If you have your own summer cottage, and you are engaged in gardening - sooner or later, you will need a greenhouse. Thanks to this simple structure, you can harvest several times a year, including in winter.

Despite the apparent simplicity, this type of work will require certain skills and knowledge. Thanks to this article, you can find out everything you need to build a greenhouse with your own hands.

Winter greenhouse device

Greenhouses can be divided into 2 groups:

- structures that have to be disassembled and hidden in the fall;

- products in which it is possible to grow plants in winter.

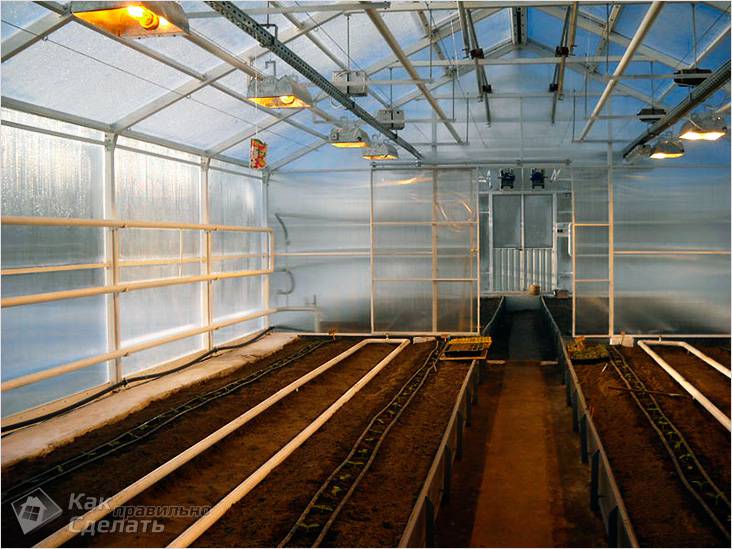

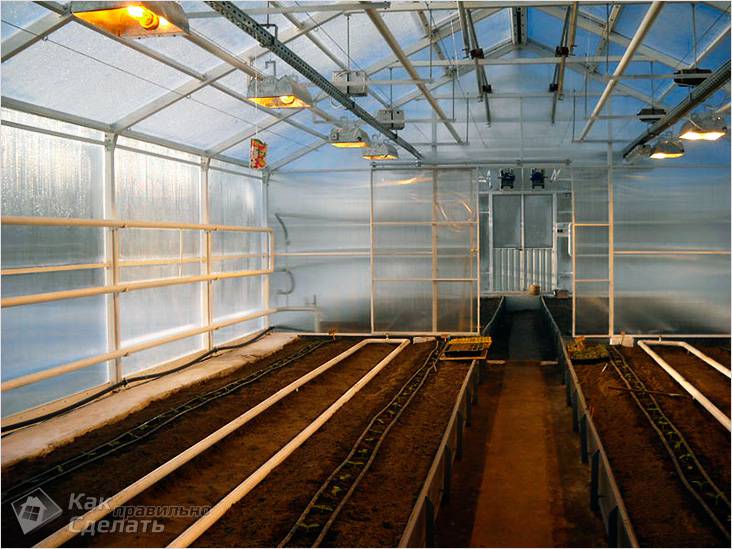

Winter greenhouses have a complex design, so it is not easy to build them yourself. They need the construction of a reliable frame, which must be located on the foundation. In addition, you will need to arrange a heating system. The efficiency of the construction depends on it. In a winter greenhouse, there must be:

- heating system;

- lighting;

- irrigation system;

- ventilation.

The dimensions of the structure are determined based on the number of crops that will be grown. It is important to use quality coating material. A thin film will not be able to keep crops from frost and snow. The advantage is additional wall insulation.

Choosing the type of heating ↑

Heating with electromatics

Before building, you also need to decide on heating. The choice of heating depends on the usable area of your greenhouse. For small rooms with an area of no more than 15-20 m², stove heating is quite suitable. For more extensive land tenure forms, we recommend paying attention to three possible options:

Photo gallery: do-it-yourself winter greenhouses - the best projects

Small polycarbonate greenhouse

Greenhouse of an unusual shape

Ventilated roof structure

Greenhouse roof made of glass and tiles

Athermal glass coated product

Plants inside the greenhouse

Greenhouse with ventilated roof

Glass covered greenhouse

Greenhouse with a high stone base

Adjoining a greenhouse to a private house

Frame structure

Winter underground structure with glass coating

Greenhouse with reinforced frame and foil cover

Metal frame for a winter greenhouse

Gable winter greenhouse

Glass-covered greenhouse

Polycarbonate Coated Greenhouse

Greenhouse covered with cellular polycarbonate

Internal arrangement of the structure

After all the construction and sealing work has been completed in full, you can proceed to the arrangement. So, it is necessary to supply water and electricity to the greenhouse for lighting. It is also important to worry about stop valves, which will ensure high-quality water supply.

