Work in the apiary is not limited only to the care of bee colonies, their reproduction and provision of everything necessary. The beekeeper also needs to collect honey on time. And, if he is the owner of a fairly large bee farm, then collecting it by hand is a very troublesome and time-consuming task. To facilitate this process, special devices are used - the so-called honey extractors.

Why do you need a honey extractor

If you only have one hive on your site, then you don't need a honey extractor. Honey can be consumed directly from the frames by breaking off the honeycomb. But in the presence of a large number of bee colonies, this equipment is simply necessary for high-quality pumping. The design is a centrifuge. The inside of the centrifuge consists of a non-moving tank (non-moving stable tank) equipped with a rotating drum.

In the drum itself there are several cassettes that rotate around their axis and correspond in size to the frames. After removing the honeycomb from the hive, they are opened and fixed on cassettes. When the rotation occurs, honey flows out of the honeycomb, and then, through a special hole, it is drained into prepared containers.

The main advantage of using a honey extractor is the ability to preserve the integrity of the honeycomb, which allows them to be reused. Falco manual is especially popular among store models. In the line of the Italian company you can find a two-frame structure and an 8-frame one. For non-standard hives, it's best to do the honey extractor yourself.

Materials you can use to make a honey extractor

The main requirements for them:

- resistance to acids;

- possibility of application for food products;

- easy care.

In order to assemble a honey extractor from wood, any dry wood other than resinous will do. It has the shape of an octagonal drum, which houses a rotating rotor with frames. Only the axle, pulleys and bearings will be metal in such a machine. The device weighs a little, it can be easily disassembled, the honey swings quickly, and the honeycomb is processed from both sides.

The plywood counterpart is lighter than the wood one; the elements are attached to glue and small nails. Making an aluminum honey extractor is as easy as shelling pears - just find a suitable barrel, tank or use the body of the washing unit. Stainless steel is a win-win option. It is practical, does not oxidize and does not rot, requires minimal maintenance, is durable and hygienic, and has no effect on the taste of honey. The body of such a honey extractor is assembled from stainless steel sheets according to the drawings, or, again, a ready-made container is used.

How a homemade honey extractor works

For a metal tank, you need to prepare a special aluminum alloy. A home-made honey extractor will have a tank at the bottom, the shape must be conical, there must be a tap in the tank, with which honey will be drained.

The stages of work of a homemade honey extractor include:

- Printing honey using a special fork.

- Placing the product in cassettes.

- The handle, which the device is equipped with, rotates, so it increases in speed.

- Due to the centrifugal force, honey from the honeycomb ends up in the tank.

- After draining, the product ends up at the bottom.

- The bottom should be equipped with a special tap, which, when opened, help the honey flow out.

Manufacturing options

The type of honey extractor is determined by the technical characteristics. So, with respect to the mechanisms for the arrangement of cassettes, they are distinguished:

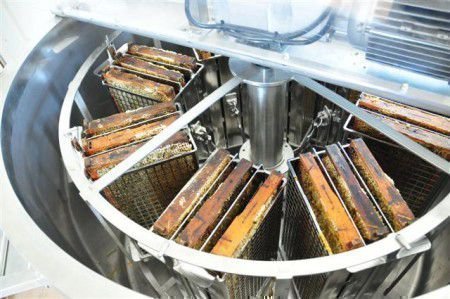

- Radial honey extractor - cassettes are located along the radial perimeter of the drum. The design allows to preserve the integrity of the honeycomb as much as possible and to pump out a large amount of honey in one go.

- Chordial honey extractor - cassettes are placed on the chords of the drum circle. The maximum number of cassettes in such installations is four. When using this type of construction, there is a high risk of damage to the honeycomb.

Jordial constructions are divided into:

- non-negotiable - honey is pumped out from one side of the honeycomb, then they are turned and the other side is emptied;

- revolving manual - hinges are mounted on the axes of the device, on which cassettes are then put on, which allows you to manually rotate the drum in one direction, then in the other direction;

- reversible - the principle of rotation is the same as in manual, only it is carried out automatically.

The second criterion that determines the type of honey extractor is the drive. It can be manual or electric.

Criterias of choice

Honey extractors differ both in the arrangement of the frames and in the type of drive. How to choose the right device for your household?

What to look for

The choice of a device for pumping honey must be carried out based on the amount of product that is planned to be obtained. For owners of a small number of bee colonies (up to 10), a two-frame chordial with a manual drive is suitable.

For those who have 30 or more hives, you can consider a four-frame. Well, if you plan to produce several tons of product, and you have more than 50 hives, you need a radial honey extractor, preferably with an electric drive.

Manual or electric honey extractor

It remains to install the drive mechanism. The question arises: which drive to choose? If your turnover in the apiary is not too high, it is better to use the manual one.

The fact is that when installing an electric motor, it is also necessary to provide for a device that will regulate the number of revolutions. This is important because at high speeds, the machine simply breaks the frames - and this is a direct loss.

