More advanced summer residents use a homemade lawn mower that they make with their own hands. By the way, it is quite possible to make it from improvised means. The main thing is to collect the necessary parts in a heap.

Electric lawn mower application

An electric or gasoline lawn mower can hardly be called an essential item.

And yet, it helps to tidy the lawn, which is not just a well-groomed plot that attracts the eyes of neighbors, but also speaks of the status of its owner. Finding an electric lawn mower that suits your preferences is not a problem in our time.

However, such a pleasure will cost a lot, therefore, for many, a do-it-yourself electric lawn mower is a more attractive option. To assemble the much-needed electric home-made structure, you need to spend only a few evenings, easily finding a medium-power motor on the farm: from a chainsaw, a vacuum cleaner, a drill, even a washing machine.

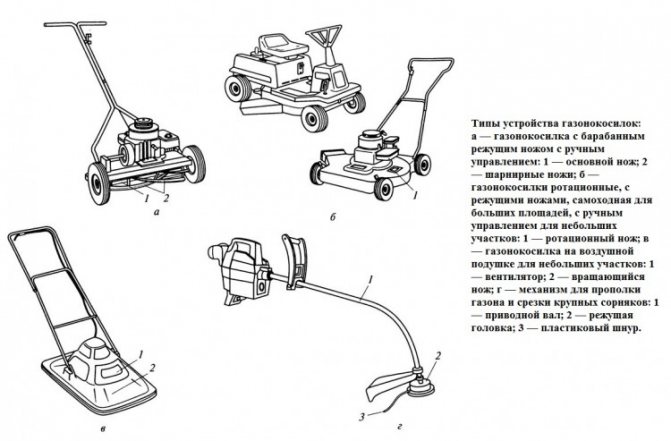

Which lawn mower is better to buy: choose the type and model

With the arrival of summer, the owners of personal plots and cottages are thinking about how to tidy up their lawn - an important component of landscape design. And the best solution to the problem would be to buy a lawn mower. However, making the right choice with all the variety of models and brands is not so easy. In our review, we will talk about how to choose a lawn mower based on your individual needs and give a rating of lawn mowers in three different categories of this lawn and park equipment.

Using a chainsaw

The petrol-powered mower will be an excellent help on the farm. But first, you need to prepare tools and spare parts. Domestic models "Druzhba" and "Ural" are suitable for solving the problem. Additionally, you have to purchase:

- metal corner;

- 2 wheels;

- pipe cut;

- metal knives;

- metal plate;

- rotary discs;

- bearing;

- accessories.

As for the corner, it will be used to make a rigid frame. But a metal plate is needed for the site. Wheels can not be purchased, but borrowed from a stroller or trolley. The pipe cut must have a diameter within 5 cm. To mate with the pipe you need a gear. A homemade mower will be performed using fittings, namely:

- nuts;

- bolts;

- rivets;

- staples.

