Repair and decoration

04.04.2018 Anastasia Prozheva

The smokehouse, which you make with your own hands, will become a useful accessory in the country.

When warm days come, I want to go to the dacha for more, but not only for weeding the beds, but also for relaxation.

Everyone loves to eat deliciously in nature, so a barbecue grill and a smokehouse in the country will become a real delight. All vacationers will be delighted!

Shish kebabs are quite a tasty dish, but already slightly fed up, which cannot be said about smoked fish.

We will talk about how to create a hot and cold smoked smokehouse, and also tell you how to make it from available tools.

Let's first find out the difference between cold and hot. It's simple. If you do not want to waste time preparing and assembling the structure, then turn your attention to a hot smokehouse.

In such a system, your fish or meat will be ready in 20 minutes.

In a cold smokehouse, food takes longer to cook, up to 5 days, and is a little more difficult to build.

Cold smoking process: features

The preservative properties of smoke have been known for a long time, but today it is not the most important thing that attracts a person to smoked products. Appetizing smell and unique taste - this is what is achieved when smoking meat, fish products, cheese and even fruits. In the process of cold smoking, the semi-finished product is saturated with aromatic substances that are released when burning wood raw materials. The best are sawdust of fruit trees - apple, pear, plum, apricot. From wild-growing alder, oak gives an excellent smell.

Cold smoking involves prolonged exposure to smoke with a temperature of 30-50 ° C for several days. In this mode, the products are uniformly saturated with aromatic substances and finally ripen.

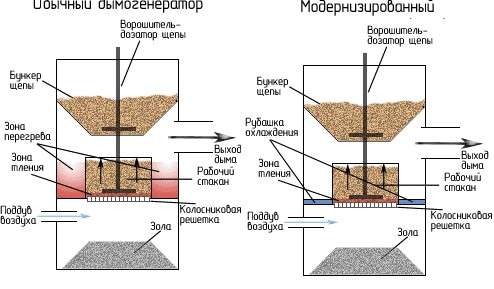

Stationary smokehouse: how to make, device

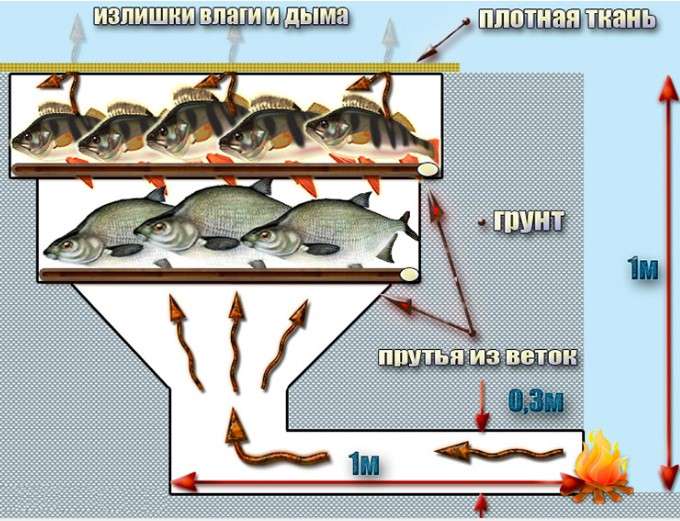

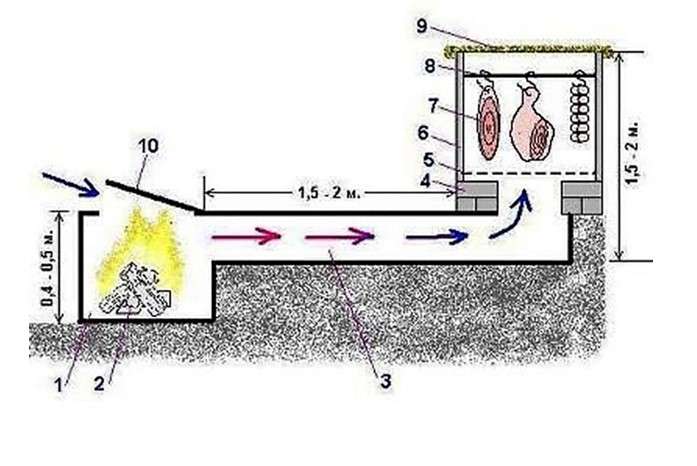

If the area and topography of the site permit, you can build a stationary cold-smoked smokehouse. The design is a smoking chamber connected to the firebox through a chimney. The area should have a slight slope to allow for natural smoke draft.

Camera

The chamber is made of wood or metal, equipped with a tight-fitting door and a pipe for exhausting smoke. You can lay out a clay brick smokehouse, setting the structure on a solid foundation.

The camera is placed in such a way that a height difference forms between it and the firebox. The pressure difference creates a natural draft that makes the smoke move upward.

Firebox

The firebox is made of heat-resistant masonry materials or metal. For periodic cleaning, it is equipped with an ash pan with a door. The smoke supply is regulated by a damper. As a rule, during ignition it is kept closed so as not to spoil the product with the first caustic combustion products.

Chimney design

The task of this important structural element is the deposition of tar and other carcinogenic substances contained in the smoke, as well as the reduction of the smoking temperature. The longer the chimney, the more efficiently the flue gases are burned and cleaned of combustion products.

The structure is a pipe 2 or more meters long. It is made of metal, and more often a tunnel is simply torn off in the ground. Soot and condensation settle on soil particles, and soil bacteria do an excellent job with carcinogenic waste.

Important. Unlike a metal surface, earth does not need to be cleaned. The smoke, passing through the channel, maintains the optimum temperature for smoking.

