Every summer resident wants to have a beautiful green lawn on his site with perfect beds and luxurious flower beds. To get the desired result, you need not only desire, time and effort, but also a special technique. To keep the soil in good condition, many people prefer the grass mulching procedure, as this method does not require much investment and is quite effective. Immediately after mowing, the grass is laid on the lawn, and in the process of decomposition it releases the substances necessary for fertilization. To speed up the decomposition process, it is recommended to chop the grass and thick stems. A herb chopper is required for this procedure.

The main units of the garden shredder

In order to independently assemble a grass and branch shredder (shredder) at home, you must first understand the device of the mechanism, as well as the principle of its operation. This will help to properly assemble the equipment and, if necessary, make changes to its design.

A home-made unit designed for chopping mowed grass and sawn branches up to several centimeters thick has the following main structural units:

- engine;

- knives mounted on the working shaft;

- frame (usually metal);

- protective cover;

- a box designed to receive cut vegetation;

- starting system.

The equipment itself can be made in a stationary or mobile form. To create the latter option, you will additionally need wheels, as well as a handle. To make a frame, use metal corners or ready-made frames from workbenches. Boxes for recycled vegetation are made of plastic buckets, tin, bags. The protective cover around the knives must be thick and strong enough so that it does not quickly wear out from the action of the milled vegetation.

Which garden shredder to choose: overview and criteria for garden grass and branch shredders

Any owner of a garden plot or a private house has, to one degree or another, faced the problem of recycling plant waste. This issue is especially acute with the beginning of spring work and at the end of the season, in the fall. We have to come up with all sorts of ways to get rid of the accumulated cut branches, dry grass and leaves, from dead shrubs and the remaining tops, etc.

Garden shredder which one to choose

To help solve this complex of problems, and even get tangible benefits from this, a special type of garden equipment will help, namely, a garden shredder. Not so long ago, few people heard about such a useful unit, but today it becomes, often, an indispensable assistant for the gardener. True, this type of technique is still a novelty for most, and many do not even imagine what possibilities it has and from which side to approach it when choosing it. We will help our readers - an article about which garden shredder to choose, what to pay special attention to, what basic rules to follow during operation.

Learn how to make a DIY compost pit with instructions on how to create it in our new article.

What is a garden shredder for?

In any household with a garden or vegetable garden, a considerable amount of various plant waste inevitably accumulates. Starting from early spring, with the cleaning of the territory, pruning of trees, shrubs or vines, the yard or the useful area of the site begins to become littered with heaps, getting rid of which sometimes becomes a very difficult task. In the summer, weeding will be added to this during the period of mass growth of weeds, cutting bushes, removing parasitic shoots, collecting fruits fallen from trees, etc. In the fall, it is no easier at all, since the care of trees and bushes, the removal of tops from vegetable beds and fallen leaves, and much more are again on the agenda.

Such deposits and the appearance of the site spoil and interfere with work on it.

As a rule, such heaps of vegetation waste are extremely compact, take up a lot of space, are very difficult to load and transport, and spoil a cozy area with their appearance. What to do with them?

Large branches can still be cut for firewood. To some extent, part of the problem is solved by the presence of a compost pit, but it is extremely unprofitable to lay large fragments in it, since the pit will quickly overflow, and dense branches will decompose for a very long time.

It is quite expensive to take out such mountains of garbage, since the rent of transport, and the loading of waste, and removal - all this costs a lot of money.

It would seem that the simplest way out is to burn. But here, too, not everything is so simple:

- Firstly, this is not a completely simple event from the point of view of compliance with fire safety.

- Secondly, in many regions, especially in urban areas, categorical bans on the incineration of plant waste are legislatively introduced, and you can run into big trouble.

- And thirdly, this is a completely meaningless, unjustified event. Any plant feeds on "vital juices" from the earth, taking from it the substances necessary for growth and development. It turns out that the incineration of plant waste is a purposeful destruction of the most valuable biological product, and ultimately - an unmeasured depletion of fertile soil on the site. Isn't it better, instead of buying some fertilizers on the side, to use the available reserves?

All this "baggage" of problems is solved by purchasing one garden installation - a shredder (there are often foreign language synonyms - a garden shredder or a chipper). This unit is able to quickly grind large plant waste into a small mass, with the disposal of which there will be no special problems.

It is much easier to figure out where to put the shredded waste

- Such shredded waste will no longer clutter up the compost pits, and the process of their biological decay will be much faster.

- Shredded wood becomes an excellent mulching material and good fertilizer.

- It is much easier even to simply take out the crushed waste from your territory. They can be packed into bags and loaded into the trunk of your own car.

- Wood chips can even be used as fuel - in particular, they are processed into pellets.

Convenient type of heating oil - pellets

This granular fuel is produced from various types of plant waste. Under certain conditions, you can make equipment and master homemade do-it-yourself pellet production - about this in a special publication of our portal.

Thus, such a unit has a great variety of advantages, and it can increasingly be seen in the "arsenal" of zealous owners.