After pumping out the honey, the frames are returned to the hives, where the bees re-pump them with honey, if there is a "bribe". But if it is a clean frame, the bees need time to grow the combs. Consequently, you are also wasting time and money.

Another thing is the manual drive, where you can independently regulate the work. To do it, attach the bracket to the bar. Then a curved threaded rod is threaded through it. At the end, fasten the gear with the nut.

With electric drive

In such designs, the centrifuge rotates due to operation from the mains or battery, which will be beneficial when pumping honey in the field. The electric powered honey extractor is more suitable for large apiaries producing tons of honey products.

The advantage of this design is the ability to control the speed and direction of rotation. The disadvantage is the dependence of the device on the power source, as well as the complexity of maintenance.

Without electric drive

The drum is rotated manually. This is the traditional version of the honey extractor. Its advantage is its relatively low cost and the ability to use it in any conditions. Unlike the previous model, the one under consideration does not depend on the power source. The disadvantage of this design is the low pumping speed and the difficulty in controlling the rotation speed, which can lead to damage to the honeycomb.

Design features

Depending on the frame attachment technology, the honey extractor can be made radial or chordial. In the first version, they will be placed along the radius of the circle, in the second - along its chords. The size of the honey extractor is influenced by the dimensions of the frames, the maximum diameter of the container is 65 cm.

A radial honey extractor is more productive, more reliable and will last much longer. The honey is removed from the frames so well that they remain practically clean. In such a device, the honeycombs will not stick to the frame walls; they always come out of the honey extractor intact.

Previously, the honey extractor container was most often made of wood, but gradually they switched to stainless steel and aluminum due to their improved performance characteristics. You can make a honey extractor using the tank of a worn out washing machine; it is convenient, practical and hygienically safe.

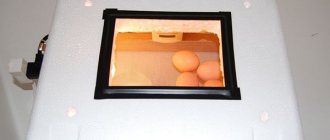

Attention! The optimal shape of the tank is cone-shaped, a lid is needed at the top to cover the contents, and at the bottom there is a hole or tap for draining the honey.

The drive train consists of bevel gears (center and side), a moving base for the subframes, and a handle that drives the gear. The drive can also be made electric, but this will greatly complicate the work.

DIY honey extractor

Honey is one of the healthiest foods around. To obtain an environmentally friendly product, it is necessary to equip an apiary with hives. Bees collecting pollen form honeycombs into frames set in the hive and lay honey.

The process of collecting honey from the obtained honeycomb is based on the centrifugation method. This requires the purchase and installation of special equipment. The cost of an industrial honey extractor is a big expense for novice beekeepers. Collecting a honey extractor with your own hands will reduce the initial costs. The need to purchase or collect such a design will be acutely felt when working with large flows of honey. The manual process will take much more time and effort and will increase the possible loss of the finished product.

The essence of the design is to use the laws of physics. The device itself includes a container for containing honeycombs. With the help of a rotor, they unwind, and honey, under the influence of centrifugal force, is thrown onto the inner surface of the tank, flowing down the walls of which, it is collected in containers specially prepared from below.

General design

Regardless of the material, the structure will generally consist of:

- cavity intended for the installation of frames;

- drive responsible for the rotation of the rotor;

- external containers for collecting honey.

There are 2 types of devices. This is a radial and chordial honey extractor. In a radial frame with honeycombs should be placed along the radius. From above, the view of the drawing resembles rays diverging from one point.

The chordial is characterized by fastening frames along the inner surface of the tank. Do-it-yourself radial honey extractor is distinguished by the ease of assembly of the structure. A homemade honey extractor will not be difficult even for beginners. The chordial, on the other hand, is more efficient for collecting honey, but it is more complex.

One of the environmentally friendly materials for collecting the honey extractor is wooden boards. First, you need to prepare cassettes that fit the frame of the honeycomb. Then assemble the wooden honey extractor. Fix the cassettes to the axle and install the entire mechanism inside the barrel. Above you need to install the handle necessary for rotation.

Attention! The inside of the barrel can be polished to protect it from decay processes.

The use of wood as a raw material is not economically justified. The high cost of the boards themselves, the need for regular treatment of the inner surface with lacquer or other moisture-protective means impose restrictions on the constant use of such an apparatus. In addition, it is necessary to equip such a honey extractor with a solid support due to the high weight of the structure itself.

Types of honey extractors

The honey extractor has a simple design, so you can easily assemble it.But first you need to decide what material to make it from. There are several options:

- Wooden container. Previously, all honey extractors were made of wood. You do not need to assemble the structure, a regular barrel is suitable for this.

- Aluminum container. An easy and practical solution. You can use a large saucepan, barrel, or tank.

- Stainless steel. For a prefabricated body, you can buy stainless steel sheets and connect them by welding. Or you can use a tank from an old washing machine. The advantages of this material are durability, strength, and easy maintenance (you can quickly wash after work).

- A plastic container can also be used. To do this, take a tank from the "Baby" washing machine or another container made of thick and durable plastic.

The dimensions of the honey extractor directly depend on the diameter of the frames with honeycombs.