A natural slope is chosen on the site, a camera is installed at the top, a firebox is organized at the bottom. A groove is dug for the chimney, covered with sheets of metal and covered with earth. Do-it-yourself cold-smoked smokehouse is ready, you can carry out tests.

Chimney in the ground

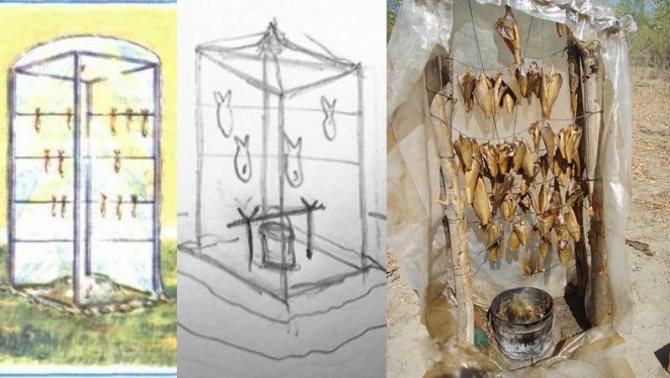

Material options for structures

Craftsmen were able to adapt almost everything to the needs of their country estates. The main thing is that the material is durable and not susceptible to combustion.

Popular types of finished products for the smoking chamber are:

- old boilers;

- metal buckets and boxes (100-200 liters, meter in diameter);

- brick, stone, etc.

Elements removed from old gas ovens can become grates and a pan. You can also create lattices of the required diameter with rods.

A cold do-it-yourself smokehouse for a summer residence is most often a full-fledged non-collapsible structure. The walls of the chamber can be made of cement (formwork technology) or brick.

