Spring has come, which means it's time to prepare potatoes for planting. It is believed that a potato planter can increase the productivity of the planting process by 10-20 times. This does not mean at all that this device requires a tractor or walk-behind tractor; potato planters can also be manual.

Such equipment is a necessity these days, because cultivating fields and vegetable gardens in the age of high technologies and automation with your own hands is not the most rational occupation. We will figure out how to properly make a potato planter with our own hands, get acquainted with the drawings and sizes of devices and its components.

Potato planter for walk-behind tractor Neva

Motoblock Neva is an excellent assistant when planting potatoes. To simplify this process, certain nozzles are made to the device, which are called potato planters. The most popular types of devices:

- KS-1A. The unit weighs 33 kilograms, with the passage of 1 meter, it plants 5 units of potatoes. The vegetables are placed in a bucket, where a suitable mechanism puts the tubers into the soil. The built-in cultivator then rakes in the soil and levels it out. The average cost is about 15,000 rubles.

- KS-1. This attachment is also great for the heavy Neva walk-behind tractor. Its weight is 25 kilograms. Able to plant a fifth of a hectare with potatoes in 60 minutes. Like the KS-1A model, it is produced in Russia. It can be purchased for 13,000 rubles both from the manufacturers themselves and at special points of sale or on the Internet.

- KSM-1. This is a heavier and more voluminous technique weighing up to 44 kilograms. Lands more frequently than in previous models, every 25 centimeters. The average price varies from 11,500 to 12,000 rubles.

- KST-1. It is small in size, but its main feature will be the ability to implement a variety of fertilizers into the ground at the same time as planting vegetables.

In this video, you will learn the pros and cons of a potato planter: When choosing the right potato planter, you should pay attention to the main criteria. It is necessary to decide on the required volume of the bowl and the size of the device.

By reducing the ease of transport, degradation in productivity can be promoted.

Manual

Potatoes are the most popular culture not only in our country, but all over the world. It is nutritious, tasty, but difficult to plant.

But large fields should be cultivated with agricultural machinery. So for digging and planting potatoes on a plot of 10 acres, the farmer needs to process about 20 tons of land with his own hands. This work is comparable to unloading an entire train. The easiest way to solve this unpleasant problem is to make a manual potato planter. This is a very simple device that almost anyone can do.

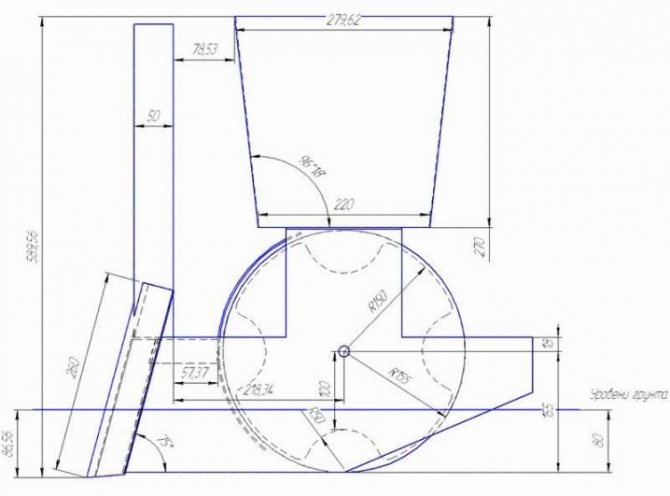

The manual device is a pipe (inside empty) with an opening at the top and a sliding valve at the bottom. For a deeper understanding (including dimensions), we will study in detail the adaptation scheme.

Crusher Drawings and Dimensions

The pipe must be cut at an angle from the bottom to form a sharp cutting, the task of which is to sink into the ground. The bevel contains a sliding valve. The task of the valve is to open only at the moment when the tuber is already inside at the required depth.

To avoid different planting depths, place a mark at the desired distance from the bevel. A special flat device that rests on the ground and does not allow the pipe to move deeper can serve as such a mark. This is very convenient, because such a limiter allows you to deepen the tuber downward, helping with your foot (like a shovel).

The upper part of the device is open, there can be a special container with potatoes and a dispenser, which does not allow sending several pieces underground at once.

The practicality of the device is its most important characteristic. Many people try to make a potato planter compact, convenient and even work on its design. This is all important, but you should never forget about the main task of the device. The potato planter should not be large and heavy, so the pipe should be taken no more than a meter in length and always thin-walled.

It should be remembered that the pipe must easily withstand immersion in the ground and pressure from the black earth, so the material must be very strong. Cooking it from a sheet of tin is not the best idea, because deformations cannot be avoided.

The valve is usually made of steel. Using a conventional door curtain, you can make a simple hinge for attaching the valve. You can make a footrest from a metal corner.