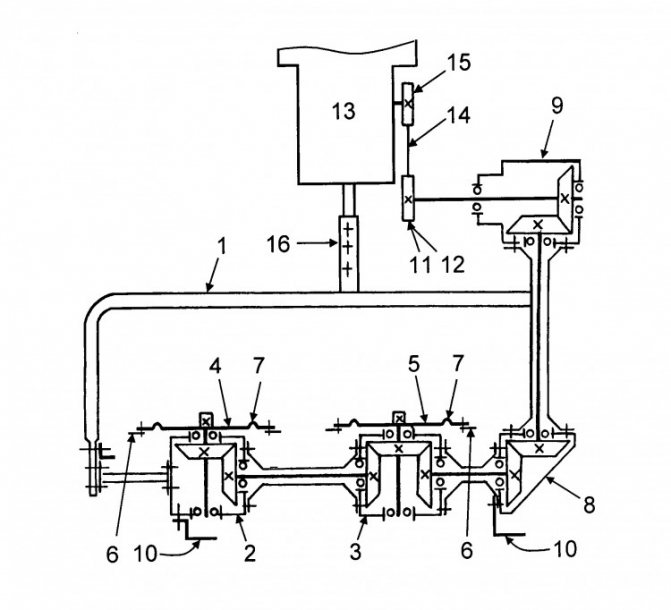

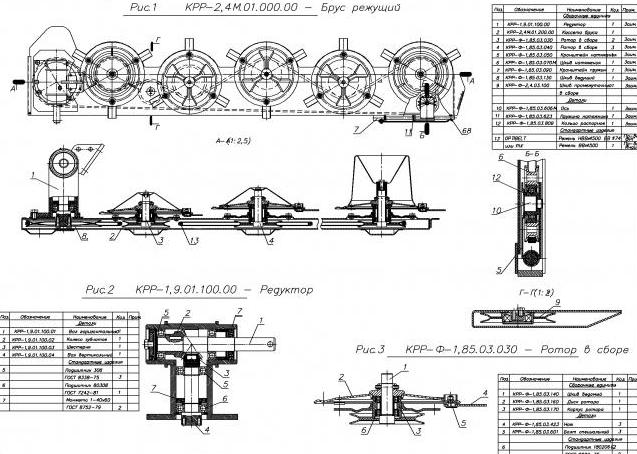

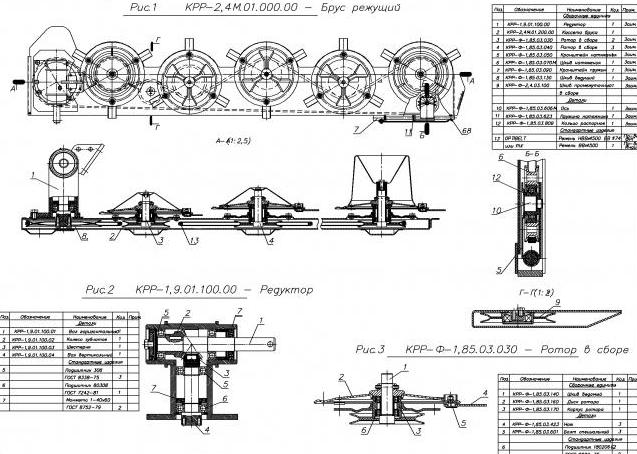

How to make a rotary mower

A do-it-yourself rotary mower, which is useful in a summer cottage, is done as follows. A home-made rotary mower-cultivator of rotary action is made from the rear axle of a VAZ. For work you need:

- disks;

- reducer chain;

- metal cutters;

- shank;

- opener.

The following tools should be prepared:

- screwdriver;

- Bulgarian;

- drill;

- drill;

- screws;

- nuts;

- pliers.

An inexpensive home-made rotary-type mower is made like this. It is necessary to make holes on the discs. Then attach the tine to the opener and the knives to the tine.The knife and the shank should be at a distance from each other at a distance of the thickness of the first. The cutting element must rotate 360º. To create the axles of the knives, carbon steel with a diameter of 8 mm is needed. It is necessary to bring the axle to the stop by means of the disc. This is how rotary mowers are made for a tractor or for a walk-behind tractor with their own hands. Moving on to the next homemade product.

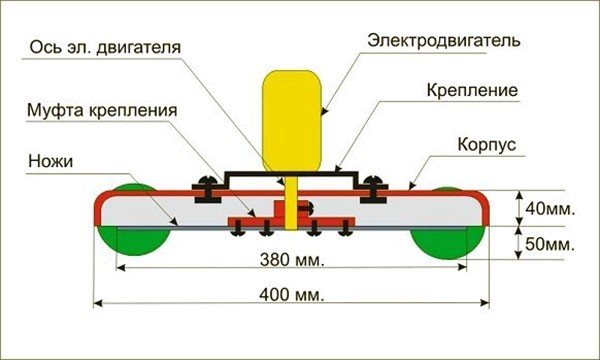

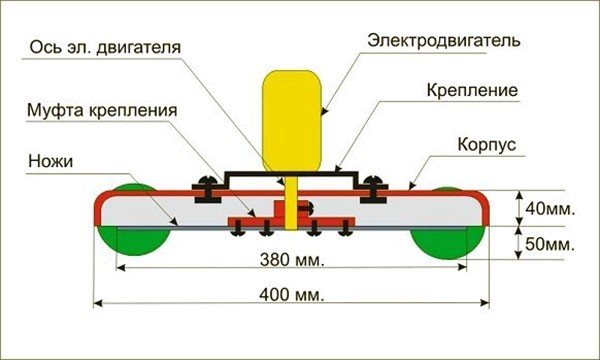

What does an electric lawn mower consist of?

Of course, the most important part of it, including the homemade electric lawn mower, is the motor. Motors are capable of converting energy into mechanical energy of any other kind.

They are divided into primary ones, which convert energy resources into mechanical energy, and secondary ones, which convert energy, which is generated by other sources:

- chemical energy of fuel - internal combustion engine;

- fuel, i.e. when fuel is burned - a piston engine;

- igniting a compressed air mixture in the cylinders - gasoline;

- working due to the ignition of fuel under pressure - diesel, which is distinguished by its low cost and the possibility of long-term operation;

- gas, functioning by supplying heat (with a constant volume);

- electric.