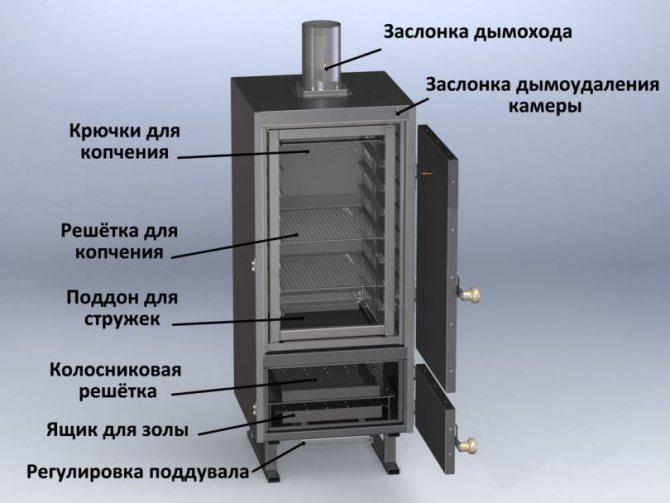

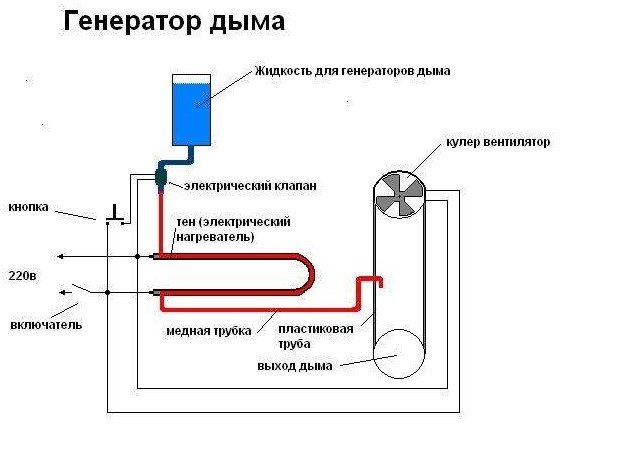

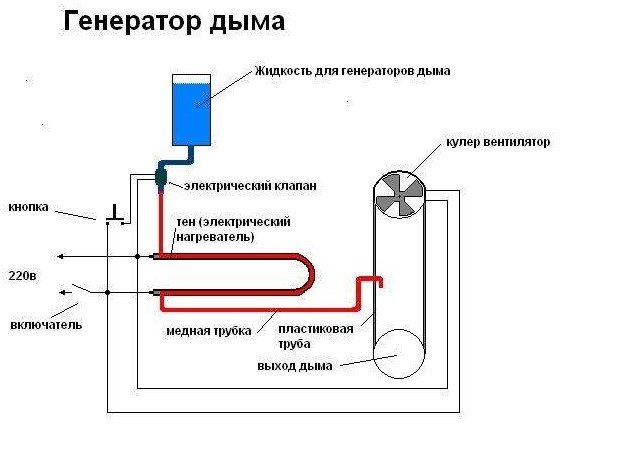

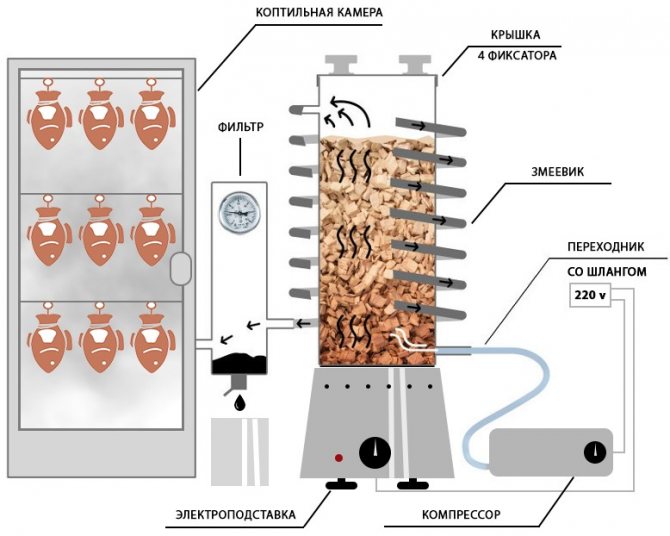

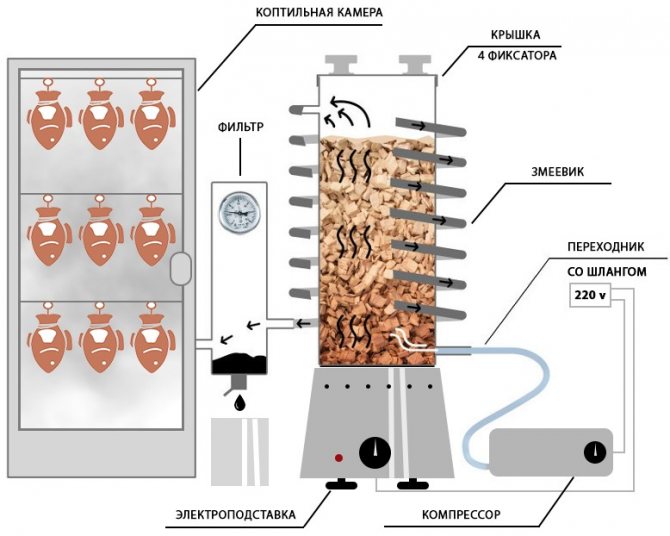

Homemade smoke generator for a smokehouse

If it is not possible to place a full-fledged firebox and a long smoke channel on the site, a smoke generator will come in handy to generate smoke. This compact device does not require much space, and the structure can be made from improvised means - an old fire extinguisher, a tin can, a large-diameter pipe section. You will also need thinner tubes for the chimney, a compressor (you can use an aquarium), a fitting, a container for collecting condensate.

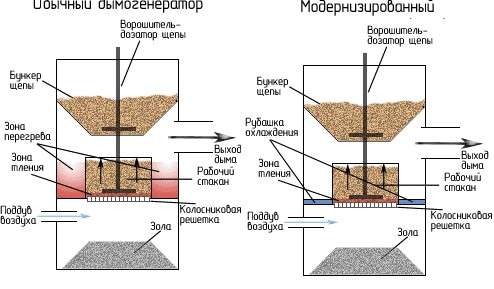

The simplest smoke generator consists of the elements:

- a body where chips smolder without air access;

- chimney;

- cooling system.

In the lower part of the tank there is a grate for chips, the space under it is used for ash accumulation. The air required for combustion is accessible through the lower opening with a damper.

Smoke generator device

Important. If you make the grate removable and equip the bottom of the smoke generator with a lid, it will be easier to clean the surfaces of ash and carbon deposits.

The device is connected to the chimney through a branch pipe. To regulate the supply of smoke, an ejector is provided in the form of a movable tube inserted into the branch pipe.

The sawdust is placed in a container and ignited through the bottom valve. The smoke, passing through the pipe, is partially cleared and fed into the smoking chamber. The movement of gases is activated by a compressor.

Video - DIY cold smoked smoke generator

The best professional smokehouses

Alto-Shaam 1767-SK / III

A versatile American-made smokehouse for the cost of a decent car. Designed for industrial cooking. In the kitchen of a restaurant, in catering points, this technique will emphasize the image of the institution. Completely minced, technically speaking, it can be cooked flawlessly with the utmost attention to detail.

The oven is equipped with the Halo Heat system (even heat distribution without using a fan), so that the air does not dry out the product, which significantly affects the quality of cooking. The use of a temperature probe with a range of 10 - 91 ° ensures the exact cooking time of the food. Gastronorm class GN1 / 1, The SureTemp system of keeping the temperature with the door open, meets the classic standards of gastronomy.With such a complex, there is no need to shift ready meals from place to place, looking for optimal conditions for preserving the appearance and taste. The oven will do everything by itself.

Antibacterial handles and a special non-magnetic stainless steel case will be a bonus. Natural for a smokehouse of this level is a led display, a computer program for saving recipes, digital control, a spacious chamber with 9 compartments, installation using fixed and rotary wheels with stops. The Alto-Shaam 1767-SK / III is every chef's dream.

TTM ISTOMA-EM

The Russian-made smokehouse is inferior to the class of gastronorm containers (GN2 / 1) of the previous model. But in terms of functionality, it is very pleasing with the presence of a similar system of uniform heat distribution, with the help of correctly located heating elements. The lack of a fan retains moisture without overdrying food. The issue of gastronorm containers, which are not included in the kit, is upsetting, but the reasonable price of a multifunctional unit makes a discount on this.

The device includes digital control, 8 memory modes, a program for storing cooked dishes, which turns on when the appropriate temperature regime is reached.

Cooking range up to 140 ', storage and probe temperature up to 95 °. The device for low-temperature cooking is convenient for its small dimensions, and an excellent roomy chamber up to 45 kg.

Bradley Smoker Digital 6 Rack BTDS108CE-EU

The size of a small refrigerator, this smoking machine is a budget option for representatives of its field of application.

It does not have a gastronomic capacity class, but it allows continuous operation up to 9 hours. Pressed briquettes of various flavors, tossed automatically - an innovative solution for smoking various types of meat, fish, cheese and vegetables.

The premium device has proven itself well at the professional level. The package includes:

- 6 grates, pallet;

- automatic regulation of time and temperature of smoking;

- electronic control and auto-off function;

- built-in thermometer;

- floor construction and secure fixation of the shelves.

A capacious modern-type smokehouse is attractive in price, has decent options for professional machines.

