Ready-made greenhouses, which are offered by modern construction companies, are so expensive that it will be even cheaper to buy a three-year crop on the market. But after all, after many programs about transgenetic fruits and vegetables, it is quite natural that the owners of personal plots in all possible ways build greenhouses from literally nothing - old window frames, pegs and even plastic pipes. Moreover, a greenhouse made of bent PVC pipes and stretched with a film looks no worse than the most beautiful finished structures, and is not inferior in quality. And it costs almost a penny. Arcs for structures can be made from almost any material. The secret is to know how. What will be discussed in this article.

The advantages of arched designs

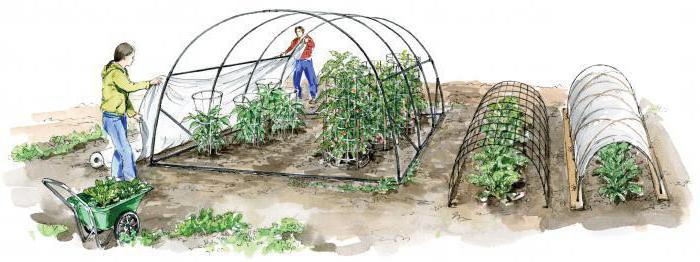

Covered with special material arc greenhouse or greenhouse are an arched structure, the size of which depends on the type of plants grown in it. Its height can be from 0.5 to 1.3 meters, and its width is from 0.6 to 1.2 meters. The length of the greenhouse depends on the number of arcs and the distance between them, so it can be any. However, a structure that is too long will not be very stable, especially in the wind.

The advantages of arc greenhouses and greenhouses include:

- High resistance to wind (provided that it is securely fastened).

- Possibility to lengthen the arched structure.

- The ability to dismantle the greenhouse and move to a new location.

- Efficient light diffusion in the greenhouse.

- Light weight, so no expensive heavy-duty foundation is required for installation.

- Lower cost and ease of installation compared to a gable roof structure.

- Ease of clearing snow in winter.

The disadvantages of such a structure:

- making arcs with your own hands is a rather difficult process;

- to strengthen the structure, you will need to install jibs and supports;

- it is possible to sheathe an arched greenhouse only with film or other material, since glass cannot be used for these purposes.

Option one

In the place where the greenhouse will stand in the future, it is necessary to drive the pins along the entire perimeter, but not very deeply. They should stick out about 15 cm from the ground. Sturdy curved tubes are fitted onto these pins. To correctly calculate how many pipes are needed? You just need to know how high the greenhouse will be. Also, the distance between PVC structures must be at least half a meter.

To strengthen the structure from top to bottom, it is necessary to lay an additional pipe and attach arcs to it.

Currently, construction companies offer a large number of ready-made greenhouses and greenhouses, but their products are so expensive that it will be cheaper to buy a three-year crop on the market. But many have seen TV shows that talked about transgenetic vegetables and fruits, so very often the owners of backyard plots try by any means to build greenhouses and greenhouses from any available materials - from plastic pipes, pegs and even old window frames.

Greenhouses and greenhouses, which are made of curved PVC pipes and covered with a film, look no worse than their most beautiful ready-made counterparts, and the quality of such a greenhouse is at the proper level.But the cost of such structures is much lower, since arches for a greenhouse and a greenhouse can be made from almost any material. The main thing is to know how to do it. This article will tell you about this.

Manufacturing of plastic arcs

The quickest and easiest way is to make arcs for a greenhouse with your own hands from water supply plastic pipes. The cost of such pipes is low, so you can not be afraid to experiment with this material.

First option. Plain

First, you need to drive in the pins for the future greenhouse around the entire perimeter, which should stick out from the ground by 15 cm, and then put on strong curved pipes on these pins. It is quite easy to calculate the required number of pipes for a greenhouse, since it depends on the distance between the arcs, which should not be less than 50 cm in order to eliminate sagging of the film, and on the height of the entire structure. In addition, it is necessary to lay another pipe at the top of the greenhouse across the arcs, which will connect all arcs and keep the greenhouse from all kinds of tilts. On top of the film, you will need to lay a masking net for plaster made of fiberglass and clamp it around the edges.

Second option. More durable

In this version, the arches for the greenhouse are made a little more complicated than in the first version, but the greenhouse built in this way will turn out to be more durable and strong.

You will need exactly the same plastic pipes, you can even use defective ones. In addition, you will need metal rods that should fit freely into the plastic pipes. For these purposes, you can use ordinary building fittings.