When choosing a motor, you need to know that the quality of the haircut directly depends on the engine speed: the higher this value, the higher the quality. That is, it depends on the linear speed, which is in direct proportion to the speed of the cutters: the higher it is, the greater the grip.

It is known from practice that the best option is a home-made electric design with the following characteristics:

- motor power 1 kW;

- the number of revolutions - 1.5 thousand rpm;

- capture - 50 cm. A less powerful engine will also cut weeds - 500 kW (1500 rpm). But he will do it worse. At the same time, knives dull faster with low-power motors.

The electric mower has a convenient handle and knives. Since the homemade design is powered from the mains, a long cord is needed. To work conveniently, you cannot do without wheels, which are attached to the lower part of the frame, which holds all the parts together.

For convenience, a protective cover is used.

Prophylaxis

It is also very important to monitor the condition of the carburetor. It needs to be cleaned periodically. Its casing is dismantled. Screws are loosened. It is removable from the plastic. Garbage (if any) is removed from it. There is a cover under the cover. The carburetor is concentrated under it. He's filming. First, the fuel hose is disconnected (through it, the fuel tank and carburetor communicate). Fuel may leak from it. You need to be more careful. The carburetor is removed, held in place by a pair of bolts. Next comes the analysis.

Unscrew the bolt holding the fuel cover. When cleaning, special products are needed. The WD-40 will do just fine. It is necessary to thoroughly clean the fuel channels of this mechanism. A thin copper wire is required. Cleaning begins with the fuel compartment. The mechanism is abundantly soaked. The carburetor is left alone for a short time. This process is repeated several times. The channels are cleaned with copper wire. Let's admit them blowing under pressure. After these operations, the mechanism is assembled in the reverse algorithm.

Clogged compartments and ducts are the most common cause of engine problems. Constant monitoring of their cleanliness will significantly extend the life of the engine and make it work more efficiently.

Where to find parts

For an electric mower, a motor with a power of 500 W from outdated household appliances, which is in working order, is suitable. It can be a vacuum cleaner, drill, chainsaw, grinder or washing machine.

The more engine power (ideally 1 kW), the more the homemade device will work at lower speeds. Consequently, the knives will dull less.

In addition, the capture area depends on the power of the motor, i.e.the area cut with a knife at a time.

The size of the homemade electric mower and the diameter of the knife, which is also considered one of the main parts, the quality of which affects the result and service life, depends on the selected engine.

Lawn mower based on an old washing machine

As you know, Soviet "washers" were stamped from strong metal. Their engines are optimally matched to the performance and power of the lawnmower you have in mind.

The superior steel body serves as a defensive skirt and guide as the grass is pushed to the side.

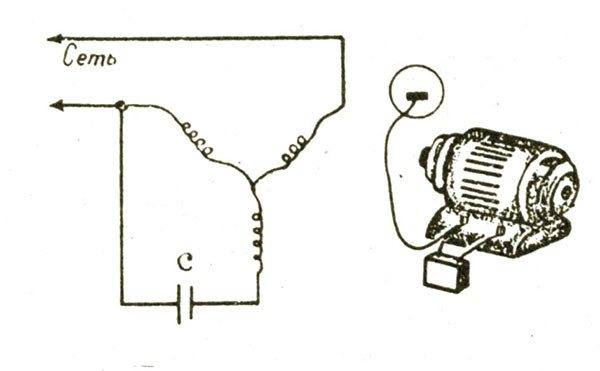

It also uses two pulleys and a belt that transmits impulse from the engine to the knife mechanism. The motor is mounted on a platform and is only connected for one phase.

Such a unit will work in the area near the house, since it is tied to the network with an electric cord. To make the device more mobile, a special coil wire is used - an extension cord with a section corresponding to the power of the motor. Its minimum length is 40 m.

Spare parts cost

Before you start manufacturing the equipment described in the article, you need to ask what the cost of spare parts is, because some of them you will have to purchase. For example, a bearing sleeve that fits the Virax mower will cost the consumer 50 rubles. But you can buy a drum casing for 1200 rubles.

The rear hinge sleeve costs a penny - 40 rubles. a piece. Such is the price for distance protection. When considering spare parts for a mower, you should also pay attention to the drive shaft. Its cost is 500 rubles. The knife holder will cost you 250 rubles. The drum sleeve costs 2400 rubles. A belt pulley equipped with a latch will cost 4000 rubles.