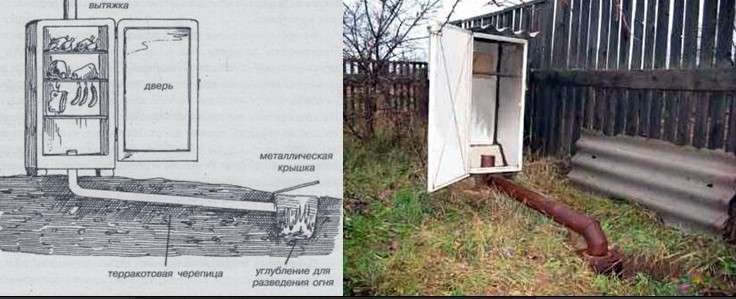

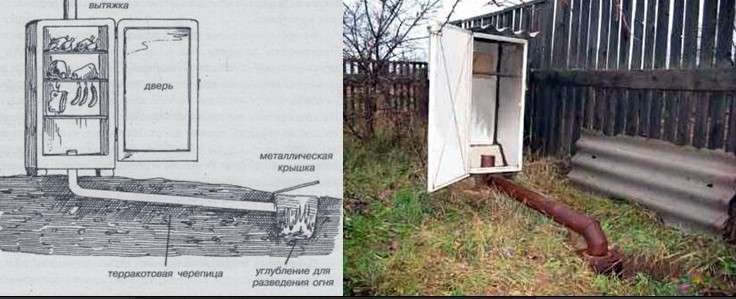

Smokehouse from the refrigerator: step by step instructions

An old household cooler, from which you have long wanted to get rid of, can get a "second life" and benefit the owner. This is an almost finished smoking chamber, which already has shelves for products and a tightly closing door.

It will not be difficult for a home craftsman to arrange a cold smoked smokehouse from the refrigerator. You will need:

- 2 steel pipes - one for the chimney, the other for the removal of smoke;

- firebox or smoke generator;

- bricks or blocks for the foundation;

- refrigerator, better than the Soviet model with a metal inner lining.

Newer generation refrigerators can also be used. It is recommended to remove the plastic insides, leaving only the metal. You will need hooks and grates to hang or lay out food. Old accessories will come in handy in Soviet coolers.

Stages of making a smokehouse from the refrigerator:

- Prepare the unit - drain the freon, remove the plastic sheathing, fix the devices for hanging the hooks, installing the gratings.

- To collect dripping fat, make a metal tray with legs.

- Cut a hole for the chimney in the bottom of the refrigerator. It should fit as tightly as possible.

- Make an outlet for the chimney in the upper part of the chamber.

- Lay out a foundation made of bricks or blocks on a flat area, or fix a solid support.

- Place the refrigerator on a plinth to create the required height difference.

- Connect the smokehouse with a pipe to a firebox or smoke generator.

- Carry out a test run.

To regulate the supply of smoke and the intensity of the draft, the chimney is equipped with dampers or valves. In a similar way, you can arrange a cold-smoked smokehouse from a barrel, steel box or large-diameter pipe.

Iron box according to the drawing

Step-by-step instructions on how to make a smokehouse are usually not required, everything is so simple. If you make it yourself, first sketch a drawing.

From metal of at least 3 mm, cut sheets with a grinder according to an approximate calculation: the length of the box is 60 mm, the width is 25 mm and the height is 7 mm.

It is better to make the lid with a curved rim, it must close hermetically. Assemble the structure by welding.

In the upper half of the smoking cabinet, weld the sides, on which the rods for the food hooks will be placed.

Another element is a drip tray. It is done taking into account the gaps for the passage of smoke (3-4 cm from the walls) and for wood chips (on the legs 5-6 cm from the bottom).

Place wood chips on the bottom of the chamber. Install the pallet. Place food in an iron box and cover it with a lid. Put the camera on fire. The process has started!

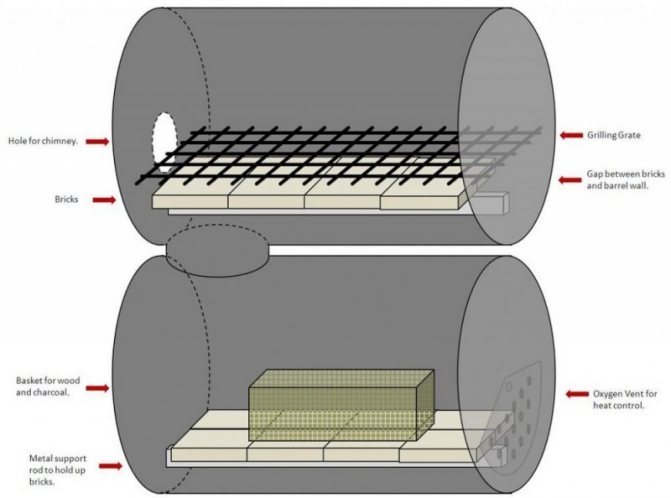

Smokehouse from a gas cylinder: step by step instructions

Surely the thrifty owner will find in the bins an old gas cylinder made of oxygen, carbon dioxide or propane. Possessing the skills of working with metal, you can build an economical version of a cold-smoked smokehouse from a gas cylinder.

Versatile gas cylinder design

You will need 2 gas cylinders - one larger, the other smaller, steel pipes with a diameter of 80-100 mm, handles for lids, grates, you can from a barbecue. To work you need a tool: a welding machine, a device for cutting metal. Pre-equip a place for a smokehouse and weld the supporting frame.

Oxygen or carbon dioxide containers are not hazardous. It is enough to bleed off the remaining gas. The propane cylinder must be prepared: after freeing from the explosive substance, unscrew the valve and fill it with water. If the metal flask is old, the valve can be carefully cut off with a hacksaw. To avoid sparks, water the cut with water.