The device is based on cassettes. With the help of clamps, frames with honeycombs are fixed on cassettes, the centrifuge rotates rapidly, due to which honey is extracted. It flows off the walls and goes out through the faucet into the prepared container.

Benefits

There are two types of honey extractor design - radial and chordial. We are going to make a radial, and here's why:

- The radial honey extractor provides high productivity with the same construction dimensions.

- The device, equipped with an electric motor, allows you to quickly cope with pumping and get honey. Whereas the manual drive is ineffective.

- The honey is removed from the frames so efficiently that their surface remains clean.

- Due to the construction device, only the drum rotates during operation. Therefore, the radial honey extractor is more durable and reliable.

- Frames in such a device are not damaged and do not stick to the walls. In addition, the process does not require constant supervision on your part.

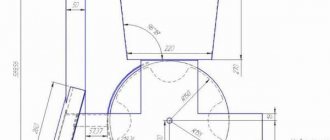

DIY honey extractor: drawings

When money is scarce, the beekeeper does not have to choose. In cases where there is not enough money for a purchased honey extractor or it is simply a pity to spend them, you can build the device yourself. The main material for creating a honey extractor is the details of the washing machine. Honey extractors are radial and electric.

Preparation of parts

It is better to initially figure out which equipment to buy and which to do it yourself. The honey extractor consists of three main parts:

- a huge container in which the rest of the materials should be placed;

- the drive mechanism, which is made of bevel gears, handles and a moving base for subframes;

- well-movable stretchers;

- cassette.

Many people will wonder why we need an old washing machine? Washing machines have huge tanks that are made of high quality stainless steel. Stuff like stainless steel, is resistant to oxide and can be easily washed from various contaminants. Therefore, we will take a washing tank as the basis for a homemade honey extractor.

Additional tools

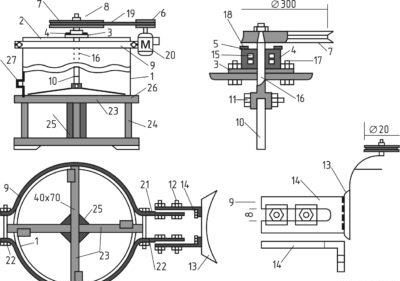

A variant of the electric honey extractor, which must be equipped with:

- 1 - tank;

- 2 - a lid that is placed on top of the tank;

- 3 - a special plate is placed down the bearing housing;

- 4 - hulls;

- 5 - cover, which must be removed;

- 6 - a leading pulley;

- 7 - driven pulley;

- 8 - with a nut for fixing;

- 9 - a clamp;

- 10 - axis;

- 11 - a bolt with which the axles will be connected;

- 12 - with bolts that secure the engine to the clamps;

- 13 - motor shoe;

- 14 - an L-shaped plate;

- 15 - bearings;

- 16 - axis;

- 17 - bolts with which it will be possible to fix the plate;

- 18 - screws suitable for removable covers;

- 19 - with a belt;

- 20 - by the engine;

- 21 - protrusions;

- 22 - with ties;

- 23 - cross support;

- 24 - uprights;

- 25 - uprights in the form of a triangle;

- 26 - tank slots;

- 27 - hole for honey drain.

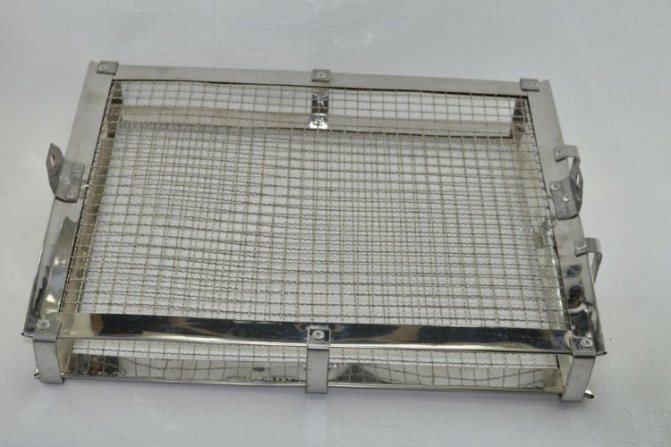

This device must be equipped with a centrifuge, cassette drum. As for the number of cassettes, their number can be any, depending on the dimensions of the device.In the design process, a metal mesh with large cells is suitable. It is easy to make a device with your own hands, you will need the necessary material and drawings.

In addition to the washing tank "Siberia" or "Alma-Ata", we will need:

- a special metal beam with certain parameters, the length of the beam will depend on the diameter of the washing tank;

- metal bracket for the drive mechanism with a thickness of 4 mm and a width of 80 mm;

- steel handle for creating rotation of the drive mechanism;

- steel base that will hold the subframes;

- two steel and wire stretchers;

- two cone-shaped gears - lateral and central;

The center gear should be larger and thicker than the side gear.

- shaft for the central gear. To create a shaft, you can use a solid and steel rod, which will withstand heavy loads and fit in diameter;

- shutter for dropping honey. You can make this part from a steel plate.