The main parameters for choosing a lawn mower (data are relevant for the summer of 2017)

- Bevel width from 44-47 cm

- Weight up to 30 kg

- 3 in one, or better 4 in one (mandatory mulching, grass catcher, side / rear discharge)

- Self-propelled (rear wheel drive)

- Collecting bag 65-70 l (better soft)

- Motor power 2.5-3.5 hp

- Motor Briggs & Stratton

or watch the video (this is the only video in which it is normally told, but a lot of what I write about in the video is not told)

Gasoline, Electric or Battery? - definitely gasoline

At first I wanted to buy on a battery (we don't even consider an electric one with a wire, as it is very inconvenient). And it seems there are even options with autonomy up to 50 minutes of work (greenworks brand). 50 minutes is cool, as the average running time of a mower on battery is 20 minutes (and 10-15 minutes in mulching mode).

But after the price tag was announced to me from 40 thousand rubles. despite the fact that the battery costs about 10,000 and its resource is about 4-5 years, I gave up this venture.

I write the criteria in descending order according to my personal opinion. I do not consider powerful lawn mowers for areas over 2000 m2 (more than 20 acres)

The middle grass mowing area has an area

10-15 acres (I do not take into account summer residents, they mow with Chinese electric trimmers from Leroy or OBI and constantly lament that the wire is interfering)

So, based on my experience and communication with sellers and repairmen from service centers

- Weight

- Volume and type of grass catcher

- Bevel width

- Bevel height

- Functionality 3 in one (mowing, collecting, mulching)

- Self-propelled (ease of control)

- Storage compactness

- Power

- Ease of Service (Maintainability)

- Which manufacturer to choose

- 8 parameters for choosing a lawn mower

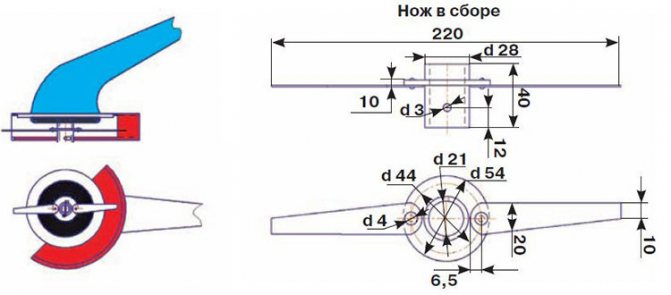

What should be a homemade knife?

So that the knife does not need to be sharpened often, it is recommended to make it from high quality steel. They sharpen it to protect the motor shaft from damage, unevenly: sharpen the edges without touching the place where it adjoins the shaft, since the grass is practically not cut off in this place, but only wrapped around the knife.

Strips of tool steel with a width of 20-50mm and a thickness of 2-3mm are a suitable starting material for the manufacture of this part. Although a thicker knife is stronger, a thinner blade cuts weeds better.

The knife can be:

- a strip, the ends of which are sharpened and carry knives;

- consist of two knives, fixed in relation to each other at an angle of 180 degrees. They can be located straight or tilted.

In the first version, the knife length and grip width are equal - 30-50 cm. The length of the knives used in the second case does not exceed 50-80 cm. There are several ways of attaching the knives - using one bolt or two. More reliable, of course, is the second option. But, knives fixed with one bolt, can, when an obstacle occurs, fold without deforming or breaking.

In shape, it can be straight, curved (like branded electrical devices), curly (in the shape of a trapezoid). The part sharpened at both ends can be solid with a hole in the center for a screw.

The knife can be a composite structure, i.e. a sharply sharpened piece attached to the steel strip by welding or bolts. The most unusual will be a knife, which is a sharpened one-piece disc.

How to change the oil

For everyone who is periodically faced with mowing weeds, a lawn mower is an indispensable item. A simple device, however, sometimes requires maintenance, which includes changing the oil used to cool the mechanism, which allows the motor to operate at high rpm.

In addition, the oil protects parts of an electrical device stored at low temperatures.

The frequency of oil change is determined by the technical condition of the engine. In new devices, it is necessary to change the oil in the lawn mowers immediately after the break-in is completed, i.e. after 5-6 hours of continuous operation.

In the future, the replacement is made after another 5-10 hours. This prevents debris from accumulating in the motor. In an engine that is not new, the period between oil changes increases to 25-50 hours, which corresponds to 2-3 months.

It is possible to determine that the oil needs to be replaced by its color: as soon as a black tint appears, it is necessary to replace it so that the motor does not jam.