The procedure for carrying out work on the manufacture of a smokehouse:

- Fill containers with water, let stand for 1-2 days. Drain the solution

- Cut out holes for the chimney at the ends of 2 cylinders.

- In a container intended for burning sawdust, cut a hole for the shutter (of any shape). Cut a hole in the smoking cylinder for the exhaust pipe.

- Make several cuts in the body under the cover, weld the hinges and then cut it off to the end. Install the handles.

- Make the cap of the second cylinder in the same way.

- Weld on the connecting and exhaust pipes. Install the flaps.

- Fasten the grate supports inside the smoking chamber.

- Equip the smokehouse with a thermometer, paint the structure in any color you wish.

Making a smokehouse from gas cylinders

This smokehouse is versatile. With some modifications, it can be used as a barbecue or brazier.

Solid buildings

There are owners of summer cottages and suburban areas who, with their own hands, try to do absolutely everything conscientiously. The following options are good for large suburban areas, where another small building will not be a hindrance, but a decoration.

Smokehouse made of bricks or foam blocks

The first stage is the search for a convenient site, preferably on a hill. After choosing a suitable drawing, they begin to calculate the material, then purchase:

- red brick or foam concrete blocks (better - hollow);

- silicate brick for the combustion chamber (an alternative is a purchased product built into the fireplace);

- the door for the firebox - made of steel or cast iron;

- window frame with frosted glass, door frame and leaf;

- sheet plywood, board (20x100 mm) or timber (60x60);

- grooved board (replacement - lining, its thickness - 10-12 mm);

- roofing material - profiled sheet, metal tiles;

- pipes: plastic for the roof and metal for the chimney (diameter - 80 and 120 mm, respectively);

- cement, sand, crushed stone.

Smokehouse foundation

After clearing the construction site, markings are made, the fertile layer is removed, its thickness is from 150 to 200 mm. Using the diagonals, they find the middle intended for the chimney pipe. Its role is played by a metal bucket with a round hole cut on the side for a metal chimney pipe. Starting from the center, dig a trench. If the section is horizontal, then an inclination of 20 ° is provided, it goes towards the combustion chamber.

At the same stage, a pipe is laid, one end of which is immediately inserted into the bucket. The trench is buried and proceeds to the construction of the formwork. It protrudes 250 mm above the surface. Then a pillow of sand and crushed stone is poured, each layer has a thickness of 70-90 mm, both are spilled, rammed. Half the mortar is poured, the distance from the upper edge of the formwork is 50 mm. Reinforcing mesh is laid on the set concrete, its cells are 50x50 mm. A screed is poured from above, into which liquid glass is added. It is leveled, focusing on the edges of the formwork, covered with foil and left to gain strength.

Firebox

The base for the firebox is made in the same way. The walls are erected in two layers. The outer wall is made of red brick, the inner one is made of heat-resistant silicate material. If a purchased combustion chamber is selected, it is buried in the ground. This method saves fuel, since the walls will cool more slowly.

Smokehouse construction

The walls are erected from slotted foam concrete blocks, characterized by low thermal conductivity. The laying starts from the corner, using a regular mortar or assembly glue intended for blocks. The verticality of the rows and the horizontalness are checked by the level, special attention is paid to the window and door openings.

Floor beams are laid on the structure, then the rafter system is mounted. If a soft roof acts as a roof, then the crate is made of solid plywood. When another material is purchased, the lathing step is calculated based on its dimensions.

The gables are sewn up with the same clapboard or board, a chimney is mounted in one of them to remove excess smoke. A window frame and a door frame are inserted into the openings, sealed with felt. The hole in the floor is covered with a removable fine mesh, which is designed to trap the remaining particles of soot. The inside of the smokehouse is equipped with mesh racks for cooking products.