When choosing sources of light scattering, it is necessary to take into account the peculiarities of growing the selected crops. An equally important issue is the soil. The substrate is prepared, fertilizers and special additives (top dressing) are applied. They will ensure fast and correct growth of all vegetables and fruits that have been selected.

Winter greenhouse

Guided by the tips given, you can build and prepare a winter greenhouse in just a few days for growing various crops in the winter. It is enough to use all available materials and purchase the missing ones. All the work can be done alone, but it is better to have an assistant, especially when it comes to assembling the skeleton of a winter greenhouse.

We recommend that you read the article "Do-it-yourself greenhouse from profile and polycarbonate".

Types of greenhouses

A greenhouse can be constructed from a variety of materials. The construction market is overflowing with a variety of coatings that are characterized by high strength, low weight and low price. This makes it possible to select materials within a small budget. At the preparation stage, you will need to create a construction plan.

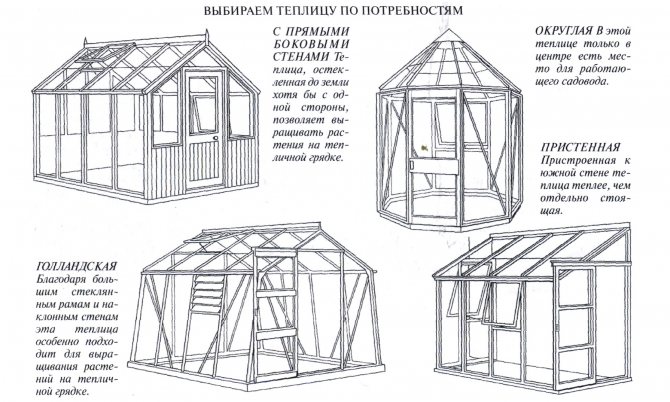

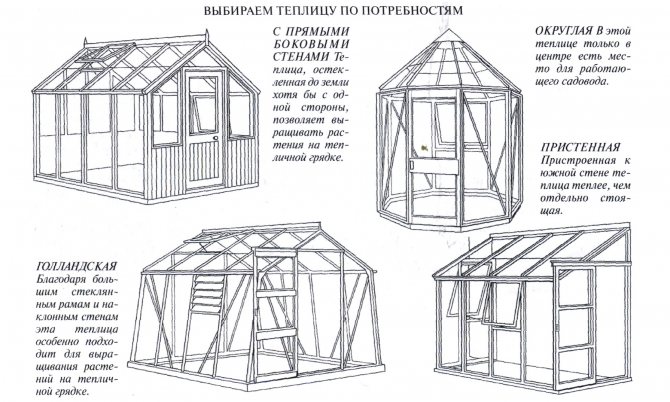

Greenhouses can be divided not only by coating materials, but also by their external shape:

- Shed product. It is wall-mounted and covered with earth.

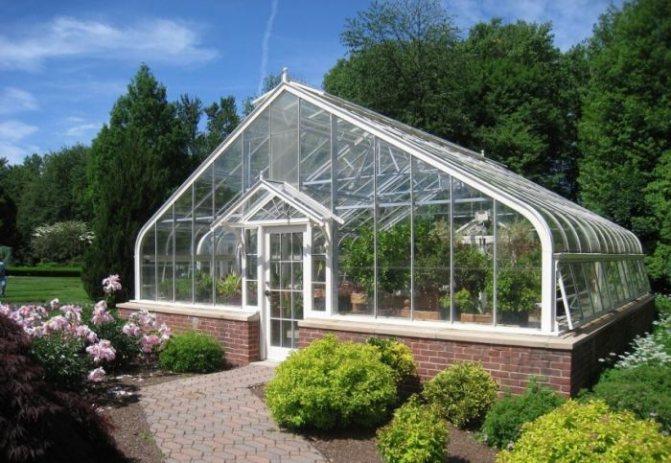

- The gable structure has main walls and a glazed roof.

- Arched structure. It can be oval and asymmetrical.

- Combined building. It can be rectangular or arched on a high base.

- Rectangular structure with an arched, pitched or gable roof.

The different shapes of greenhouses can be seen in the picture:

Greenhouses of different shapes

By location, structures can be divided into the following:

- thermos products that go deep into the soil;

- detached buildings;

- greenhouses that adjoin the main building: a bathhouse, a private house, a garage.

The latter product is capable of receiving additional heat from the common wall. As a result, it will be possible to reduce heating costs.

Design selection criteria:

- First of all, you need to calculate the parameters, since further calculation depends on them.

- It is important to take into account the functionality: first clarify the features of the plants that will be grown.

- The microclimate inside the building depends on the correct placement of the product on the ground level. If you wish, you can submerge the greenhouse underground and get the effect of a thermos. Most often, buildings are erected on the surface of the ground. Some craftsmen advise making greenhouses in old buildings (garage or barn).