The entire process for replacing fluid is divided into stages:

- draining old oil;

- turning the electric lawn mower with the drain hole down;

- installation of the device in a horizontal position;

- pouring new oil through the neck up to the mark on the crankcase.

What kind of oil to put in the mower depends on the ambient temperature in which the garden tool is used. It is correct to use SAE-30 fluid if it is 5-30 degrees outside. An oil with a viscosity of 10W-30 is suitable for the off-season, and the 5W-30 series is most preferred in winter.

We cannot ignore Synthetic 5W-30 - a reliable tool that ensures the operation of the device at low negative temperatures.

Sharpening the blades

After preliminary straightening of the cutting part, you can start sharpening the lawn mower knife. Care must be taken to remove all chips, nicks, and deformed areas from the cutting edge and to ensure that the cutting edge slope is one flat plane. For this, it is recommended to work slowly and carefully.

The emery bar is the simplest and most affordable tool when sharpening lawn mower knives. It is recommended to use a grinding stone with a grit of 400 to 600 grit. Before use, the bar is kept in a soapy solution for 10-15 minutes, and during the sharpening process, the grinding surface is periodically moistened with water or a weak solution of edible salt.

When sharpening lawn mower knives, it is important to keep the stone in the same position, otherwise there is a risk of knocking and making the cutting edge uneven.It is important to ensure that an equal amount of metal is removed along the entire length of the knife, otherwise the balance will be displayed incorrectly. An exception to the rule is a lawn mower knife with four blades: due to the number of working elements, such parts are insensitive to balance imbalances.

Recommendations for use

- The knife will be less likely to dull if it is made of high quality steel.

- To keep the motor shaft intact, the knife needs to be sharpened unevenly. It should be sharp to the edge. The place with which it touches the shaft should not be touched, since the grass near the area where the knife and the shaft are attached is rather poorly cut, but only is imposed on the knife.

- You can arrange the regulation of the handle in length.

- The knife can be protected from contact with the ground. To do this, you need to make safety bumpers.

- For cut grass, you can provide a special collection.

- Before turning on the unit, you need to carefully check its condition: the sharpness of the knives, the reliability of the fasteners, the free movement of the wheels.

- Before work, clean the working area: remove debris, stones, pieces of wood. They can damage the machine or injure the mower.

- Drive children and animals out of the work area.

- When working, push the machine away from you.

- When there is a pause in operation, disconnect the unit from the power supply by pulling out the plug from the socket.

- Do not work in rain or wet surfaces.

- Clean or repair the unit only after its mechanism has completely cooled down.

- Experts recommend making a blocking button in the device. It will act if the knife is damaged or jammed. This diagram is:

Handle of a homemade electric mower

The handle can be made of any length and shape - at the discretion of the master. In practice, they often use a chassis from a baby stroller, which solves three problems at once, since it simultaneously serves as a frame, handle and wheels. If there is no stroller, it is made from pipes or cuttings of gardening tools.

Whatever the handle is made of, the main thing is to choose it correctly according to the height of the person who uses the lawn mower. Its optimal length is about 90 cm.

At the final stage, connect the cord and install a net to protect against cut weeds. The mesh is attached over the mower. This completes the assembly of the lawn mower, and you can proceed to testing it.

Selection and installation of handles

The handle of a grass mower is most often made specially, using a welding machine and metal pipes.

However, it is quite possible to use ready-made elements, dismantled from an old stroller or garden cart.

In the selection process, attention must be paid to the lightness, durability and reliability of such elements.

The self-assembly of the lawn mower can be greatly facilitated by using the entire frame removed from the trolley or stroller.

The handle of a grass mower is usually made of a folding type, which makes it easier to transport and store such a unit.

Wheels

The wheels provide ease of operation, allowing the mower to move easily. It has already been said that the best choice of wheels is a baby stroller. But, wheels from a vacuum cleaner, a large children's car are also suitable. As a last resort, they are carved from wood.

Video: Homemade lawn mower

The diameter of the wheels for a self-made electric mower is selected based on the fact that the distance between the ground and the knife is 5-6 cm. This height is optimal in terms of aesthetics and quality of lawn mowing. At a higher cut of the grass, the latter "breaks" and the lawn becomes uneven. If you reduce this value, it is dangerous to work due to uneven ground.

There is no consensus on the required number of wheels. It can be 2,3 or 4 wheels.

Two wheels of the design give maneuverability, allow you to cut grass even in hard-to-reach places. And finding them of the same diameter is easier than 3 or 4.

