary to maintain an optimal temperature in the room, since it significantly affects the metabolism of the animal. The most favorable temperature range in the barn is considered to be 10 - 20 degrees Celsius and humidity about 75%.

In the event that the temperature in the room for keeping cows is lowered relative to the required range, the metabolic processes in the animal increase, and heat production increases, as a result, the animal will require a larger volume of feed. Lower barn temperatures can also reduce milk yield.

An increase in air temperature in the barn leads to heat stress, poor appetite, changes in blood composition and an increase in respiration rate and work of the heart muscle, and ultimately decreases milk yield.

By the way, waste from raising cows (manure) can be used to supply energy to this very barn.

Required materials and tools

Nurseries are often made from wood. Excess wooden boards, perhaps, can be found in almost every personal plot, so this method is the cheapest and easiest to implement. In addition, wood is a material that is easy to use and harmless to the health of your horned animal. The most durable construction is considered to be made of pine or oak.

How to make a hanging tree feeder is a question that requires certain skills. First, let's study what tools will be needed in the process:

- wooden boards;

- measuring tape;

- blueprints;

- steel rods;

- devices for processing wood.

If you have a barn for 2 cows, then two hay feeders are made at once so that both cows have free access to green fodder. If desired, you can also build a group container.

Containers for grain and concentrates

To maintain the desired level of productivity, cows must be provided with a balanced diet, which is sufficient in trace elements and vitamins. During the summer months, when there is a large amount of green food containing nutrients, cows will still need additional nutrition.

The most rational solution is to install automatic feeders, which will provide grain and concentrated feed to animals in a strictly metered dose. The model makes it possible to practically eliminate the loss of feed, but at the same time the livestock will receive food in the right amount.

The use of auto feeders is convenient in rooms for young animals: they are the ones who need balanced feeding for growth, development and weight gain.