A large number of architectural solutions makes it possible to embody any ideas. You can build a product with your own hands or purchase a ready-made building. Summer residents often grow flowers for sale. If the choice fell on exotic plants, then you need to calculate the costs and study the requirements for the building.

Their advantages and disadvantages

The lean-to greenhouse is a wall structure. Width varies from 2.6 to 3 m. Any length can be chosen. Glass, foil or polycarbonate can be used as the cladding material.

Single slope greenhouse adjacent to the house

The advantages of such a greenhouse:

- An excellent option for a conservatory or greenhouse, when there is a transition to a private house.

- Takes up little space.

- Low consumption of materials.

If the greenhouse is planned to be used all year round, then you will need to connect it to a centralized heating system. This may incur additional costs.

Disadvantages of the design:

- It is not possible to place the product on the north side as it will be shaded. As a result, one of the walls will be wet.

- There is much less light in the greenhouse than in a separate building. Therefore, you will need to conduct electricity and arrange powerful lighting.

The most common greenhouses are gable.

Capital gable greenhouse

All walls are at right angles to the soil. The optimal angle of inclination of the roof is 30–40 °.

Product advantages:

- Possibility to set any ridge height. The height of the roof will depend on the width of the building.

- If the shape of the house is chosen, then tall plants can be grown in the greenhouse.

- It is possible to use polycarbonate for coating. Accordingly, there is no need to arrange the foundation.

- It is possible to install vents in the roof.

- More air volume with constant dimensions.

Disadvantages:

- If the product is covered with glass, then you will need to make a foundation.

- There is no way to redevelop the site in the future, since the weight of the structure is large due to the foundation.

- A large number of joints, which has a negative effect on the ability to retain heat. The problem can be solved by installing rubber gaskets.

- Large consumption of materials when compared with an arched building.

- The need to use thick polycarbonate.

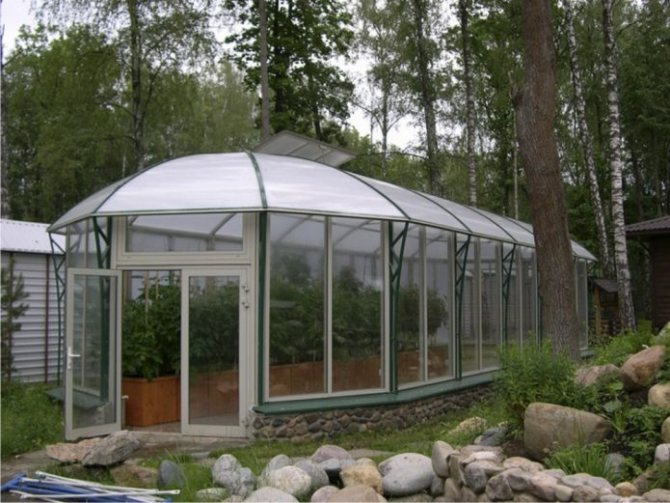

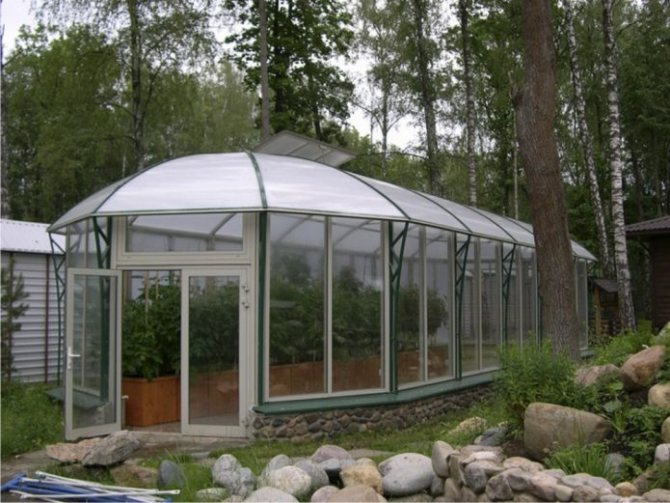

In some cases, summer residents erect an arched structure.

Arched construction with polycarbonate coating

The frame has an arc shape. You can choose any length. The maximum height is 2 m.

The advantages of an arched building:

- Ease of installation.

- Possibility to extend the length.

- Low consumption of coating material. Polycarbonate is applied with a continuous sheet.

- The minimum number of seams.

- There is no need to build a foundation.

- Low cost.

- The ability to dismantle.

- High strength.

The disadvantages include:

- Limited height. If you need a greenhouse with a height of more than 2 m, then you will need to strengthen the frame.

- Low resistance to strong winds and snow.

- It is impossible to arrange roof vents.

The choice of form depends to a large extent on the personal preferences of the summer resident.

growing cucumbers in winter

Reviews:

Artem Trofimov

writes: Hello. Please tell me how often you change the soil of the beds?