We recommend:

- Do-it-yourself lawn mower from a washing machine

- How to choose an electric lawn mower

- Self repair of electric lawn mowers

In the latter case, it is possible to very precisely set the distance to the ground of the knives. In a three-wheeled device, a pair of wheels are located on the side of the handle, so that the structure can be easily lifted from the front and made a U-turn by pressing on the handle.

It is more difficult to work with small wheels, which is why it is recommended to choose a larger diameter.

Selection and installation of wheels

The wheels for a home-made lawn mower should not be too large, but the height of such elements to the central part of the unit is usually at least 100 mm, which ensures optimal placement of the cutters and comfortable movement of the device over the treated area.

Wheels that are too small, including furniture ones, are not capable of supporting the significant weight of metal structures for mowing grass.

The mower wheels are mounted on bearings or plastic bushings

The correct choice of wheels is especially important when making a mechanical-type mower on your own, due to the lack of an engine. The movement of mechanical units is carried out by means of pushing forces applied by the operator. When choosing wheel diameters, the size of the mower and the speed of the cutters are taken into account, and the tread pattern should prevent slipping on the grassy surface.

In the process of movement of a lawn mower of any type, rotary movements are carried out with knives, which is accompanied by cutting off the lawn grass.

Alteration of a screwdriver into a grinder

If the angle grinder is broken or is missing at all, then it can be temporarily replaced with a cordless or mains electric screwdriver. In this case, there are various options for redoing. The easiest way is to use ready-made or homemade nozzles or adapters. An example of an adapter is shown in the photo below. One end of it is fixed in the chuck, and the disk clings to the other.

Another option that allows you to convert a drill-screwdriver into a grinder is to use a special type of attachment equipped with a gearbox. When implementing the method, the power tool is disassembled, its gearbox is dismantled, and a nozzle is installed instead. After transformations, you will get a tool similar in appearance to an angle grinder.

It should be borne in mind that such a special attachment is expensive and the modification work takes a lot of time.

Homemade nozzles are made from studs of a suitable diameter, nuts and washers. They are even used with cordless electric screwdrivers.

Engine speed and dependence

The quality of the grass scythe is determined precisely by the number of turns. The classic scheme is that the higher this number, the smoother the lawn will turn out. So, but not so: the salt is that a level lawn is not determined by the speed of the knives, but rather the linear speed of the cutting edge.

For the latter value, the gripping diameter of the knife is very important.

The large grip, which is more than forty centimeters, ensures a high-quality mowing of the grass. But here you need to remember about the relationship between power and diameter. The point here is the resistance that occurs with a wide cutting surface.

Frame fabrication

The frame is made of thick plywood or metal. To make the homemade design safe and less likely to need repairs, you also need a protective casing. The best material for making it is metal.

The size of this part depends on the length of the knife. But, rarely, when the maximum width is made more than 60 cm. Taking a sheet of metal not less than 3 mm thick, cut out a square 50x50 cm (or 60x60 cm). The hole for the engine must be made in the center (at the intersection of the square diagonals).

The flanged motor is mounted from below directly to a homemade frame. To securely fasten the motor with the ears, additional fasteners are required, which must be welded to the frame.

The metal frame is more reliable and less prone to deformation. But, if there is no metal, you can make it from plywood or board.

A cover is required to prevent weeds and other debris from entering the motor shaft. The simplest option would be to use a tin can as it. If there is a desire to make the casing, you can make a more aesthetic look. The high cover also protects the electrical mechanism.

Device

All electric lawn mowers are designed in the same way. They have a platform for mounting a motor, the shaft of which is parallel to the ground. A knife (or two) is fixed on the shaft of the electrical device, with which weeds are mowed. For a good mowing, the speed of the electric cutting tool must be high.

For convenience, the platform itself is equipped with four wheels and a handle with elements attached to it that control the engine. It is designed to push the device forward and operate the electric mower.

The wheel attachment can be rigid and swivel. In the first case, you will have to lift two wheels when cornering. Swivel ones involve the use of less physical force.

In addition, they "spoil" the lawn less. Therefore, if flowers are planted on the lawn, there are swings, gazebos, etc., then it is recommended to use swivel wheels. Electric lawn mowers with such wheels are convenient for caring for areas under bushes and trees.

The engine is enclosed by a housing, which at the same time protects the operator from injury by accidental objects when operating the electric lawn mower. The material used for its manufacture is more often plastic and less often metal. As you can see, the device of an electric lawn mower is quite simple.

Assembly guide

If you want to make a mower using a chainsaw, then a pipe will need to be inserted into the bearing groove. There should be a gear inside. Lugs are welded to one of the ends of the pipe, the length of each of which will be 2 cm. Holes are drilled into them. You can make knives from a saw blade.

