The potato digger for the walk-behind tractor is a hinged structure that allows you to quickly harvest the crop without damaging it. The equipment is actively used in large farms and small areas.

The potato digger for the walk-behind tractor has obvious advantages, it is very easy to use.

Purpose of the potato digger

A device for digging potatoes is a type of attachment. It is attached to the walk-behind tractor or fixed with a tow hitch. The purpose is to speed up the harvest. With the help of a potato digger, it is possible to select tubers on an area of 0.1-0.2 hectares in 1 hour.

In small and medium-sized areas, it is convenient to dig out potatoes with a walk-behind tractor

Manufacturers

Potato digger for MTZ walk-behind tractor

These devices are manufactured at many enterprises in Russia and the CIS countries. Below is a list of the most famous enterprises producing potato diggers:

- located in Starokonstantinov (Ukraine) produces potato digger KM-1P. This device is recognized as one of the best on the Russian and CIS market. It is certified according to all the requirements of the ISO 9001: 2009 standard.

- IE Akimov (Cheboksary, Russia) manufactures potato digger KKM-2. It is widely used by farms in Russia.

- LLC "Mechanical Plant", located in Molodechno, Belarus, produces high-quality and reliable potato digger KM and its version KM-2.

- LLC SAZ (Smorgon, Belarus) produces a digger KFT-2. This is a powerful and reliable digger, it works on the basis of the Belarus walk-behind tractor.

- LLC "Beltraktora" (Brest, Belarus) produces potato digger KT-5. Its designers are constantly working to improve the model and improve its performance.

Varieties and characteristics

There are several types of potato diggers that differ in the following parameters:

- capture width;

- design features;

- sizes;

- the ability to work in a clogged area;

- method of cleaning potatoes from soil.

All types of potato diggers are effective if the rows are straight and the row spacing is wide enough.

Screen type

The principle of operation of a roaring potato digger for a walk-behind tractor is that the flat cake sinks into the soil, captures it along with the tubers and rises. The potatoes remain on the grate, and the earth wakes up through the bars. In one pass, the device processes a small area, and this is its disadvantage.

Fan

The fan-shaped structure is also called lancet, and it is considered one of the simplest. The tiller moves along the row, and special knives cut the ground deeper than the tubers lie. The potatoes, along with the soil, move to the twigs, and the earth crumbles through them. The fan-type digger has shown itself well on loose, soft soils. The disadvantage is that the knives get stuck on an uneven area, which slows down the work.

Fan potato digger

Conveyor

The components of this digger are a moving conveyor and a flat cake. Before digging potatoes, you need to clear the area of weeds. Thick stems will wrap around moving parts and interfere with the operation of the device.

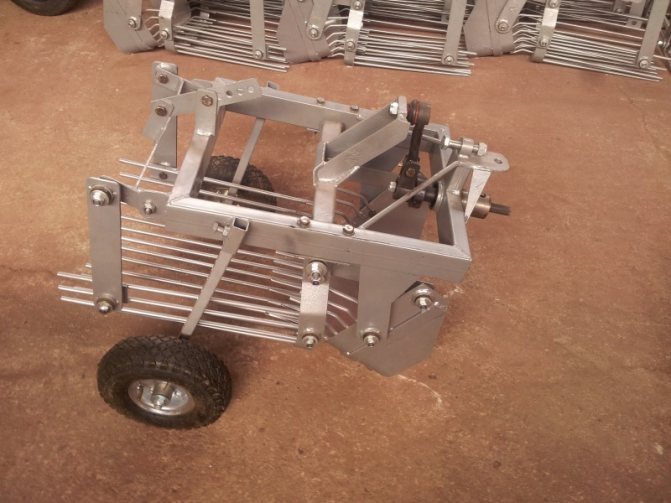

The digger is equipped with a conveyor and rear wheels - lugs. There is tension adjustment. When moving, the potatoes are shaken up, and the soil spills out from the platform.The device is connected to the walk-behind tractor with a hook element. The transporter potato digger for the walk-behind tractor is not suitable for working in wet soil.