Lord master

writes: GOOD DAY. WHAT HUMIDITY IS OPTIMAL FOR CUCUMBER. AND WHAT HAPPENS TO IT WHEN CHANGING IT ON THERE OR ANOTHER SIDE?

CIRCUS SPECTATOR

writes: Please tell me, is it possible to grow cucumbers in a completely closed room (without the sun) ?? There is just a room, 300 sq. meters. It is easy to maintain heat and humidity there, but there is no sunlight. Thank you.

Pete Gavrilov

writes: Yes-ah! I really thought that really growing cucumbers in winter, some kind of unusual heating system, heating the earth ?! And here is a loud name, but in fact, it's just zilch ... There will be no heating, the end of cucumbers, even on the table?!:((((

Zhainar Ryskeldin

writes: which variety is more cool, shade-tolerant, and gives more yield (for example, I heard from one bush you can harvest up to 11 kg.) winter time?

Determination of the dimensions of the structure

To draw up a drawing, you will need to determine the dimensions of the greenhouse.

What should be the width?

Width is the main indicator in the process of determining the dimensions of the structure. In a narrow building, keeping track of plants is problematic. The width of the greenhouse should be such that the product is comfortable to use.

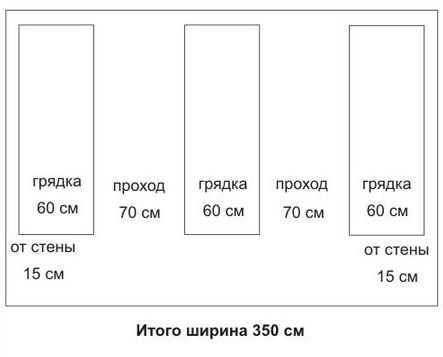

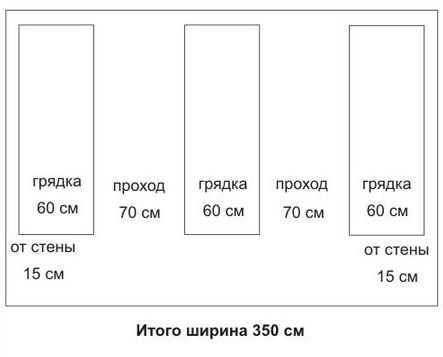

Layout of beds for a greenhouse with an optimal width

In addition, this indicator will also depend on how many beds you need to plant. The distance between the rows also influences. For example, if the beds are wide, then it is quite difficult to reach the extreme point in the process of watering the plants. If the beds are small, then the useful area will be lost on the paths.

The practice of summer residents with extensive experience shows that the best option is when several beds are 80–85 cm, and the passage between them is 35–45 cm. Based on these indicators, the recommended width of the greenhouse will be 2.4–2.6 m. If you need to make not 2, but 3 beds, then the width of the product should be 3–3.4 m. In this case, the width of the beds will be 50–60 cm, and the distance between the beds is 65–70 cm.

The minimum width of the greenhouse is 2.4 m. The width of the door must be taken into account. The optimal size is 60 cm. This passage will provide a comfortable movement for the summer resident.If you plan to use a wheelbarrow, then you will need to make the door wider - about 90 cm.

In some cases, a building is made with several aisles and a central rack with a width of about 95 cm. The width of such a structure should be 3.8–4.2 m.

Determination of the length of the structure

This parameter has no effect on anything, it can be anything. Most often, greenhouses are built so that it is a multiple of 60 or 120 cm. In this case, it will be possible to easily attach the floor panels, which are manufactured in a standard size.

In the process of determining the length, you need to take into account the number and size of pallets that you want to place on the rack. Therefore, the length of the building must correspond to the length of the shelves that are located on them. It is also important to take into account the area that is needed for the tracks along the two ends of the shelves.

Optimal building height

It is important that there is little space left between the plants that are placed in the soil or on racks, while the summer resident has enough space for convenient maintenance.

For example, if it is planned to grow small plants in the ground, then the height of the greenhouse from the upper door cornice to the ceiling will be 40–60 cm. If you want to grow plants on racks, then the dimensions of the shelves must be added to the height.

Important: the height of the greenhouse ridge must be greater than the given value of the side walls. If the height in the ridge is 2.3–2.4 m, then in the cornice it will be 1.6–1.7 m.

The height of the door must be matched to the average height of the user. Most often, the value is 1.8 m.

The main types of premises

Winter greenhouses differ from each other in many ways. For example:

- By functionality. Preference for this or that design can be given depending on what exactly will be grown in it: flowers, herbs, grapes or exotic fruits.

- At the location. Greenhouses must be built on the surface of the intended area, deepened into the soil, or created on top of an existing yard building (barn, bathhouse, garage).

- By type of heating. The plant is allowed to be heated with wood, water, biofuel or electricity.

You can also distinguish buildings by architectural features. All designs are divided into:

- Wall mounted. It is good to use them for a vegetable garden and a winter garden. The presence of a common wall helps to significantly reduce the cost of the construction process.