The strip is cut into the required number of equal strips. Rivets and bolts will fix the knives on the rotor disc. A metal bar can also act as a basis. Choosing the rotor diameter, you may prefer the traditional value, which is 39 cm. It will be the best assistant for anyone who decides to make a mower with his own hands, a drawing of such a device. It needs to be studied first.

From a metal corner, you can make a rigid frame, the parameters of which will be equal to the dimensions of a gasoline tool. A rectangular stand will be located inside the structure, the body rests on it. The joints must be made at right angles, and they must be made as rigid as possible.

Specifications

Having learned about the main types of lawn mowers, let's move on to a detailed acquaintance with their characteristics.

Lawn mower engine power, trimmer... In gasoline models, it is measured in horsepower, in electric models - in watts (1 hp = 735 W). The power range of the mowers is from 2 to 7.5 HP. For a plot of 6 acres, a petrol mower with a capacity of 1-1.2 hp is enough. (or a trimmer with a power of 800-1000 W). For mowing an area starting from 6 acres, units with a capacity of at least 2 hp and over 1000 W are required, respectively.

Mowing width. The higher this indicator, the fewer visits you need to make in order to mow the grass on a certain "strip" of the lawn.The optimal minimum for all areas for mowers on wheels is 45 cm, for trimmers - 25 cm.

Lawn mower deck. The deck is the supporting structure of the mower. With its shape, it helps to create an air flow and draw the grass into the interior of the mower. It also protects the operator from scattering grass residues. The deeper the deck, the better - the high sidewalls suck in the grass better. The ideal deck material is aluminum, which is lightweight, durable and strong. Plastic or steel decks have disadvantages (brittleness and susceptibility to corrosion, respectively).

Assembling the lawn mower

The assembly will require the following tools:

- welding machine;

- hacksaw for metal.

The finished casing is put on the shaft, then a sharpened knife is installed, securing the entire mechanism with a bolt. When this is done, wheels are attached to the frame, for which corners with pre-drilled holes must be welded to it.

The size of the wheels is selected in such a way that the knife passes over the ground at a height of 5-7 cm. At a lower location, there is a high probability of its contact with the ground, and at a higher one - crushing of weeds (not cutting).

What is mulching?

Lawn mowers cut grass in three main ways. The first is with the grass scattering back or to the sides. With this method, you will have to manually collect the grass from the lawn after the end of mowing. The second method is by placing the cut grass in a grass catcher, which you then need to clean yourself. And the third known method is mulching. When using it, the grass is crushed into a fine gruel and evenly scattered over the lawn, naturally fertilizing it. The advantage of this mowing is that the lawn covered with grass requires 40% less water for irrigation. However, not everyone likes the look of decaying plant debris. This, as they say, is a matter of taste.

Methods of work

Attachments for the handle and wheels should be welded to the frame. Hooks made of a metal rod will act as a support. In the next step, you can start installing the wheels. The chainsaw must be prepared, for this, the blades and the chain are removed from it, and then attached to the frame.

The device of the mower will provide for a protective platform in the form of a plate, which is prepared taking into account the correspondence of the contour to the body. A pipe is connected to the sprocket of the tool, which will have a working part of the equipment. Now you can start fixing the lever, handle and cable system, the latter of which will be responsible for turning the equipment on and off.

Choosing a lawn mower depending on the type of site

Let's summarize briefly.

- For a small and uneven area (4-6 acres), it is worth choosing a low-power electric trimmer. For example such as Eco GT-800L... It has a power of 800 W, has a cutting width of 35 cm, and has a fishing line as a cutting base. This unit weighs only 5.5 kg, the handle is comfortable, folds and is adjustable in height.

A large and uneven area (more than 6-8 acres) involves the use of a gasoline trimmer (brushcutters). Makita DBC 340 is a classic representative of a powerful brushcutter with an engine power of 2.2 hp. The engine displacement is 25 cc. The cutting elements are a knife and a fishing line, weight - 6.7 kg.

For a small, level and well-groomed area, a small wheeled electric mower is suitable. Model ZigZag EM 107 PH assumes the processing of areas of about 300 sq.m. The motor power is 1000 W. The mowing width is 35 cm. There is an adjustment of the mowing height and a rigid 27 liter grass catcher.

Electric mower from a drill

The frame is made in a curved shape. An example would be a homemade drill device, where a wide knife is attached instead of a drill. The drill is fixed on the frame handle.