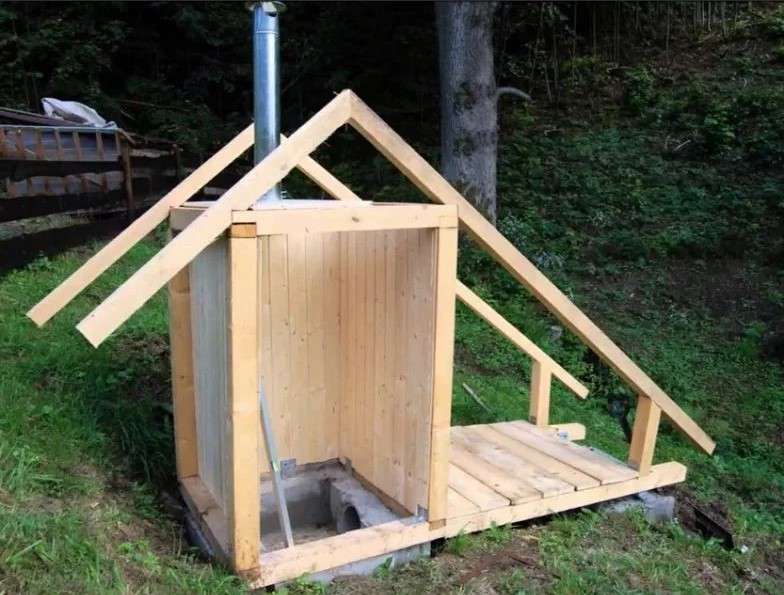

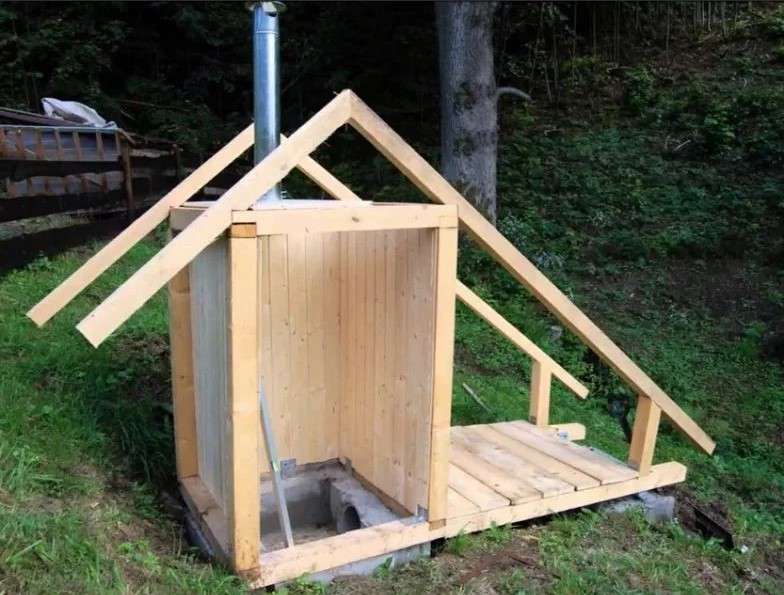

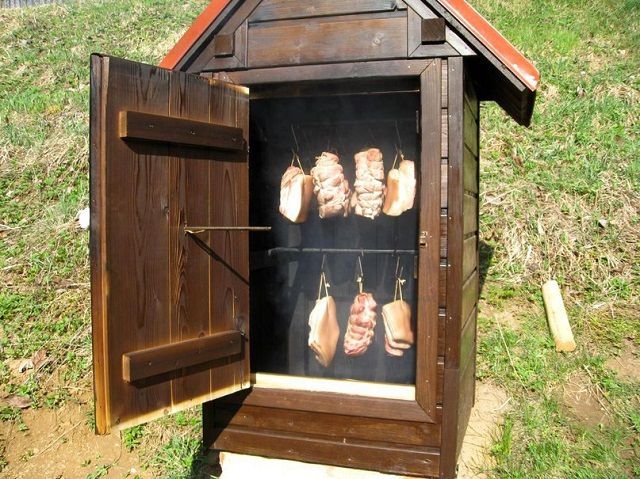

Traditional smokehouse made of wood

Bricks and blocks are not the only suitable materials. A small building made of environmentally friendly wood is the best "haven" for food. For this temporary storage, deciduous species are considered optimal - cherry, pear, oak, alder. You will need to collect the following materials:

- timber (50x50), board (10x100 mm);

- bricks: red for the base of the smokehouse, silicate - for the furnace walls;

- 2 pipes - refractory ceramic or metal (80 and 100 mm);

- sheet metal for flooring (3-4 mm);

- cement, sand, crushed stone;

- waterproofing material (tow).

Pits, trench, foundation

After marking, two small pits are dug, the distance between them is equal to the same recommended 2000-2500 mm. The first one, intended for a smokehouse, should be located on a hill. Its depth is 400 mm. The second, used for the foundation of the firebox, is deepened by 250 mm.

At the next stage, the grooves are connected by digging a trench. Further, in the pit under the smokehouse, they arrange a traditional pillow of sand and crushed stone, the layers are made the same thickness as in the case of a block structure. Pour half of the solution, lay the reinforcing mesh, but this time its cells are 30x30 mm. The remaining solution is distributed from above, the thickness of the screed is 40 mm. The foundation for the firebox is made in the same way.

A pipe of a smaller diameter is laid in the trench. From the side of the firebox, it should be 200 mm shorter than the trench.A solution is applied to the edge of it and a half-meter section of a pipe of a larger diameter is put on, it should go 150 mm onto the thin part of the chimney. This expansion in front of the smokehouse will allow the smoke to reach its optimum temperature.

Along the edges of this wide branch pipe that goes into the firebox, 2 bricks are installed. Then they move on to laying the walls in half a brick. The pipe is poured with a solution, a furnace door is mounted, which is additionally fastened with a wire laid in the seams of the masonry. A metal sheet is placed on top of the firebox.

Smokehouse

Checking the horizontality of the brick rows, they begin to build a base for the smokehouse. The total number of rows is 10, half of them rise above the ground. During work, the chimney is embedded. After the completion of the arrangement of the basement "floor", the trench is poured with a solution in such a layer that 80 mm remain free for backfilling with soil. After the mortar has set, the trench is filled up, tamped.

Frame

It is assembled from a bar, self-tapping screws are used as fasteners. After assembling the front and rear frames, they are connected with bars. Elements protruding beyond the perimeter by 50 mm are attached to the sides of the upper "strapping". The rafter system will be attached to them. For the construction of the roof ridge, vertical posts are fixed in the middle of the front and rear beams, they are also connected together with a long element extending 50 mm beyond the perimeter. In the middle of it, two boards are stuffed with such a length that the overhang is at least 150 mm.

Sheathing

Three sides of the semi-finished frame are tightly sheathed with boards in 2 layers: first, the elements are fastened vertically, then horizontally. Forming the doorway, it is made 5 mm larger than the door, ensuring its free entry even in the event of thermal expansion. Before sheathing the last side, crossbeams with cutouts for metal rods are attached to the inside on the sides. They will have hooks for food.

A hole for the chimney is drilled in the roof, its diameter is 5 mm. To ensure complete insulation of the gap, the cracks between the boards, glue and tow are used. The door is also made from 2 layers of boards. To control the temperature, a hole is made in it for a pin thermometer. The bottom is left open. The finished house, treated with a hydrophobic impregnation, is attached to the base with metal brackets. To ensure greater reliability, the roof of the smokehouse is covered with a light roofing material.