- Arched. The traditional dimensions of such buildings are 2 * 4 * 3 meters. It is good to grow undersized plants, vegetables and various greens in them. Such greenhouses are definitely not suitable for growing climbing crops and tall plants.

- Structures with a gable, gable or gable roof.

- Farm buildings. These are multifunctional devices that are designed for year-round use in almost any climatic zone. They are large in size, in some cases they form whole small plantations that help to grow a large volume of production (not only in the ground, but also hydroponically).

Whatever the configuration, you need to remember that a greenhouse in winter is a good structure with additional lighting and heating. I must say that its construction costs quite a lot. On the other hand, having spent your efforts and money once, you will enjoy delicious and high-quality products for many years throughout the year, and not only in summer.

The result of your work will directly depend not on the weather and soil on the site, but only on your efforts and skills.

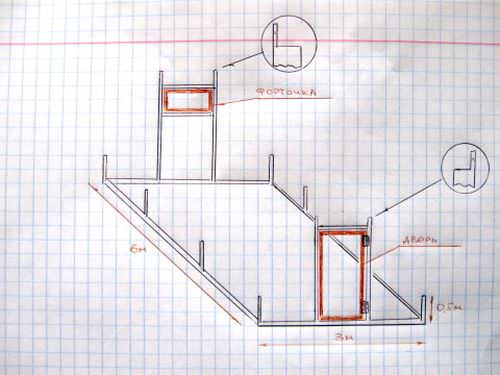

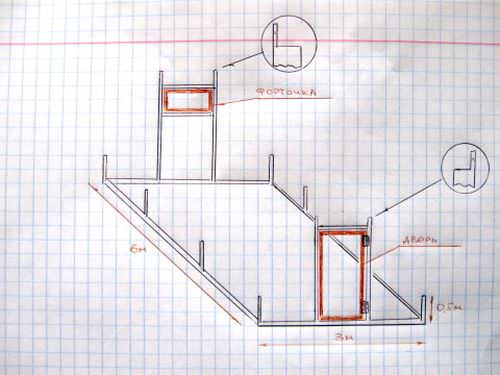

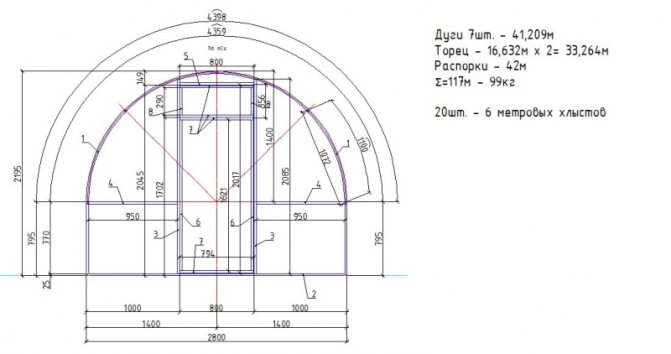

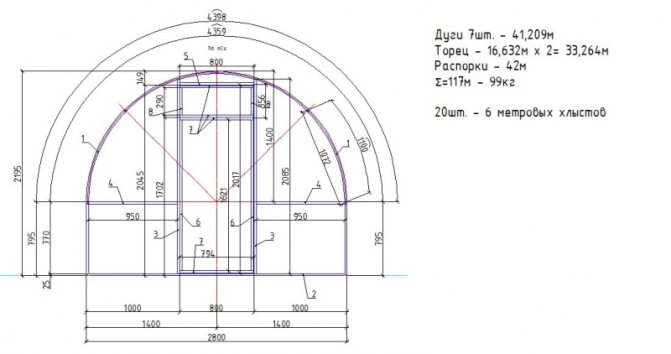

Drawing up a diagram, drawings

On the diagram, you need to indicate the length, width and height that were calculated earlier.

A competent drawing is based on the shape and dimensions of the structure, and the construction scheme should be based on the requirements that apply to this structure and the purpose of its application.It is recommended to take the photo and dimensions of the finished greenhouse frames as a basis or draw up a greenhouse project yourself.

An example of a competent drawing

Ready-made structures, which are manufactured at the factory, imply full compliance of the used material and frame with the main load and conditions of use. The diagram of a product, which is being built with your own hands, should be based on similar rules.

The technology for drawing up a design diagram implies compliance with the following features:

- The frame in most cases is made of pipes or metal profiles. This is the best option for such structures.

- Lumber absorbs moisture, so it is not recommended to use them for making the frame.

- If for some reason it was decided to use wood, then it is imperative to treat it with an antiseptic and apply a layer of varnish that can extend the life of the structure.

- The product diagram must be drawn up in accordance with the calculation of the characteristics of possible loads on the frame structure and coating. It is important to consider wind and snow loads.

- If the scheme does not imply the manufacture of a solid frame, then the product needs to be cleaned of snow from time to time in winter. Such a frame structure is cheaper, but less practical.