The advantages of such a device include:

- no connection of the power cord, since the drill mechanism is used;

- the ability to cut grass near curbs and under trees.

It is not difficult to think of attaching a drill to the frame of a drill, but in terms of operating time and reliability, a home-made lawn mower based on it will be inferior at times to asynchronous motors, which are more often used for these purposes. Therefore, to care for large areas, they prefer the latter.

A drill is more suitable if you need to assemble a homemade trimmer.

How to choose a lawn mower for a summer residence

I collected information on forums and communicated with service centers and experts. I have collected everything here on one page, read and decide which lawn mower is best for you.

If you are lazy to read the entire page, here is the main thing to pay attention to.

I bought myself an AL-KO 46BR lawn mower worth 23,000 rubles, and I am absolutely satisfied with it.

Here is my lawn (how it was and how it became after 3 months)

How to determine the design features

A homemade mower can be rotary or segmental. The first type is the most popular and convenient in terms of performance. The working part of the equipment is a disc with floating rotating knives. Such settings are effective when you have to cut tall grass.

Movable knives deal with weeds. If you want to make a device from a chainsaw, then there is no reason to doubt, because the unit is perfect for re-equipment, in addition, you can transform it back. The petrol-powered mower will have knives, the material for which will be saw blades for wood. You can also use metal sharpened teeth.

How to choose an inexpensive and reliable lawn mower?

Adding an article to a new collection

The growth of grass on a personal plot is as inevitable as the change of seasons. If you want your lawn's hair to be as smooth as a rookie soldier's, you need a lawn mower.

In England, they joke that the perfect lawn can only appear after 200 years of continuous mowing. It hardly makes sense to wait so long, because with high-quality processing, it is already able to give a thick, bright and juicy coating the next season. Lawn mowers and trimmers will be your assistants in this matter. We will tell you what characteristics you should pay attention to, how many types of lawn mowers there are, which model is right for you and how to make it last longer.

Advantages and disadvantages of homemade lawn mower designs

They depend on the parts used for the assembly.

The main benefits include:

- environmental friendliness;

- cheapness (since you can use any household appliance);

- noiselessness (if an asynchronous motor is used).

Low noise is undoubtedly an important indicator, but given that any lawn mower, including a home-made one, makes manual work incredibly easier, it can be endured, so any other motor will do.

It is not advised to use the motor from a vacuum cleaner due to its rapid overheating. If there is no other, you can use that too. And fight overheating with the help of the correct casing made of metal mesh or having holes for air circulation.

The disadvantage of a homemade tool is the knife, which is not adjustable in height. But, if you have certain skills, you can fix it.

Vacuum cleaner

The necessary details here are:

- wheels of large diameters (create a smooth free movement);

- welding equipment;

- two steel sheets;

- saw / hacksaw.

Instructions for implementation:

- A platform is cut from the indicated sheets. It will house the engine from an old vacuum cleaner. The motor will concentrate with its shaft in the lower area. The engine also needs a protective cover. The thickness of the casing is 1.2 mm. It makes holes 4 mm larger than the shaft. The engine is positioned 3-4 cm from the ground, otherwise the unit will break during operation.

- A metal disc is placed on the motor shaft.

- The knife is prepared in several copies. A disc with a diameter of 3.8 - 4 cm is cut out of a metal sheet. The disc is put on the shaft disc end and welded to it.

Working width - max. 25 cm.

Pros of a homemade model:

- Cost savings.

- Environmental friendliness.

Minuses:

- The height of the knife cannot be controlled.

- Weak level of security.

- High probability of breakage.

It is not difficult to eliminate these disadvantages. It is important to have the necessary skills here.

Safety during operation

Safety precautions must be observed both when working with a factory lawn mower and a home-made one, since they have knives and the tool works from the electrical network.

It is important to check before connecting the instrument to the network:

- reliable fastening of bolts;

- sharpness of knives;

- free wheeling.

On the site to be processed, it is advisable to collect everything that can cause breakdown of a homemade structure and injury to the person who controls it: wooden blocks, stones, debris. There should be no children and pets in the area.

Outcomes

The power lawnmower is therefore an excellent tool for maintaining a relatively small area. Unlike its gasoline and electric counterparts, such an installation does not emit harmful substances, does not shock, produces much less noise, is sold at a significantly more affordable cost and has a number of other advantages.

You have read the information about the principle of operation of the power lawn mower, studied the rating of the most popular models and received useful recommendations for working with such installations. Follow the advice you receive and your lawn will always remain beautiful and well-groomed.

Good luck!