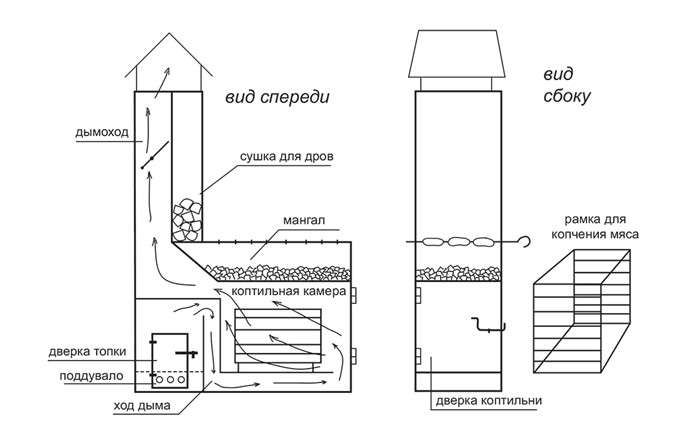

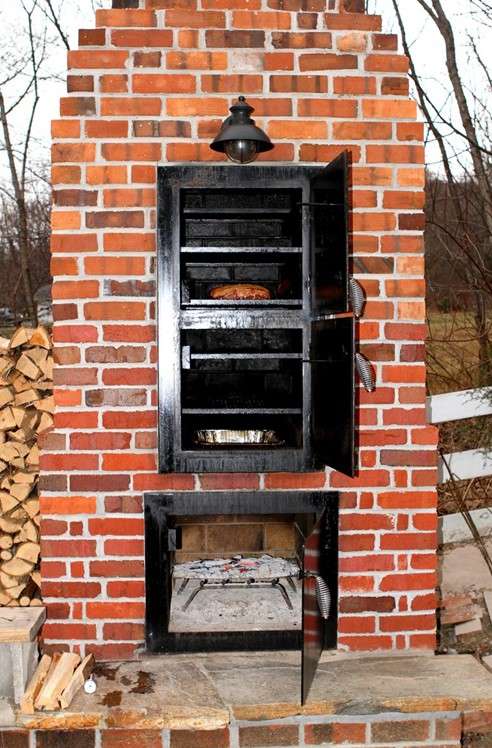

Smokehouse made of bricks

A cold smoked brick smokehouse is a solid, reliable construction, the construction of which requires the skills of a bricklayer. You can create a versatile option for hot smoking or grilling food.

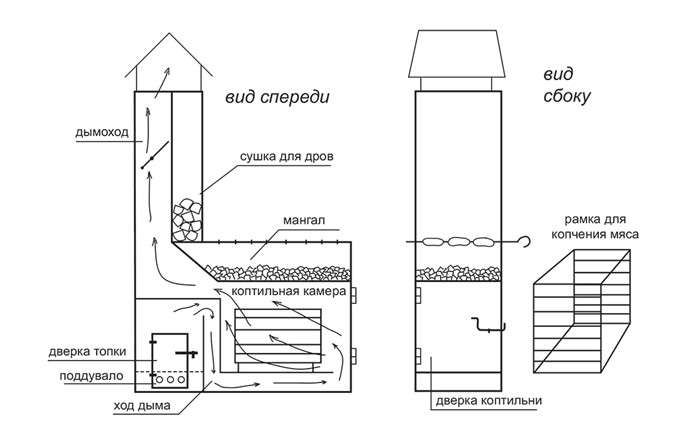

Before starting construction, they choose a place on the site and prepare the foundation. The peculiarity of a brick smokehouse is an internal chimney. Smoke from smoldering wood chips enters channels and shafts, cools and fills the smoking chamber. Only refractory materials are used for masonry.

A drawing of a cold smoked smokehouse made of bricks gives a visual representation of how you can use fire at once for 2 types of product processing - below is a smoking chamber, above is a brazier.

Materials and tools will be needed:

- refractory bricks, clay, water;

- doors, flaps, grates and hooks for food, grate, lid;

- shovel, bucket, trowel, building level, lace.

The laying is carried out orderly. Seams are tightly filled with mortar and trowelled to ensure airtightness. A chimney is formed inside the structure so that natural draft stimulates the movement of heated gases in a certain direction.

Brick smoker

In the upper part of the firebox there is a metal tray for heating sawdust. The smoke velocity and temperature are regulated by dampers fixed in the channel gaps. Around the ash pan in the masonry, a thermal insulation zone is arranged, where small river pebbles are poured.

Important. You can decorate the structure with various materials - facing tiles, bricks, plaster. Such a smokehouse will become a decoration and "highlight" of the site.

Do-it-yourself smokehouse in the country: rules of arrangement

Smokehouses for giving hot and cold smoking is a fire hazardous facility, which requires a location away from residential buildings, compost pits and living vegetation. Also, it is advisable to think over and eliminate dryness near such a structure, despite the fact that smoldering chips will occur in a certain depth.

For comfort, there should be enough space near the smokehouse to create a relaxation area for guests and carry out a number of manipulations by the chef. Usually they install:

- gazebos, benches with tables;

- tables with a special coating on which the finished product can be laid out.

It is also better to think about the escape of smoke in advance, especially with the cold method of processing food. The convenience of maintaining the optimum temperature is ensured by the installation of metal thermometers inside the structure, as well as direct access to the firebox for throwing chips in.

Home smoked products are valuable because they are environmentally friendly. No artificial colors are used in their manufacture, and the smoke is obtained from chips of carefully selected wood species. But another important point is the maximum naturalness of the materials inside the smokehouse. For example, for the pallet and trellis, you can use a vine (willow rods), knocked into denser structures or with the presence of parallel holes. The thickness of the rods should vary by about 9 mm. The chimney and brickwork may be processed from clay with sand.