After all the components and tools are prepared, you should proceed to the direct assembly:

- Using an angle grinder (grinder), we cut the pipe at an angle, achieving optimal sharpening (the sharper the end of the pipe, the better it will enter the ground).

- We make a valve cover, which should close the pipe tightly enough at the right time.

- We fix the hinge mechanism to the pipe body.

- At a distance of 200 mm from the tip of the pipe, using welding, we install a footboard (its length corresponds to the distances between the bushes that are expected in the future).

- Handles and tubing container must be attached to the pipe (do not install a huge container).

Main characteristics of a potato planter

Potato planters for the Neva walk-behind tractor allow you to plant potatoes or harvest crops in a short time without involving human efforts. These units carry out the whole process, from cutting the furrow and tubers, planting, hilling sprouts and ending with the collection of grown vegetables.

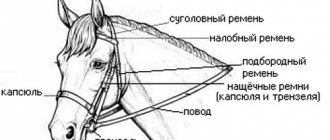

Hinged devices for a walk-behind tractor differ in both appearance and principles of operation. Planting equipment varies:

- The method of planting vegetables.

- Hopper shape for loading.

- The possession or absence of wheels.

- The number of rows.

- The possibility of simultaneously planting the introduction of fertilizers and microelements.

- Automatic and semi-automatic working principle.

Such devices have a lot of differences.

According to the method of transfer, potatoes are distributed into:

- Spoonful. Special spoons grab the vegetable and, with the help of anchors, ensure it falls out. The most common types of them are universal, capable of making furrows, planting tubers, which have the function of additional fertilization and form the required height of the ridge.

- Flat belts. The planting material is fed using a V-belt, which determines the alternating construction of the potatoes.

- Shaped. Suitable for both sprouted and non-sprouted tubers. Includes both of the previous methods.

- Multi-temporal. More functional unit. Can plant two rows of vegetables at the same time, while distributing the potatoes evenly when discarded.

- Piercing.These potato planters for a walk-behind tractor are the simplest in design, they allow you to plant fruits cut in half.

- Finger. The process takes place with the help of metal fingers that fix the tubers and send them to the disk, and then the cam mechanism feeds them for planting.

For mini tractor

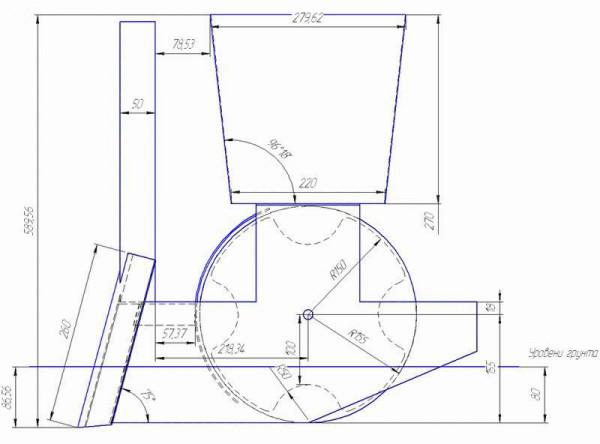

A mini tractor is already a more powerful technique and a more complex potato planter is needed for it. However, you can still use plywood - it is much lighter than steel and even aluminum, does not require welding and allows you to simply fix all the fasteners.

To create a device, you need a jigsaw. With its help, all the required parts are cut out of plywood (the optimum material thickness is 15 mm.). All components should be treated with linseed oil. When the product is ready, it should be painted with waterproof and anti-corrosion paint; oil paint is suitable for these purposes.

The container (hopper) should be abundantly pasted over from the inside with a rubber sheet or filled with silicone glue. This is done in order to avoid damage to the tubers due to friction against the wooden surface.

When the frame is ready, the holder for the openers and the axle for the future wheels of the device should be fixed to it.

Read also: Solid, strong substances with a high melting point

The axle is a thick-walled steel tube. It should be remembered that it has a very heavy load. Wheels can be used ready-made (commercially available for large carts and mini tractors) or made by yourself.

Oddly enough, but homemade wheels, as a rule, turn out to be more suitable and reliable. It's all about the design - such wheels are cylindrical in shape and are made of steel (as a rule, steel sheets are taken as a basis, bent on special machines or at home).

Holders for openers are special square rods that are assembled by welding from metal corners. Standard squares can be subject to strong deformations, which is why the most rational is the use of corners.

The planting devices of planters for tractors are pipes with a diameter of 10 cm. The pipe must have thick walls, otherwise there will be strong deformations in contact with the soil.

Also, special discs may be required to seal furrows and create ridges. For homemade planters adapted for a mini tractor, you can use the disks of the SO-4,2 seeder. The disc should be slightly modified. The holes in the hubs must be widened and the bearings must be larger. Model 160503 should be used, these bearings are ideal for the intended purpose.