The frame of the building can be made of the following materials:

- aluminum;

- steel;

- wood;

- plastic.

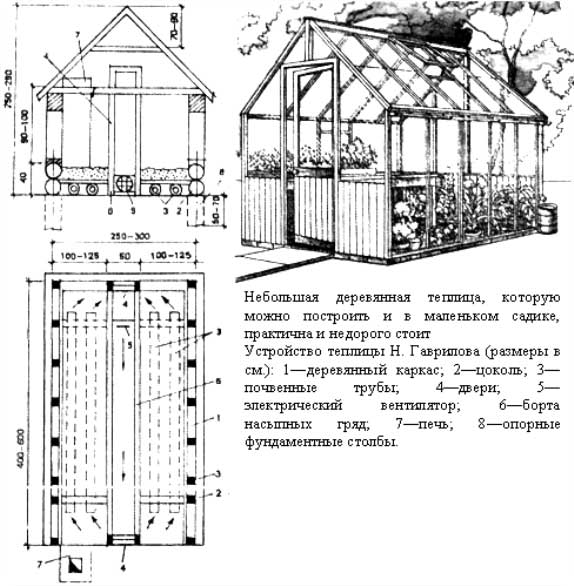

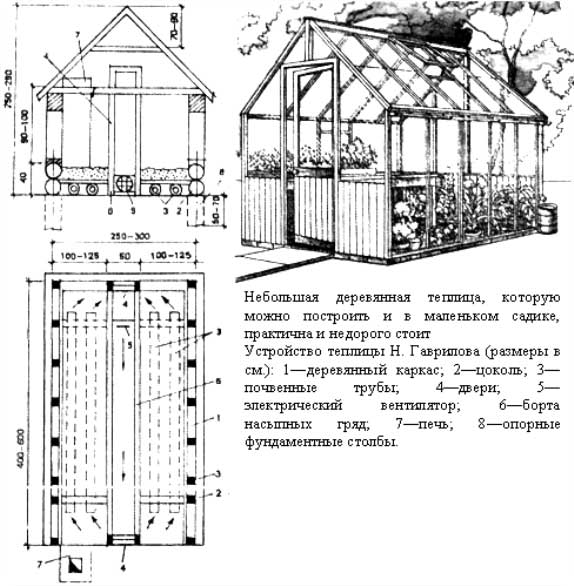

Small greenhouse frame diagram

It is important to carefully consider how the heating system will be placed.

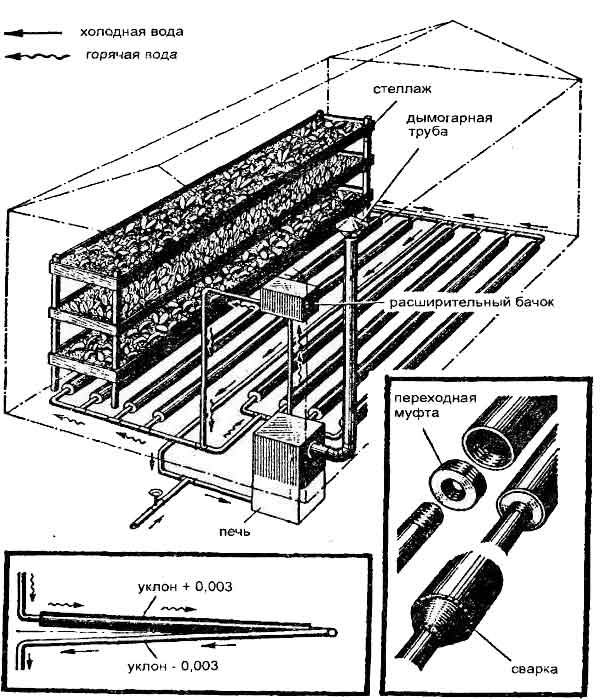

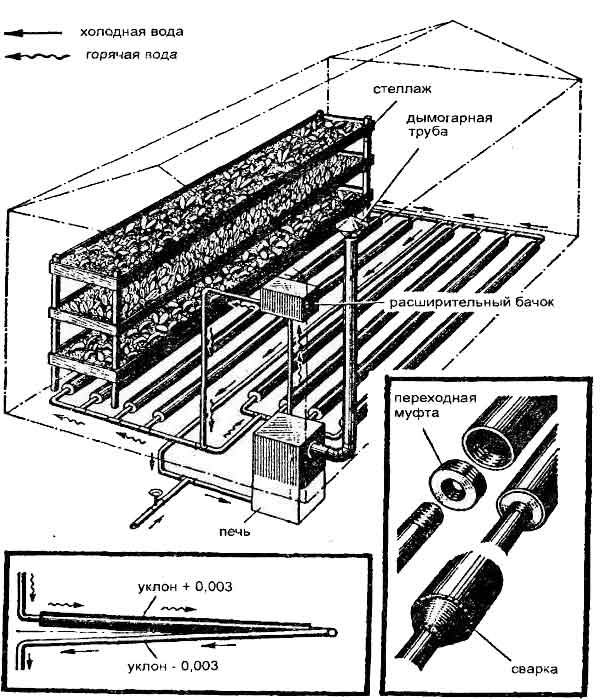

Greenhouse water heating scheme

Most often in modern greenhouses, water heating is used, which involves heating the grown plants in a cold period of time by means of hot water that circulates in pipes.