Operating tips

A cold smoked smokehouse at home is convenient and practical. But when using the device, you must follow the safety rules:

- avoid contact with flammable materials;

- do not touch hot surfaces with an unprotected hand;

- do not install the structure on an unstable base;

- do not allow water to enter the wiring and the compressor of the smoke generator;

- do not use sawdust with traces of paint, varnish, impregnation;

- do not leave small children unattended;

- do not install a smokehouse near a residential building to prevent smoke;

- control the temperature to prevent overheating;

- do not handle expired products.

Smokehouse at a safe distance from home

The chimney and the chamber must be periodically cleaned of carbon deposits, the grates and hooks must be washed with detergents. It is advisable to leave a non-working smokehouse slightly ajar for ventilation.

Important. Ready smoked meats are kept in a draft for 1-2 days before use to remove the remaining smoke.

Preparation of food

Lard, game, fish or meat are prepared in a certain way before smoking, since the products are processed with smoke at a low temperature. Smoking has preservative properties and prolongs the shelf life, but this does not happen immediately, but gradually. So that during a long process the delicacy does not deteriorate, preliminary salting is required.

Salting fish before smoking

Cut the bacon into 7-15 cm pieces, soak in a marinade of water, salt and spices. The brine must be concentrated for a raw egg to float. Keep in the refrigerator. After 3-5 days, take out the bacon, dry it and put it in a smokehouse for further processing for 1-2 days at a temperature of 30 ° C.

The fish must first be gutted and washed. Place in a bowl, sprinkle with plenty of salt. After 2-3 days, remove, rinse thoroughly in running water and soak for 1-2 days. Then the fish should be allowed to weather well in a draft to a semi-moist state. The time depends on the size and structure of the pulp. Smoke for 2 days at a temperature of 30-40 ° C.

The meat is salted dry, wet or in a combination. Keep in the refrigerator under pressure from 5-7 days, up to 2-3 weeks.Then the semi-finished product is dried for about 5 days in a draft and sent to smoke for 2-3 days.

Smoking technology

Cold smoking technology is quite simple, but at the same time requires special attention and careful preparation. You need to choose high-quality products, pickle or salt them, cut them, dry them. Particular attention should be paid to the choice of wood chips, because the final result will largely depend on this.

Choice of wood chips

As a rule, hardwood chips are chosen for cold smoking. You can also use fruit trees. The ideal option would be to add a small amount of juniper twigs to the chips along with berries, grapes or currants. Berries will give smoked meats a special taste and aroma.

Do not use coniferous and birch wood chips together with bark. These types of wood contain a lot of resin, which will have an extremely negative effect on the taste and appearance of the finished smoked meats.

Preliminary preparation of products

Before starting cold smoking, it is necessary to properly prepare the products, cut and marinate them. Otherwise, the smoked meats will not be tasty and aromatic enough. In no case should this stage be skipped.

Wet Ambassador

Wet ambassador involves preliminary preparation of the marinade. It uses water, salt, black pepper, bay leaves, as well as your favorite spices and herbs. The marinade is brought to a boil and then cooled to room temperature. After that, the finished products must be poured with marinade and sent to marinate in the refrigerator for a certain time.

Dry ambassador

This variant of the ambassador is considered to be the simplest. Portions of semi-finished products are evenly rubbed with a large amount of salt on all sides. You can also add a little black pepper and spices to the curing mixture to taste. Future smoked meats are laid out in a container that does not oxidize and sent to the refrigerator.

Combined Ambassador

In this situation, dry and wet salting is combined. At first, for some time, future delicacies should be marinated exclusively in a curing mixture. Then they are poured with marinade, pressed down by oppression and sent to the refrigerator for a few more hours. This method is the most laborious, but it allows you to get incredibly tasty and aromatic smoked meats.

Smoking meat

Cold smoked meat is especially tasty. It is necessary to purchase high-quality and fresh raw materials, cut them into portions and marinate in one of the above ways. As a rule, preparation takes from 12 hours to several days, depending on the chosen recipe. Then the semi-finished products are thoroughly washed in order to remove excess salt and are hung out in the fresh air for a while. In just a few hours, the meat has time to dry out. Then the future smoked meats are placed in the smokehouse and the smoke treatment process is started. It will take 2 days and up to a week to cook cold smoked meat.

Smoking fish

Only high quality and fresh carcasses are suitable for cold smoking fish. The fish is pre-cut into portions, salted for several hours to several days. Then it is thoroughly washed and dried in the open air. It is best to smoke the fish in a suspended state, which will allow it to be saturated with smoke evenly from all sides.

Cold smoked poultry

The principle of cold smoking poultry is not at all different from the preparation of a ball in a smokehouse. The only difference is that it takes much less time to process with cold smoke. The smoked meats will be ready in just a couple of days of continuous processing.

Firewood preparation

The taste and smell of the final product largely depends on the composition of the chips.A variety of ready-made raw materials for smoking are sold in stores, but you can prepare firewood yourself.

If work is being carried out in the garden on the formation of crowns and pruning of fruit trees, there is no need to rush to throw away the branches and twigs. After good drying, they are crushed and used for their intended purpose. Smoked meats from apple-tree shavings acquire a particularly appetizing aroma.

Chips must be dry and clean

The grapevine for smoking and making barbecue is often used in the Caucasus. The smoke from the smoldering vine gives the delicacy a delicate fruity flavor and golden color. In summer cottages and household plots of the more northern zone, this thermophilic culture is also quite common. Pruning annually leaves a lot of unnecessary branches that can be dried, shredded and mixed with sawdust.

To add spicy notes, twigs of juniper, mountain ash, acacia are added to the chips. They not only enrich the product with a bright aroma, but also have an additional bactericidal effect.

Important. Do not use coniferous wood chips. It imparts bitterness to the smoke due to its high resin content.