Next, you need to cut the rods into lengths of 60 cm.The rods will be driven into the ground by about a third of their length, so about 40 cm will remain on the surface.After all the rods are clogged, it will be possible to put prepared plastic pipes on them, the length of which should be calculated in advance - you need to take an elastic wire and ask two assistants to hold it at the edges of the greenhouse, and the third should raise its center with outstretched arms upwards - this way you will get the required arc length. In the future, the resulting wire template can be simply applied to the pipe and cut off the desired length.

Manufacturing of steel arcs

The strongest material of the frame, of course, is the metal arches for the greenhouse. But there are very few such arcs left from Soviet times, and new ones have a very high cost. But they can be made by yourself. To do this, you need a welder or a homemade machine.

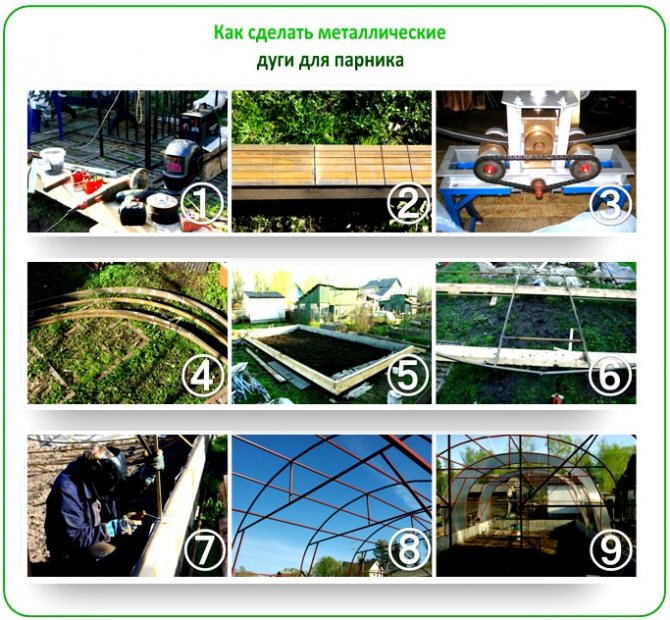

To make metal arcs for a greenhouse, you need to follow these steps:

- First, you need to experimentally determine the length of the half-arc.

- After that, two pipes should be cut, the length of each of which should be equal to the length of the half-arc.

- Then it is necessary to weld tees along the edges of the horizontal pipe that goes along the top, and then, along its entire length, weld crosses every 50 cm.

- Further, the cut parts through the crosses must be welded to the horizontal pipe that goes along the top.

- On the extreme arc, where the door will be installed in the future, two more tees should be welded at the same distance from each other so that their third hole is directed downward. Then it is necessary to weld racks to them, on which doors or vents on the other side of the greenhouse will be attached.

After that, you can begin to weld all metal arcs to the walls of the greenhouse, except for those that are on the edge. Then you need to align the greenhouse along its entire length and only then fasten it with a transverse pipe, on which there are already two tees intended for the door posts. Now all you have to do is lay the transparent film over the metal arcs.

Hose arcs

If your old hose is completely worn out, then you can make good arches from it for a greenhouse.To do this, you need to cut the hose into pieces of equal length and insert willow rods into each piece, which must be sharpened from one end in advance. The rods should be inserted into the hose with a blunt end. After that, it is necessary to fix the hose itself to the ends of the rods and bend it into an arc. At the end, you need to stick the resulting structure into the ground where you plan to install the greenhouse, install a wooden support in the middle and stretch the film over it.

If you want to build a very small greenhouse, then you can make it from 10 mm fittings. This wire is sold as a ring, so you just need to cut the ring in half to get the finished greenhouse arcs.

Frame material

The basis of the arched greenhouse is made up of flexible and strong arcs at the same time made of plastic or metal. They can be of several types:

- Polypropylene arcs can be made with your own hands from plastic pipes of the required length. When choosing pipes, you need to pay attention to the fact that they bend well.

- The metal elements for the base of the greenhouse are made from thin metal pipes in factories. You can make them yourself from thick wire.

- PVC arches are durable, lightweight and resistant to alkaline and acidic environments.

We build a greenhouse-bread bin with our own hands

Arcs for greenhouses can be made with your own hands even from wood, which will be a real exotic. However, this requires relevant skills and experience.