Consider some of the specifics of the operation of self-made potato planters. The mass of the device turns out to be quite large, because of this, the center of mass of the device shifts to the rear. In order for the center of mass to correspond as closely as possible to the geometric center of gravity, the front of the device must be equipped with special ballasts. Farmers, who did not want to make the structure heavier again due to such a "banal" reason, subsequently complained about the loss of stability of the unit.

If there is a desire to create a device in such a way that the process of planting potato tubers takes place with maximum comfort, the planter must be equipped with seats and special adapters for the walk-behind tractor. The seat should be assembled separately and the geometry of the main frame does not need to be complicated. The seat frame is separately assembled from the metal corners, then upholstered with canvases, foam rubber and leatherette.

The rules for using homemade potato planters are no different from the rules for using factory models:

- tubers must be poured into the potato container;

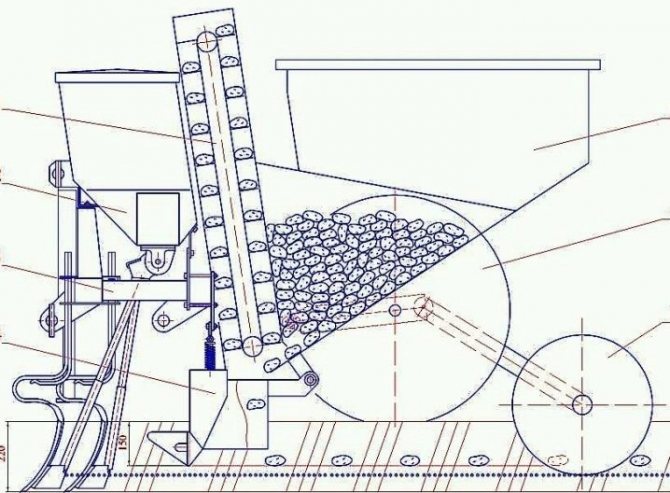

- mini tractor with a speed of 1 km / h. begins to move, the speed should not be changed, the movement should be as uniform as possible;

- the sowing mechanism delivers one potato per unit of time to the seed tube, and due to the uniformity of movement, the tubers are located along the site with an equal distance;

- with the help of special modified discs, the tubers are dusted and a special ridge is formed. Due to the angle that is formed between the discs and the furrow, the filling is carried out evenly.

Adjustment is often required. For example, when the filling of tubers is not carried out properly. Then it is necessary to adjust the angles of the discs and their distance from the hopper. By loosening the ladders and sliding the racks, you can adjust the depth of the discs. The angles of their position are regulated by changing the angle of inclination of the racks. With the help of 4 special pins, it is possible to adjust the position of the discs in the plane. Each disc can be shifted relative to the other.

Another important problem is the wheel marks that remain on the site. Despite the fact that they were manufactured with an optimal, cylindrical shape, under the pressure of the device's own weight, the wheels can compact the soil too much. To avoid such a nuisance, you can fix special paws (used in cultivation) to the potato planter. They are able to loosen the ground after the planter has passed, eliminating wheel tracks.

Planting potatoes is a very troublesome and time-consuming task. And if you have not a small plot, but a large vegetable garden, then planting these root crops turns into a rather serious challenge. That is why many are thinking about purchasing an attachment for a mini-tractor, which can greatly facilitate the work of farmers - such a device is called a "potato planter".

Hilling and care

When the first shoots appear, you need to take care of their hilling. This process can also be done using a walk-behind tractor. Hilling replaces weeding of potatoes with the Neva walk-behind tractor and loosens the soil, which helps protect tubers from low temperatures and warms them.

Various types of hillers are used with individual characteristics.

The least popular device with a constant working width. Not suitable for planting potatoes.

The hiller, in which you can change the width, is more popular. It consumes more energy, but is multifunctional.

The disc unit is in the highest price category. When used, the quality of fit is increased, which is facilitated by the ability to expose the discs at different angles.

There are also Dutch hillers. They are fuel efficient and inexpensive.

Important! It is strictly forbidden to huddle potatoes in hot weather. This causes the tuber to wilt and can harm the sprouts. The process must be carried out some time after precipitation so that the soil is saturated with moisture. This will remove excess grass and weeds without damaging the shoots.

You should not deal with potatoes with a walk-behind tractor in hot weather.

Operating rules

In order for your potato planter to serve for a long time, you should make it a habit to follow a few basic rules:

- After the end of the working day, clear the hopper, feed buckets, openers, and other elements of soil. Check and, if necessary, adjust the tension of the chain drives and mounting bolts.

- Lubricate the lower link pivots every 32 hours.