If the greenhouse is installed near a private house, then you can connect it to the building heating system. In this case, the heating scheme will make it possible to correctly correlate the heating system of the greenhouse with a similar system of a private house. However, in most cases, an independent system is built for the greenhouse.

Start of construction

With the differences between winter buildings and their main features, everything is clear. This is followed by the process of building the premises. It is quite obvious that construction starts with planning and drafting projects. Before you start erecting the main frame, laying the foundation and doing other work with your own efforts, you need to clearly understand what needs to be done. Modern technologies help to significantly simplify the construction process itself, but without drawing up the correct drawings, it's still nowhere. To better understand how to build a winter greenhouse in which the soil will constantly warm up, you need to study the main stages of construction:

- Design. When designing, it is very important to take into account all the main details and features of the building, starting with where it will be located and how the heating system will be arranged, ending with what crops will be grown inside. This will include the selection of the correct material for the construction of the building. Fortunately, modern technology provides building materials in a wide format.

- Laying the foundation. In this case, it is very important what material the construction is from. In any case, the foundation for growing plants in winter should be as reliable as possible.

- Heating works. It is quite obvious that the soil and shrubs of vegetables and fruits need good heating. That is why the heating is arranged even before the installation of the frame begins.

- Frame construction. Before erecting the walls, you need to install the frame.

- Walling. In this case, the work will directly depend on the material chosen.

The choice of material for manufacturing

In the process of drawing up a diagram, it is imperative to take into account the material that will be used for sheathing the frame.A winter greenhouse must be durable and airtight, so wood or metal is suitable from the materials. These materials are durable, so you can choose any. Wood is easy to work with, but metal is more reliable. The wood will not heat up at elevated temperatures.

The uprights must be strong and thick, otherwise they will not be able to support the weight of the building and the load from the snow on the roof.

Suitable for cladding materials:

- glass;

- polyethylene;

- polycarbonate.

If the choice fell on the film, then the frame must be sheathed in several layers. It is not recommended to use this material for the arrangement of the entire product.

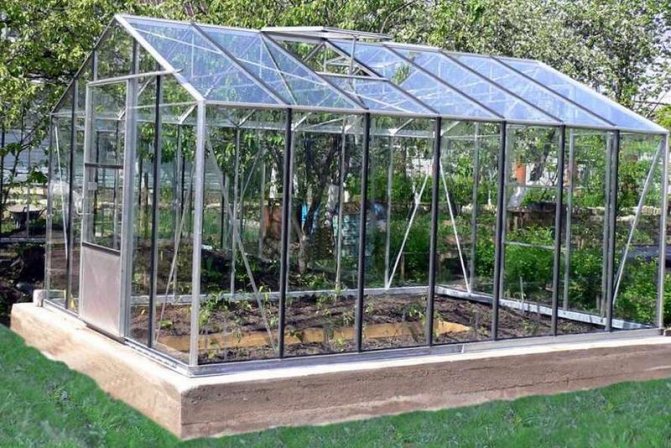

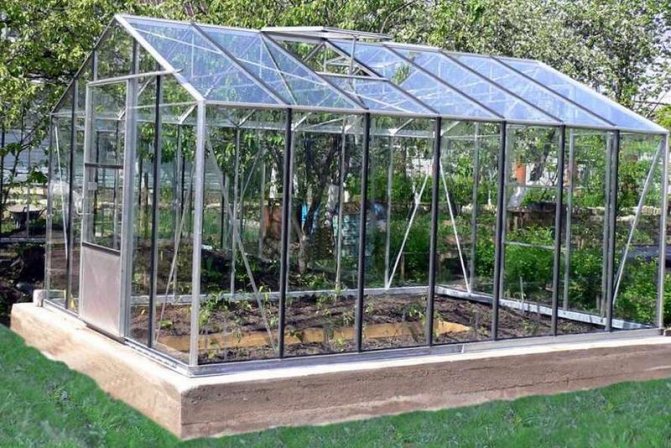

Glass-coated greenhouses are often produced.

Small glass greenhouse

The main advantages of this material:

- High level of transparency and durability. Unlike other coatings, the transparency of the glass remains unchanged during use. You will only need to clean the windows from dust and dirt from time to time.

- The material is environmentally friendly. During the heating process, it will not emit odors.

- Glass does not interact with other elements, therefore, in case of contact with chemicals or fertilizers, the glass will not change its properties.