Expert advice

Since PVC parts are strong enough and at the same time bend well, you can make a greenhouse of any shape from them. The only thing that should be done correctly in this case is to successfully fix the structure so that it is resistant to wind and other unfavorable weather conditions.

But you should not come up with new ways of connecting the building. It is recommended not to deviate from standard templates, because as a result, the greenhouse may simply not perform its functions. It is best if you try to come up with a new type of inexpensive and convenient greenhouse from the materials available.

Making arches for a greenhouse

For the manufacture of plastic arches, you will need plastic pipes with a diameter of 20 mm. You can also use a flexible hose by first inserting a rod from a vine or a wire with a cross section of 6 mm.

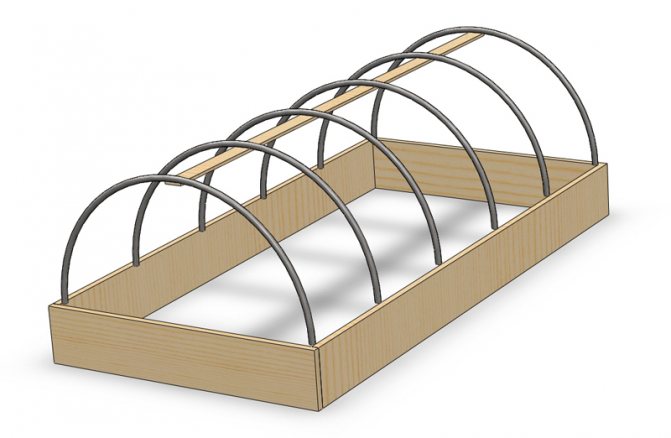

Manufacturing steps:

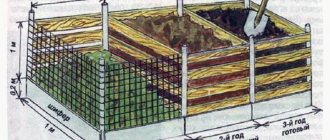

- According to the size of the beds from a wooden bar or boards, make a box with a side height of 150 mm. Oak or larch wood is less susceptible to decay.

- Install the finished frame in the designated place.

- To prevent a greenhouse from arcs under a strong wind from bending, the frame of the structure must be strengthened. To do this, in the center of the ends of the box, two racks are installed from a bar, the cross-section of which should be 50x50 mm. The racks are connected by a board, in which it is necessary to drill holes with a diameter of 2-3 mm larger than the thickness of the plastic pipes.

- Frame elements cut from pipes are inserted into each hole, which must be bent. The ends of the arcs are fixed to the box using a perforated metal mesh or clamps screwed with self-tapping screws.

- Two pieces are cut from the covering material or film to the size of the ends of the structure plus 20 cm. The film is fixed on the arc with plastic clips.

- From the material, a canvas is cut out in length for the entire greenhouse plus 50 cm for allowances. Covering film or material is laid out on the frame and fixed with clamps.

- To keep the canvas well on the arcs and not be blown away by the wind, the film can be nailed through the overhead rail to the upper wooden crossbar. The edges of the covering material are pressed to the ground by any load without sharp edges.

Use of metal

The strongest material among the others listed is metal. It can form the base of the arcs. Empirically, it is necessary to determine their length.Then you need to take a pipe, the length of which is 2 times the half-arc. This element is cut into two equal parts. It is necessary to weld tees to the horizontal pipe, which will be strengthened from above, and cross pieces along the length. The distance between them will be 0.5 m. The cut parts are welded to the pipe through the crosspiece. On the extreme arc, where the door will be installed, it is necessary to solder two tees so that they face the third hole down.

Now the elements can be welded to the walls of the greenhouse, but the extreme ones do not need to be used yet. The structure is leveled in length and fixed with a transverse pipe, where there are two tees for the door posts. Now all that remains is to cover the transparent film on top.

Durable PVC pipe greenhouses

To get a solid greenhouse of arcs, you will need some consumables and special equipment. It will be possible to fix both polyethylene film and cellular polycarbonate on such a structure.

How to build a greenhouse with your own hands from scrap materials

Manufacturing steps:

- Prepare supports from the reinforcement sections by driving them into the ground. The reinforcement should rise 25-30 cm above ground level.

- Cut two pieces of PVC pipes, each of which should be equal in length to ½ of the greenhouse arch.

- Prepare cross fittings for intermediate arches and T-shaped fittings for end arches. The inner diameter of the latter must be equal to the outer diameter of the pipes.

- Remove dirt, grease and moisture from fittings and pipe ends. In order for the pipes to hold well in the fittings, you need to make a small chamfer at their ends.