When creating the shutter, the plate is screwed at the bottom of the honey extractor and the hole for dropping honey is closed. If you don't want to do these things yourself, you can contact a locksmith asking for help. In addition to these parts, you will also need the following tools: a vise, a sledgehammer, a special lamp, an anvil, a machine for work, a grinder and welding. If you want to better understand the mechanism of the honey extractor, you can see the drawing.

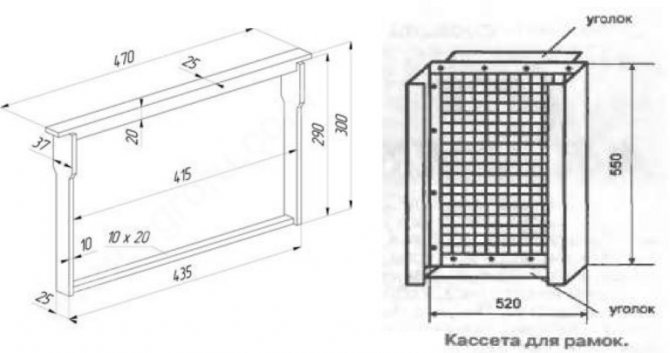

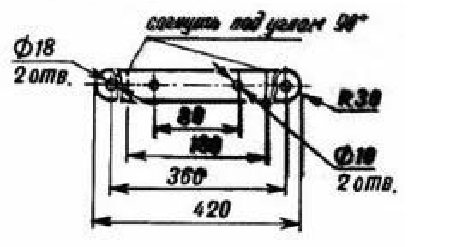

Assembling a homemade honey extractor

Making a honey extractor with your own hands is easy. In time, this process takes about 30–40 minutes. But this is provided, if you made the parts perfect for each other. Let's start by creating the stretchers. The first step will be to determine the dimensions, because the stretcher should easily accommodate special frame dimensions 435x300 mm. When creating a stretcher, you need to pay attention to the body frame. Read the drawing carefully to understand how this is done. We twist a stretcher with the required dimensions from a special corner and wire. If you want to make the frames in a standard size, it is worth reducing the dimensions of the stretcher.

What should be done

- we take two strips of steel 1 mm thick and 520 mm long. Then we add a rectangle from them and connect them with bolts;

- with a special drill we make several small holes around the perimeter of the rectangle, and then we stretch the mesh;

- create a second wire mesh and take two metal strips, and then bend two channels from it;

- between the channels, you need to fix the wire mesh and then drown out the end by welding a strip of steel;

To avoid deformation of the subframes, one metal strip should be welded to them.

- from one stretcher, we attach two brackets to the channel: one from above, the other from below;

- We do the second stretcher in the same way as the first, then put these parts aside.

The next step is to create a container for the honey extractor.

To make the washing tub ideal for the base, you need to weld unnecessary holes and holes. Worth

patch up from stainless steel sheets, and also take an electrode. After all the actions, you need to pour water into the tank. If the tank does not leak water, then you did everything right.

The next step is to arrange a special honey hole.

We take a drill and drill and make a hole in the wall of the tank, which is located at the very bottom. The required hole diameter is 25 mm. After that, we insert a rubber and tight ring into the hole. Then we take a special steel plate and make a hole in it. Later make a hole just above the drain hole of the honey extractor. We put the plate on the bolt with washers. Remember to bend the plate so you can slide it to the side when you need to open the drain. Next, bend the bar and create a few more holes.Holes should be drilled in the center of the crossbar for the center gear.

Well, the last step: we put the crossbar in the middle of the opening of the tank, divide it in half, and then outline the places where we will make the mounting holes for installing the crossbar.

- we take a hairpin and insert it into the central hole of the crossbar, put a gear on top of it and grab it with a nut;

- put the rotor on the bottom of the hairpin;

- attach the bar with a special nut;

- make a straight bar and create holes;

- insert the pins into the brackets of the subframes, fix the entire mechanism with nuts.

So the do-it-yourself honey extractor is almost ready. The connection of the drive remains. It is better to entrust this business to professionals. Yet methods are practiced creating a honey extractor using a barrel, but the process is much more complicated. How is the cassette stored? It should be stored in a safe and protected place free from moisture. The cassette is rinsed after use.

Famous honey extractors

Honey extractors are produced in a variety of types. But there are only three of the most popular brands that buyers prefer most of all.

Granovsky's honey extractor

This device can work in manual mode or on electricity and has special cassettes designed for the frame of the Dadant hive. The body and parts are made of stainless steel. The cassettes are placed on the rotor in such a way that they can be easily rotated under the action of the spring. The rotor rotates with bearings.

Granovsky's honey extractor is available in several types, depending on the number of frames. There are devices 2-frame, 3-frame for small apiaries and large ones for 8-10 frames. They are small in size, do not weigh much, work quickly and efficiently pump out honey.