Tympanic

The drum unit allows you to quickly dig out potatoes over large areas. Digger components:

- rotating drum;

- ploughshare (knife);

- frame;

- wheels.

A knife is attached to the frame by means of a hinge. While driving, he cuts the soil layer along with the tubers. The drum rotates, lumps break, soil particles spill through the grating bars. The potato moves to the edge of the drum and falls to the ground.

Drum Potato Digger

The knife cuts the soil so deep that it grabs all the potatoes. Moving inside the drum, tubers are not damaged. The unit is distinguished by high productivity and allows you to harvest the crop with almost no losses.

Vibrating

The experience of using a vibrating digger shows that the quality of harvesting in comparison with a simple fan-shaped digger increases by 10%.

The unit is also good in that it is easy for them to remove not only potatoes from the field, but also other vegetables:

- carrot;

- garlic;

- beets;

- onion.

A vibrating potato digger for a walk-behind tractor and MTZ is made from spare parts from a passenger car. A propeller shaft, a front wheel hub and a rear axle reducer are used. Brackets are welded to the metal base, and movable elements are attached to them.

When the walk-behind tractor is in operation, the shaft rotates, the lever and the connecting rod transmit the movement to the vibration table. The crank mechanism is connected to the traction, and the share is connected to the frame and the roar. The tubers roll and fall back or sideways, depending on where the vibrating table is tilted.

The digger is used in an area cleared of grass and haulm, otherwise the fasteners and the grate will quickly clog.

Vibrating potato digger for walk-behind tractor

Conveyor

Conveyor potato diggers are hung on walk-behind tractors and heavy equipment. They are complex in design with many moving parts. In one pass, the digger captures 2 rows, the tubers after harvesting are clean and intact, ready for laying in storage.

Types of diggers

Purchased

Production diggers for potatoes for a mini tractor differ in design from home-made devices. The most common types of purchased devices:

- Rumbling (vibrating). After grabbing the potato, it falls on the table, which gives in to vibration, shaking off soil particles.

- Conveyor. The design of the device is the same as that of a roaring digger, but a grate is installed on such a device instead of a table.

- Fan-shaped. By the principle of operation, they have similar features with a vibration analog. It is used more often not on mini tractors, but on walk-behind tractors. There are no moving elements in its design.

Homemade

A home-made digger in terms of functionality is inferior to the original products of tractor plants, it will be enough for private property. The main thing is to get the blueprints and find the necessary materials. The very process of assembling the device will not take much time. The easiest option is to make a lancet digger. By design, it is a concave shovel with long rods.

The disadvantage of harvesting potatoes with such a device is inconvenience. A person has to make fewer movements than when working with a conventional shovel. For a mini tractor, such a device is not suitable. This is a common tool change that works well in small vegetable gardens. It is difficult to dig up 1-2 km of planted beds.

A single-row mounted potato digger for a mini tractor, which you can do yourself, should be as strong and reliable as possible. The easiest way to assemble is a vibrating unit, the frame of which is made of metal corners 60 x 40 or 50 x 50. A grid can be used as a table for potatoes.

Design specifics

Before proceeding with the construction of a digger for a walk-behind tractor, you need to study its structure, understand the principle of operation, prepare materials and tools. All devices for digging potatoes function according to the same principle: the teeth cut into the soil, pick it up along with the potatoes and lift it. The soil crumbles and the potatoes roll into the bunker or fall onto the arable land.

Optimum metal thickness

Knives and other metal parts are made from steel sheets with a thickness of 8 mm. Other sizes are allowed, depending on the expected load.

Digger Wheels

The wheels of the potato digger are made movable. Those that remain from old products, for example, from a garden wheelbarrow, are suitable. It is good if they are with wide tires: this will make it easier for the mechanism to travel between rows. Wheels can be rubber, including with a protector, or metal. The first option will make it difficult to move on wet ground, the second makes it easier to move on solid ground. Tread tires are versatile - they are suitable for all types of soil.

Knives and other metal parts of the digger are made from steel sheets.