- Cold weld on the inside of the fittings and on the outside of the pipes. After that, the PVC elements are inserted into the fitting, rotated 90 degrees and fixed in a similar position for about a minute. Such actions must be carried out with your own hands with both pipes.

- The resulting structure must be carefully bent, installed on metal pins and fixed to the greenhouse foundation using screws and perforated metal tape.

Thus, from PVC pipes and fittings, strong arcs are obtained, which are securely fixed on metal supports. They will only have to be covered with a film or other material.

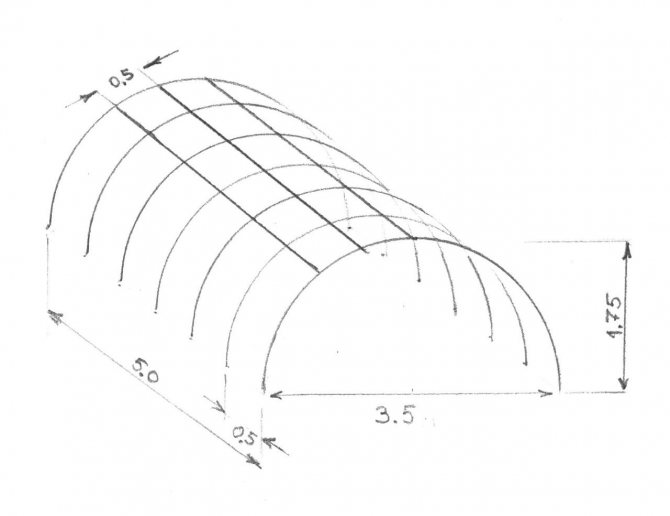

Profiled tube base

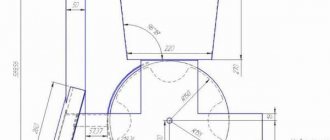

To make a greenhouse from rectangular or square shaped pipes, you will need templates or a pipe bender. When making arcs you need to be careful not to allow a violation of axial symmetry and the formation of dents on the inner wall.

Create with a template

You will need profile pipes, the cross-section of which should be no more than 20 mm.

Manufacturing process:

- Collect a piece along the length of the arc and the radius of curvature from the corner profile, plywood or wood.

- Using clamps, fix one end of the pipe on the template. It will be most convenient to do this on a workbench or a specially designated area.

- Grasping the other end of the profile element, gently and slowly bend the pipe into an arc exactly according to the pattern. This can take a lot of effort.

- The folded workpiece must be checked for defects and compared with a template. If there are no defects or they are not serious, then a hand-made part is suitable for the frame of the greenhouse.

- Make the rest of the arcs in the same way.

DIY greenhouse "butterfly" made of polycarbonate

Using the pipe bender

First of all, it is necessary decide on the length of the workpiece and the radius of its curvature. After that, you can get to work:

- Cut off the required length of the frame element from the pipe, put it on the rollers of the machine and make one roll. On the machine, you first need to select a small bend.

- Insert the workpiece with the other side and roll it again on the rollers.Such rolling is repeated until the curvature of the arc stops changing.

- The resulting part is checked against a template, and if the required radius has not been reached, a larger bend is set on the machine. After that, the pipe is again put on rollers and bent until it acquires the required radius.

The first few arcs will be trial arcs. During their bending it is recommended to mark the intermediate values of the curvature of the elements with a pencil on the jack or adjusting screw.

Manufacturers and prices

Some manufacturers offer to purchase at once the entire set for creating a greenhouse, which includes arcs, film and clamps for fastening it. But arcs sold separately are in great demand, because in this case, you can independently choose the density of the material for covering the seedlings. If necessary, arches in PVC are used for climbing roses, their stems are carefully wrapped around the arched structure and pressed to the ground. It is also important to understand how to make a polycarbonate greenhouse foundation.

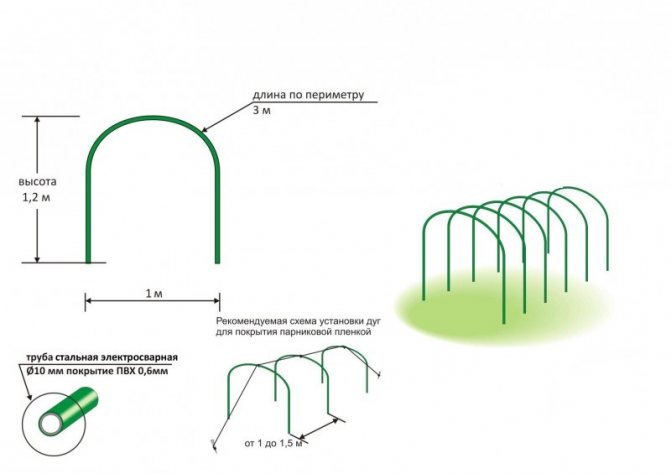

| Manufacturer | Product description | Cost, in rubles |

| LLC "Lanasad" from Tver | Pipe sets of 6:

The arches are made of a steel tube with a diameter of 10 mm, covered with green PVC (cambric). | 181 209 |

| Clover-S | Set of 6:

| 240 600 |

| Liana | The arches are 70 cm high and 100 cm wide | 520 |

Metal arcs with cuts

For the manufacture of metal arches you can use plasterboard profile, square or rectangular steel pipes.

DIY manufacturing process:

- Cut off the element from the pipe or plasterboard profile, the length of which should be equal to the length of the arc.

- Using chalk, mark the points where the cut will be made on the part. The step between the cuts should be from 150 to 250 mm.

- Clamp the workpiece with clamps or a vice on the work table and make cuts with a grinder. The plasterboard profile is cut with metal scissors. It is imperative to clean the cuts of metal residues.

- The profile will need to be bent to the required radius, for which a template can be used.

- On the arc from the profile pipe, the cuts are cleaned by welding and covered with zinc or paint to prevent corrosion.

The strength of the arc with cuts is lower than those made with a pipe bender. But if there is no machine, this method of making the frame is also suitable.

Wooden structure

For the manufacture of wooden arches do it yourself experience with wood and patience will be needed. The following materials are needed for a greenhouse:

- 42 planks of 20 mm thick boards;

- wire for making a template for the inner and outer sides of the arcs;

- self-tapping screws;

- nails;

- plywood.

Stages of work:

- Put the wire templates on the plywood and draw the outline of the arch with chalk.

- Lay the first layer out of 14 strips along the contour of the arch so that the result is an arc.

- The second layer of planks is laid on the first with an offset of ½ the length and both layers are temporarily fixed with nails. The section should be similar to brickwork.

- Of the last 14 planks, the third layer is laid, just like the first one.

- The planks are fastened together with self-tapping screws for wood. It is easier and better to do this with a screwdriver with a special attachment.

How to make your own hands a greenhouse Snowdrop 6 m

The outer edge of the arc must be rounded, and the frame can be installed at the location of the greenhouse.

The choice of covering material

An arched greenhouse or greenhouse is covered with a film or special material. He must:

- have sufficient strength for long-term operation;

- protect landings from cold air and winds as much as possible;

- good to let in the sun's rays.

These qualities are possessed by the following types of materials:

- Films for greenhouses and greenhouses. They can be of different quality, width and price.Plastic wrap is inexpensive, however, it is thin and is only used for one or two seasons. Air-bubble and reinforced film materials are stronger and more durable, withstand lower temperatures, but are more expensive than conventional film.

- Nonwovens. They are very popular among summer residents. They are produced by various companies, but all vary in thickness. The thickest has a density of 60 g / m2, and the thinnest - 17 g / m2. For sheltering greenhouses and greenhouses, it is recommended to use a material with a density of 42 g / m2, which has good qualities and excellent air permeability.

In order for the soil to warm up faster, experienced vegetable growers cover the greenhouse with foil in the spring. In this case, the seeds will sprout amicably and quickly. Then the film is removed and a nonwoven fabric is pulled over the frame. Its use excludes overheating of plants and let them breathe. It is impractical to use thin non-woven material, as it will tear quickly and may not even last until the end of the season.

So, greenhouses from arcs with a covering material can be easily made by hand. In them, garden crops will be protected from frost, winds and pests, as a result of which a large harvest with proper care is guaranteed.

Installation rules

Prepare arcs, covering material, and stones or bricks. The prepared place is dug to the required width. Depending on the design of the greenhouse, we install arcs, sticking them into the ground at a distance of 50-60 centimeters from each other, or fasten them to the prepared frame. We make additional fastenings with ropes. Wire, slats.

We cover the frame with the prepared covering material and fix it along the bottom with bricks or stones. If the structure provides for additional fasteners for the covering material, we also install them.

Your greenhouse is installed in the right place and everything is ready for planting the intended garden culture in it. Now the plants are protected from possible frost and your harvest is guaranteed.

If you find an error, please select a piece of text and press Ctrl + Enter.