Honey extractor Medunitsa

Medunitsa is one of the most famous types of honey extractors. Its devices are characterized by high quality and affordable prices. The model range is considerable, there are chordial, radial. The models also differ in the number of frames that can be fitted. For example, the model "Medunitsa 4e-220" has 4 frames (frames like Dadan), "Medunitsa-8 Combi Auto" - 8 frames. There is also a model for 24 frames.

Photo of honey extractor Lyson

Honey extractor Lyson

This is a Polish honey pumping machine. The ratio - price and quality is optimal. The Lyson honey extractor is distinguished by its simplicity of maintenance and ease of operation. It is produced in several models, which, first of all, differ in the number of fit frames.

Most of the parts are made of stainless steel. The device can operate on electricity or in manual mode, as is convenient for the beekeeper.

Making cassettes for a honey extractor with your own hands

An important element of the honey extractor is the cassettes, with their help the frames are held when honey is pumped out. To make cassettes, you need to purchase the following materials:

- Galvanized mesh with cells.

- Aluminum rivets and key.

- Special angles are required to provide side mounting on the side.

- Bulgarian.

- Welding.

- Pliers, hammer.

Honey extractor cassettes

For cassettes, it is best to use high quality stainless steel, some beekeepers use wooden blocks, plywood, ordinary iron.

The mesh is made from galvanized steel. For the frame of the cassette, you will need rods from metal, if they are not there, you can make it from wire. Pre-carefully form the mesh, then secure it by welding.

Please note that if you need to make cassettes on a large frame, they must be wide. To do this, you need to attach the tin corners up and down the cassettes, so they become reliable and rigid. You can see the parameters in the table.

Table "Dimensions of cassettes for honey extractor"

| Parameters | The size |

| Length | 50 cm |

| Width | 30 cm |

| Height | No more than 6 cm |

| Weight | Up to 1 kg. |

The design can be different, but it is important that the cassettes can be inserted into the honey extractor without any problems, the honeycomb must fit snugly to the mesh, if this rule is not followed, deformation of the honeycomb may occur when honey is pumped out.

To impregnate the inside of the cassettes, you will need to use a special drying oil, it must be resistant to moisture, covered with wax or varnish on top. It is important to thoroughly polish the device, so it will be environmentally friendly and protected from decay. It is imperative to pre-process it, so you can prevent honey from affecting the material. It will be possible to operate the device for a long time.

Proper storage of honey extractor cassettes is important

- Wash off after use.

- Stored in a safe place, which must be dry and protected from moisture and sun.

- Operate for honey extractor only.

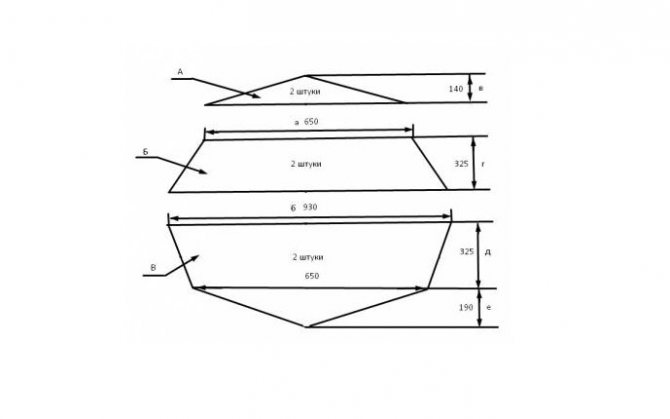

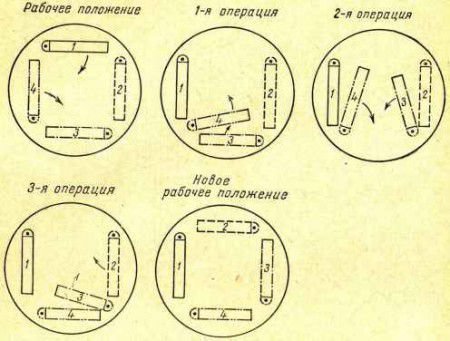

To correctly make cassettes, you need to use special drawings. Below is a drawing that makes it possible to get acquainted with the sequence of rotations of the cassettes.

Drawing "Rotations of cassettes"

Manufacturing a drive for a honey extractor

The manual work is quite complicated, so you need to pay attention to the electric honey extractor. Homemade requires a special drive. To make it, you need to follow these steps:

- Take a textolite circle 10 mm thick to make a disc on the hub.

- The drive disc can be installed by removing the pulley from the rotor.

- You can use any electric motor, 90 W is suitable, from the car stove, it is important to pre-equip it with a grid, so bees will not get inside it.

- For the switch, you can use the relay of the washing machine.

- To adjust the turnover, you can take a rheostat from any shield, in order to equip it, you will need a thick nichrome spiral.

- To attach the motor, you need to make a bracket, note that it only needs to move vertically.

It is important to use special drawings in the manufacture, a diagram is suitable with the help of it, you can make a high-quality drive. Below is a diagram showing the drive, it has a horizontal motor.

Scheme No. 1. Drive with a horizontal motor

This drive has the following advantages:

- It is possible to pump out heavy frames with honey without any problems.