Connection methods

Parts are connected with fasteners, electric or gas welding. Bolted connections are preferable because they allow disassembly and reassembly of the unit.

How to make a homemade device with your own hands

Even a novice master will be able to make a potato digger for a walk-behind tractor with his own hands. The manufacture of the unit does not require significant financial costs. The unit turns out to be simple, so no specialists are required to repair and maintain it.

A device for digging potatoes is made from bent metal sheet and rods. Parts are welded and attached to the body. The walk-behind tractor moves, the teeth rake out the potatoes, and the earth wakes up between the rods.

When drawing up a drawing for a potato digger with your own hands, the size and type of construction are chosen based on the width of the row spacing and the planting depth.

Required tools and materials

The motoblock is equipped with a hand-made hinged potato digger, if the area of the site is measured in hundreds, and not tens of hectares. On an industrial scale, it is advisable to clean using a commercially available device.

It's easy to make a potato digger with your own hands

Materials, tools and components of the structure:

- steel or iron bars (rebar);

- channel;

- corner;

- steel with a thickness of 5-8 mm;

- laser level or square;

- fastener plates;

- nuts, bolts;

- drill, engraver;

- welding machine;

- Bulgarian;

- adjusting rod;

- suspension system;

- frame;

- lugs (wheels).

It is not necessary to buy all the parts - making a potato digger for a walk-behind tractor with your own hands is not difficult from those that were in use.

A base is made from a rectangular or square pipe

Step-by-step assembly and installation process

The peculiarity of the domestic climate is such that during the harvesting of potatoes, the soil is wet. The simplest digger will not help here - a more efficient device is required. The assembly is performed in a specific sequence.

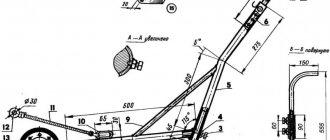

Frame

The base is made from a rectangular or square pipe with sides of 4 cm or more. The support beams are made from a 4-meter piece of metal. It is cut into lengths of 80 and 120 cm, from which a rectangular frame is welded. The corners are connected by gas or electric welding.

Rods and their fasteners

The lintels are welded to the frame, but not in the middle of the sides, but at a quarter of the length from the edge. On the back of the frame, support tubes are welded vertically, and the base for the axis is attached to them.

For fastening, nuts and bolts are used, holes are made with a drill or an engraver. Wheels are installed on the axle.

Vertical racks

A total of 3 vertical posts are made on each side of the frame.The first is 50 cm long, 5 cm from the edge of the rectangle. The second has a size of 40 cm and is 40 cm away from the first profile. The third stand is 40 cm from the second, 30 cm long. The result is a descending ladder.

In order for the unit not to collapse from heavy loads, rigidity is needed for the racks

Strengthening rigidity

The racks are reinforced with a 0.5 mm thick metal strip. In the lower part, the elements are interconnected at an angle of 45 degrees. Rigidity for the racks is needed so that the unit does not collapse from heavy loads.

Ploughshare or ralo

Ralo are made from sheet metal with a thickness of 0.3 mm. According to the drawing, the blades are cut out, and a plow is attached to them by welding. In order for the blades to better grip the ground, you need to give them a convex shape.

Pitched board manufacturing

The board, along which the tubers will roll, clearing from the soil, is also included in the design of the unit. In order not to make the structure heavier, the ramp is made of thin metal rods. Fittings with a length of 1.2 m and a diameter of 1 cm are suitable. The segments are welded at a distance of 4-5 cm from each other.

Adjustment rods

Traction rods are not required, but they facilitate the use of a potato digger for a walk-behind tractor on damp and heavy soil. Alternatively, the adjustable structure is attached to a separate frame, and it is attached to the main frame. The fasteners are tightened with bolts and nuts.

Ease of row movement depends on tire width

Support wheels

Wheels are an essential part of the potato digger. The ease of movement along the rows depends on the width of the tires: when driving, narrow wheels fall into the ground, especially if it is wet. Tires from a garden wheelbarrow or other unnecessary device will do.