The disadvantages include:

- Fragility. If, for any reason, the frame structure of the greenhouse changes its geometry, the glass cladding sheets will break.

- The large weight of the material, in connection with which the frame needs to be strengthened.

- The material is only suitable for stationary structures.

- Increased thermal conductivity. The air temperature in glassware quickly decreases in frost and at night.

- High material cost. This type of coverage is the most expensive.

Another type of coating is polyethylene.

Polyethylene coated construction

Main advantages:

- It can be used for the manufacture of structures of any complexity.

- Low cost.

- Ease of installation of the film.

The disadvantage is that the material is short-lived. A greenhouse that is covered with polyethylene is not able to withstand the weight of snow and strong winds. Therefore, summer residents need to dismantle the film from the frame structure in the winter. However, such actions have a positive effect on the condition of the soil.

Not so long ago, a new material has appeared on the market, which is called agrofibre.

Agrofibre coated construction

Unlike polyethylene, the material is durable and has a high level of transparency. Agrofibre is able to withstand heavy weight and strong gust of wind. The material is breathable, so the greenhouse does not need to be ventilated frequently. Another advantage is the lightness of the product. This makes it possible to move the greenhouse from place to place.

Another material is polycarbonate.

Polycarbonate coated product

This type of coating is quite popular, as it combines the advantages of the first two types. The material is a light, transparent plastic that has a high level of light transmission. Also, polycarbonate has the following advantages:

- The material is durable, it can withstand significant loads.

- Low thermal conductivity. This makes it possible to save heat inside the greenhouse for a long time.

During hot weather, the temperature inside the polycarbonate structure can exceed 60 ° C, so the product must be ventilated. It is recommended to provide vents in the building.

The choice of material must be based on the needs.

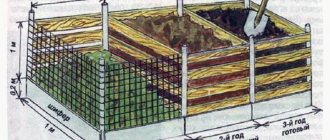

Calculation of the amount of material

It is impossible to make mistakes in the process of drawing up a drawing and calculating materials - everything must be accurate to 1 mm. Be sure to indicate the dimensions of the parts, even if they are repeated. An example of calculating the material for the manufacture of the frame is shown in the figure below:

An example of calculating the material for the frame

Next, you need to calculate the amount of material to cover. As an example, the calculation of polycarbonate will be performed, since it is used in most cases.

Installation of polycarbonate sheets

One standard sheet is 6 m long, and the thickness does not matter. The circumference of a standard greenhouse is also 6 m. If it is decided to make a greenhouse as a house, then the formula will be as follows: H x 2 + W, where H is the height of the structure, and W is the width.

Polycarbonate standard sizes

The leaf width is 2.1 m, which is 10 cm more than the standard span between greenhouse sections. This makes it possible to make a tight overlap of the sheets.

The end part of the structure is 3 m wide and 2.1 m high. To sheathe 2 ends, 1 polycarbonate sheet is required.

A sheet 6 m long must be cut into two parts to obtain 2 segments of 3 m each. The height of the segments will be 2.1 m. The elements completely repeat the dimensions of the pediment.

Accordingly, for a greenhouse with a length of 4 m, 3 sheets of material are needed. The first sheet is fixed at the end of the structure, and the remaining 2 sheets cover the product at the top. If you plan to make a structure 6 m long, then you need to purchase 4 sheets of material. For a greenhouse with a length of 8 m, 5 sheets of polycarbonate will be needed.

To make a greenhouse, the following elements will be needed:

- brush;

- paint;

- concrete mix for the preparation of mortar;

- roulette;

- building level;

- sand;

- electric drill;

- frame material;

- reinforcing mesh;

- nails;

- a hammer;

- coating material.

It is important to prepare tools and materials in advance so as not to stop the construction process.

Operating tips

To extend the life of your greenhouse, it is important to consider the following:

- To prevent heavy snow drifting, the structure should be placed at a distance of 1–2 m from buildings, fences and trees.

- After snowfalls, the greenhouse must be cleaned.

- To prevent the product from being blown off by the wind, metal pegs must be hammered in the corners of the building.

- Polycarbonate can be cleaned with a soft cloth dampened with water.

Greenhouses do not require much attention, however, periodic cleaning is recommended.

If you take a responsible approach to the issue of construction and follow the technology, then you can make a high-quality structure with your own hands, in which it will be possible to grow almost any plants.

Briefly about the main thing

So, we figured out the question of how to make a greenhouse with our own hands at home. As you can see, there are a lot of options, each of them has pros and cons. The only big advantage is self-erection, which does not require large costs. But it should be noted that not every greenhouse made independently has a high structural reliability. Professionals will make "candy" even from junk materials.

| A little more attention! I would like to hear in the comments about someone who already had the experience of building greenhouses with their own hands. What materials were used for this, how quickly the construction proceeded. And also about how effective such a greenhouse is.? |

Ratings 0

Read later