- Has a power of about 90 W, the drive is powered by the car battery.

- You can select a special mode, adjust the time, revolutions.

- When manufacturing, you do not need a large amount of turner work, you will need a hub from different materials, it is best to choose birch plywood or textolite. Other parts can be purchased from a car shop.

- The drive is economical, no need to use up a lot of energy. Even if it runs all day, the engine starts without problems.

This drive also has disadvantages, so that in a horizontal position the engine is reliably engaged, you need to use a special large disc, and it can damage a large number of frames when the honey extractor inserts it into the hive. Also, sometimes it does not allow to properly insert the magazine frames for the radial mode.

Below is a diagram of a drive that has a vertical motor.

Scheme No. 2. Drive with a vertical motor

The drive is an economical device, it can be placed in a honey extractor without any problems, due to the fact that the driven disk has decreased, acceleration decreases, this problem is easy to get rid of, for this you need to control the start by hand.

Economical version of the electric drive

To save money, you need to use a small variety of details. A metal bar can be welded to the gear to fit the pulley. This will determine the control of the rotational speed. Power will be drawn from the car battery. To equip the device for pumping honey with an electric drive, you can use a transformer. If you have enough experience and skills, you can develop a speed control unit with your own hands.

Device manufacturing process

Drawing. Twelve-frame radial honey extractor

Homemade honey pumping design has excellent quality and durability. It is not difficult to make it.The design is a kind of vat. The diameter reaches 890 mm and the height is 700 mm. To make such equipment, you need to use galvanized iron. The shape is conical and the bottom is concave. Hoops are attached to the outer part, a metal cage is mounted inside, which presses the cross at the bottom.

DIY manufacturing algorithm:

- the outer part of the vat is equipped with hoops;

- the metal cage is installed inside so that it fits snugly to the bottom;

- place a glass containing a ball of steel so that the rods can hold;

- a rod is screwed into the cell axis, which can be made using a water pipe;

- at the top of the vat there is a 30 mm iron tube to prevent honey from flowing down the axis.

It should be noted that such a honey extractor is much better than a chordial one. It works more efficiently, the control unit is much more convenient and understandable.

Diy radial honey extractor: how to do it

You can buy this device ready-made in almost any special store. It will cost you no less than 40,000 rubles - a fairly serious price. Of course, it is not suitable for everyone, so the craftsmen learned how to make honey extractors radial type with his own hand. It is best to take the case to professionals or at least those who have already dealt with honey extractors. A beginner will definitely need the help of a knowledgeable person. First, you need to prepare the following tools and materials:

Making a radial honey extractor with your own hands

- The most important element and support of our work is the drawing. It is necessary to depict all the details in the correct order, and also take into account their dimensions. In addition, the drawing needs to depict the joints of the parts. If it is not possible to draw up a drawing on your own, you can find it in books on beekeeping or borrow from those who have already been engaged in the independent construction of honey extractors.

- Then we move on to the details of the honey extractor themselves. The main part is the drum, which can be any barrel made of durable material. It is best to choose a barrel with a capacity of 300-500 liters and a diameter of 100-130 cm.

- Also, depending on your choice, you will need a belt or gear pair.

- Find durable bracket material and fasteners.

- Since the honey extractor will need to be equipped with cassettes, we collect everything you need for them. You will need: cassette drum frames, cassette pipes or corners, cassette net.

- Select a suitable drain valve.

- An indispensable element of our device is bearings.

If you want to make a honey extractor equipped with an electric rather than a manual drive, then you will need an electric motor gearbox with an output of 50-100 rpm. When choosing materials, keep in mind that you have to work with products that will later be used as food. Therefore, it is important to monitor the acidic environment of the materials. The best option among the cheap ones will be stainless steel, and among the expensive ones - aluminum. After everything is prepared, we mount the structure in accordance with the drawings.

Honey extractor making tips

When making, try to be guided by following rulesto help you create a high-quality device:

The body of the future honey extractor

- In order to give the honey extractor a more aesthetic look and make it more organic, you can paint it in any color you like. For painting, it is allowed to use any paint for metal or composition in spray cans.

- Never use a zinc coating when making a honey extractor! Zinc undergoes oxidation, which can further deteriorate the quality of honey.

- Try to choose parts with a smooth surface for making a honey extractor.If the surface is rough, then honey can get stuck in it.

- You can also use wooden parts to make a honey extractor. All parts can be made of wood except for bearings, pulleys and axles. Any dry, resin-free wood will do. You can also use plywood - then the machine will be lighter.

Number of frames

We recommend reading our other articles

- Holstein breed of cows

- Apple varieties for the Urals

- White radish

- How to get rid of rats in a chicken coop?

Honey extractors come in a variety of sizes. Depending on how many frames fit in the device, it can be small or large.

- Devices with 2, 3, 4 frames, as well as 5 and 6 frames - this is the option that is suitable for a small apiary. The device is small in size, mobile, convenient in service, mainly of the chordial type.

Important!

Buying a large honey extractor for 10-20 frames is not profitable in a small apiary.