- Store the planter indoors or under a canopy during the off-season. Loosen the tension of the springs, rods, chains.

- Inspect the planter every two months.

How to make a potato planter with your own hands

A potato planter for the Neva walk-behind tractor, with certain knowledge, can be made with your own hands. For production, you will need to make:

- Ramu.

- Landing bunker.

- Implement a system of gears, with the help of which the entire mechanism is driven.

- Well preparation and burying device.

- Providing customization options.

- Wheels.

You should not try to improve the home-made unit too much, as the use of additional devices will lead to an increase in weight, and as a result, a decrease in performance and power.

The manufacturing process is as follows:

- First, the frame is mounted on wheels with two side members. A fork and an arch are placed in the front, and a support for feeding vegetables from the side. A wooden disc or gears are placed between the wheels to allow grabbing of the tubers.

- Next, a metal hopper is made, which is covered with a rubber coating, which prevents damage to the potatoes.

- Attach a metal seat or use a car seat for comfort.

- Devices for greater contact with the ground are installed on the wheels. The discs are attached to the frame using plates, bolts or brackets.

- Next is a ripper made of a bar with clips along the edge, the function of which is to hold the paws.

- Take a pipe with a diameter of 1 centimeter and make a seeding machine, to which a furrow cutter is attached.

Also, do not forget that when installing bearings, it is necessary to take into account the ingress of dust and dirt into the nodal joints.

Collecting equipment for planting and harvesting potatoes with your own hands, you not only save significant material resources, but also feel proud of the work done.

It is interesting: processing of potatoes with the Neva walk-behind tractor.

Device

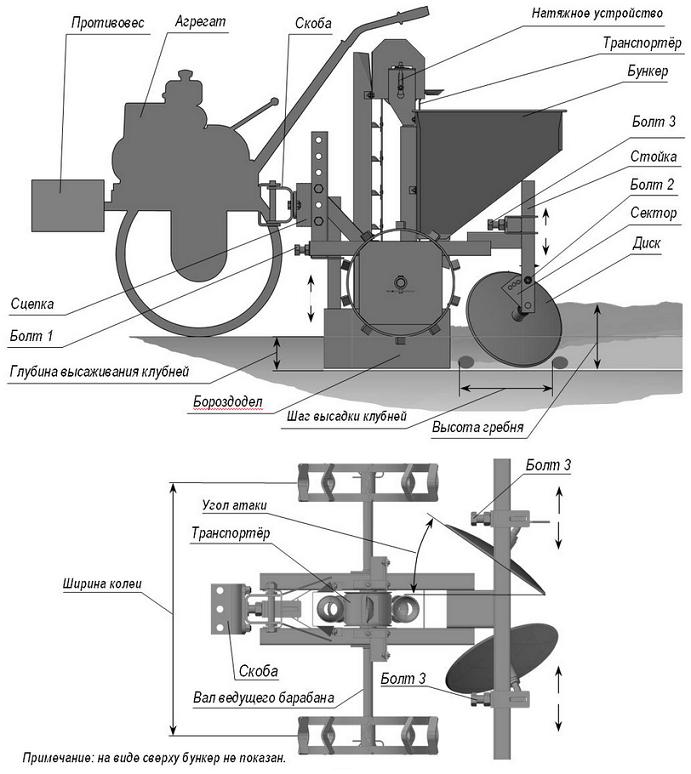

Most potato planters have the same design. It includes the following components:

- Container for potato tubers. It is made of galvanized metal, 0.6 mm thick. The hopper must hold at least 20 kg of seeds.

- Frame with wheelset. It acts as a supporting frame on which all structural elements are located.

- Support wheels. These devices are used for moving and turning.

- Openers. These devices are used to create furrows.

- Landing system drive. The device is designed for moving and planting seeds. It functions by moving the wheels, with the transfer of torque to the chain. The planting arms can be equipped with spoons or cups.

- Covering discs. These are devices for covering furrows with soil. You can buy this equipment in any specialized store, but many farmers prefer to use devices made with their own hands, since today it is not a big deal to find drawings of a homemade potato planter.

Be sure to read:

Mini tractor MTZ 082

Owner reviews

The use of this unit when planting potatoes leaves only positive feedback:

- Yuri's statement: “For health reasons, I could not start planting work manually. But this must be done. Having purchased the device, I immediately understood how to plant potatoes with a walk-behind tractor, felt the advantages in ease of use and speed of implementation. "

- Vitaly's review: “I had a walk-behind tractor, which I used only for cultivating the land. Seeing on the Internet that you can make a potato planter with your own hands, I immediately caught fire with this thought. When the work was completed, I could not get enough of my own product. Excellent cost savings and a helper in the hard work of the farmer. "