- Apparatuses for 8-16 frames are suitable for large apiaries, where it is necessary to collect honey more often and in large volumes. They can be of different types, dimensions, type of service.

- There are also professional honey extractors, in which you can install from 20 frames with honeycombs and more. These are used only in large-scale honey production. They are large, usually stationary and cost a lot, but the quality of work is excellent.

When choosing a honey extractor, it is important to decide in advance with its type, method of work, as well as how many frames will need to fit into it at a time. After that, choosing a high-quality device will no longer be difficult.

Photo of honey extractor Medunitsa

Chordial equipment

Experienced beekeepers should be aware that a chordial honey extractor can be turned into a radial honey extractor. Thanks to her, you can pump out about forty frames. However, it has drawbacks - it is not able to pump out rapeseed honey fully.

Chordial device transformation steps:

- to install the drum from below, you need to weld rings made by yourself from eight millimeter wire;

- the ring is made from above from a profile or corner, and grooves are introduced into which frames with honeycombs can be installed;

- before using the device, it is important to wash all internal parts, paint over, anoint with beeswax.

The resulting equipment has many advantages, the main one of which is that when applied, all cells and frames remain intact. The structure includes a huge drum with a lever. The drum has a metal sheet (perforated). This design prevents the penetration of foreign substances into honey. The device also includes a convenient control unit and speed control.

Honey extractor stand

The stand, at first glance, is not an obligatory element. At the same time, it still makes sense to build it, since there is nothing complicated about it, and thanks to it there will be no difficulties with installing a container for collecting honey. Of course, you can, as many do, use ordinary boxes, but such a solution cannot be called convenient. In addition, it turns out to be quite cumbersome, and, most importantly, a wobbly structure that can collapse at the most inopportune moment.

It is optimal to build a metal stand; this will require conventional fittings and a welding machine. First, a ring is made slightly larger in diameter than the honey extractor's tank, after which the legs and the holder are welded downwards. The height of the stand depends on the volume of the tank, the performance of the device and the size of the apiary.

Plastic barrel honey extractor

The cheapest option is to choose a plastic barrel as the base for your honey extractor. In addition, such a design will be the simplest option and is suitable for novice beekeepers.

Plastic has several advantages:

- not susceptible to rust;

- does not absorb odors;

- easily cleared of honey.

In addition to the plastic barrel, it is necessary to prepare: boards, metal rods, shelves and a rotating element.

A rotating element must be installed in the center of the barrel. A drill or bicycle pedal device is suitable for this. Thus, a manual honey extractor is assembled. You can use an item from an old electrical appliance. Shelves that act as cassettes should be fixed to it. As shelves, you can use ready-made shelves from the refrigerator.

Plastic barrel honey extractor

As you pedal, the cassette starts to rotate. At this time, honey from the honeycomb will fall on the walls of the barrel and flow down. Boards and metal rods are needed to fasten the tank itself.

From the washing machine

You can pump out honey by starting the drum manually, but it is better to adapt the electric motor. To do this, you need a 90 W electric motor. When using an electric drive, it is important to have a mesh that will protect insects from getting inside. A washing machine relay can serve as a switch. As a regulator of the intensity of rotations, you can use a rheostat, which should be equipped with a nichrome spiral.

Then a bracket is constructed that moves vertically. The engine itself can be placed vertically or horizontally. It all depends on your design upgrades to the honey extractor. When the electric motor is ready, you need to think about what you can do yourself and what parts you need to buy. All you need from the washing machine is a tank.

In addition to him, you will need:

- steel beam 4 mm thick, 80 mm wide, the length should correspond to the diameter of a specific tank from the washing machine;

- steel strips 2 mm thick - this will be the base for the stretchers;

- stretchers in the amount of 2 pieces, made of thin metal strips and wire;

- lateral and central bevel gears - the central gear should be larger;

- shaft for the central gear - is a carbide rod made of steel of a suitable diameter;

- steel plate, which will act as a shutter for product discharge.

The dimensions of the subframe must be calculated so that it includes a frame with dimensions of 435 × 300 mm. If a standard finished frame is used, then it will fit into such a subframe, since it has a smaller size. A 520 × 550 mm subframe must be twisted from a strip of metal and wire.

The sequence of actions is as follows:

- Take 2 stainless steel strips 1 mm thick, 520 mm long and 2 550 mm long. Fold them in a rectangle, bolt and weld.

- Using the thinnest drill bit, make many holes around the entire perimeter of the resulting rectangle.

- Make a mesh out of the wire, braiding the holes.

- Make a second of the same wire mesh.

- From 2 stainless steel strips 1 mm thick, 40 mm long, make 2 channels.

- Fasten the mesh plates between the channels.

- Blind one end of the resulting structure by welding a steel strip.

- To ensure the integrity of the structure, weld 1 metal strip across the subframe.

- On one edge of the subframe, attach the brackets above and below - they will be used as fasteners to the rotor.

- Prepare the second subframe in the same way.

Video: honey drip from the washing machine, part 1

Now you can proceed directly to the preparation of the tank. First you need to weld tightly all the holes in the tank. The patches are made from stainless steel sheets. To check the operation of the tank, at the end of welding, fill it with water to the top. If there is no leak anywhere, the job is done correctly.

Next, you need to prepare a drain hole with a diameter of 25 mm. Drill it at the very bottom of the structure with a step drill. When the hole is ready, slide the rubber O-ring over it. Then secure the metal plate against the hole so that it can be pushed aside as needed.

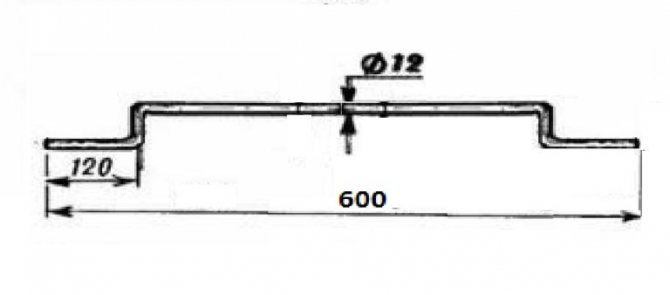

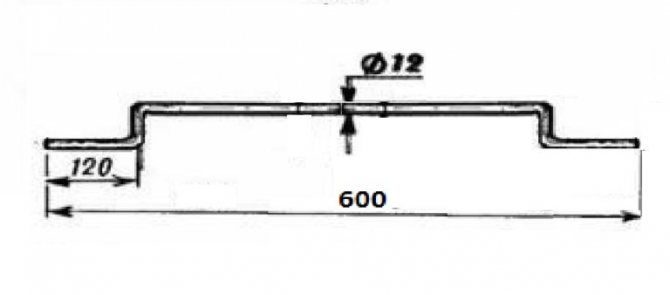

Build a crossbar for the tank. To do this, bend a 4 mm thick strip of metal along the edges with a hammer and anvil, forming the letter "P". Then drill 10 mm holes in the folded parts. In the center of the crossbar, drill a mounting hole for the center pinion shaft. The diameter of the hole should slightly exceed the diameter of the shaft by about 2–3 mm. Place the crossbar on the tank exactly in the center and mark the places for the holes on its walls. Attach the bar to the tank.

Further steps for assembling the honey extractor:

- Take a steel pin, which will be the shaft, and thread the ends at its ends.

- Insert the pin into the center hole of the crossbar, slide the center gear over it and secure them with a nut.

- Put the rotor bar on the lower part of the pin and fix it.

- At the edges of the rotor bar, make holes for the subframe pins, for which use steel rods 570 mm long. Thread the ends of the rods.

- Next, make a strip 15 mm wide, 600 mm long. Make holes at its ends.

- Insert the studs into the subframe brackets while threading them into the upper and lower rotor bars. Fix.

- Screw the drive bracket to the crossbar. Pass the curved handle-axle through the bracket, having previously cut a thread at its end.

- Slide the second gear onto the handle so that its teeth fit between the teeth of the center gear. Secure the mechanism with nuts.

Video: honeycomb from the washing machine, part 2

Preparing the bar

Use a 4mm metal strip for the crossbar. The length depends on the diameter of the tank. Drill holes around the edges so that the M10 bolt can be installed. Additionally, make two holes closer to the middle of the crossbar, as shown in the illustration.

Use a soldering iron to heat the plate and bend its edges at right angles.

Now mark the installation location on the tank. To do this, set the crossbar exactly in the center, mark with a marker the places for the holes on the tank. Drill holes in the marked places, fasten the crossbar with bolts.

Rotor bar manufacturing

Take a strip of steel 15-20 mm wide and 4 mm thick. Along the edges of the strip, you need to make a hole.

Now you need to fix the bar. To do this, make a shaft. Take a hairpin and cut a thread on it. Drill a hole in the center of the crossbar attached to the tank and install the stud. Place the bevel gear on top of the pin and grab it with a nut. Fasten the rotor bar from below and secure with a locknut.

It remains to prepare one more bar. You will need a metal strip of 600x15 mm. Make holes around the edges and bend them. Now fasten the holes of the rotor bars together with the frame brackets with studs. The movable structure is ready.

Thanks to the rotor design, the frames can be turned over from one side to the other. This allows honey to be extracted from the combs and drains the frames completely.

Stand

Be sure to make a stable stand under the tank so that you can then substitute a container for collecting honey. It can be made from a metal rod. Twist the ring from the rod so that it is slightly larger than the bottom diameter of the tank. The ends are fixed by welding. From the same rod, make as many legs and install the structure. For stability, you can weld metal strips to the legs.

The need for a stand is to install a container under the honey extractor to collect the flowing honey. For novice beekeepers, a budget option would be to use ordinary boxes or baskets. To prevent the structure from falling, you can assemble a more durable support from steel rods. It is necessary to assemble a ring with a smaller diameter than a honey extractor. By welding the holder and 3 legs from below, you can get a more stable and durable structure.