How a garden shredder works

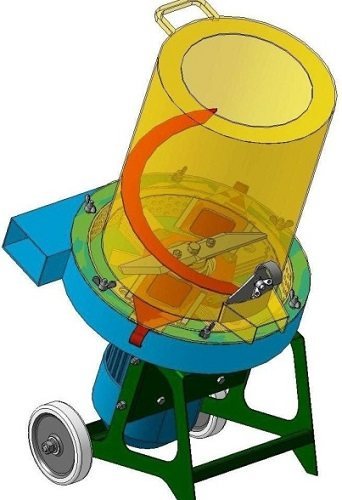

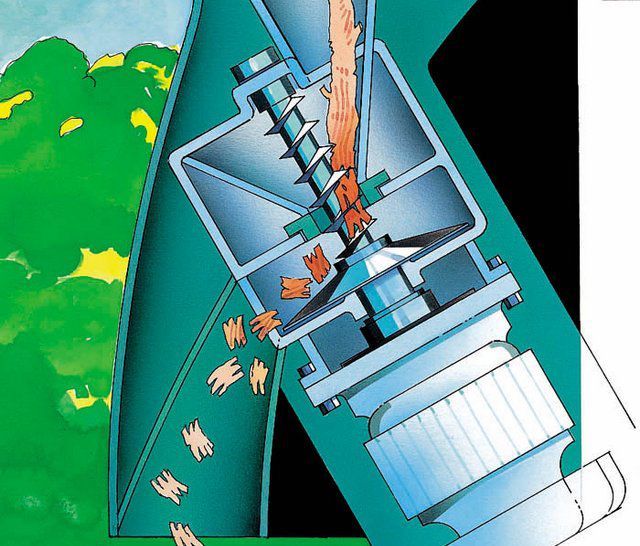

Schematic diagram of the device of a garden shredder

Despite a wide variety of models of garden shredders, differing in size and operational capabilities, they are all assembled approximately according to the same basic diagram, somewhat reminiscent of the device of a food processor.

The variety of models is large, but the schematic diagram of the device is about the same

- It is a robust housing made of metal, polymer, or a combination of both. The body can be installed on a frame, which is very often equipped with a wheel drive - for the convenience of transporting the unit across the site.

- The operation of the grinder is ensured by the operation of a power drive - it can be an electric motor or an internal combustion engine.

- The drive through a power train is connected with a cutting (chopping) mechanism of one type or another.

- In the upper part of the shredder, there is always a loading hopper, usually with a funnel-shaped expansion for the convenience of feeding plant waste for shredding.

- The ground mass can enter the receiving hopper, into a soft container (bag), or be thrown onto the ground. Some powerful models are equipped with spreaders with the ability to adjust the height and direction of distribution of the crushed waste.

Power point

Garden shredders can be equipped with either an electric drive or an internal combustion engine. Each of the options has its own pros and cons.

- The electric drive is more typical of small household appliances of low and medium power, up to 2.6 kW. These shredders are quite capable of handling the moderate amounts of waste from a typical garden plot.

Small Electric Garden Shredder

They usually do not differ in large dimensions and weight, therefore they can be easily moved to the place of work. Their maintenance is minimized, preparation for work, start-up and operation do not require any special skills.

At the same time, their "attachment" to the electrical network may be an inconvenience. For example, in a suburban area of a large area, a long cable will be required, which is not always convenient, and sometimes simply impossible, due to the banal lack of a connection point. There are certain restrictions in the work and according to the weather criterion - simply for reasons of electrical safety.

- Gasoline-powered units attract with their autonomy - they can be used in any "field" conditions.

Garden shredder with gasoline engine.

As a rule, they are equipped with a two-stroke gasoline engine. Such shredders can already perform more voluminous work, process large enough plant waste, up to the trunks of small trees.

Prices and range of ELITECH garden waste shredders

Garden waste shredders ELITECH

The operation of a gasoline engine will already require the owners of certain skills in handling it. So, for refueling, you need to prepare a fuel mixture, you will have to regularly monitor the condition of the candles, gasoline and air filters, and carry out preventive work. However, too complex internal combustion engines are not installed on equipment of this class, and all this can be quickly learned.

- Diesel engines are usually installed on professional equipment. Such drives are capable of operating for a long time without pauses, they keep well at low revs, and do not require a complex ignition system.

Powerful diesel engine garden shredder

But in domestic conditions, such grinders are practically not used, simply because of their high cost, large size and difficulty with independent transportation across the site.

However, the type of drive is not always the determining factor in the “professionalism” of the shredder. So, you can purchase a compact household model with a gasoline two-stroke engine, and at the same time there are stationary or mobile units of the professional class, equipped with a powerful three-phase electric motor.

Powerful shredder with three-phase electric drive

Garden Shredder Shredder

The torque from the power drive is transmitted to the working tool - the cutting or shredding mechanism of the shredder. And he, in turn, can be arranged in different ways. So, there are three main types:

- The knife mechanism is usually a disc with radially spaced knives made of tool steel. The rapid rotation of the blade disc cuts the supplied crop waste into small pieces.

Scheme of operation of a chopper with a knife mechanism

The advantages of such a scheme are its simplicity, low price, and ease of maintenance. Well-sharpened knives are able to process foliage, grass, stems of bushes and annual plants, usually up to 20 ÷ 25 mm thick. A mechanism of this type does an excellent job with freshly cut shoots and branches, but when processing hard, dried plant waste, the blades can become dull (even a large fruit stone, for example, from a plum or a peach, can cause a problem). Some shredders use special knives with multiple angled blades. The upper knife cuts the supplied branches into smaller pieces, while the lower one already provides the final chopping.

Cutting mechanism with two pairs of knives of different configurations.

For a knife-type mechanism, a forced supply of material for processing is required - it will not "pull" the branches into itself. For this, special pushers are used.

In service, such shredders are the simplest, that is, removing the knife for sharpening or replacing it with a new one is usually a completely simple procedure. Most household appliances have just such a mechanism.

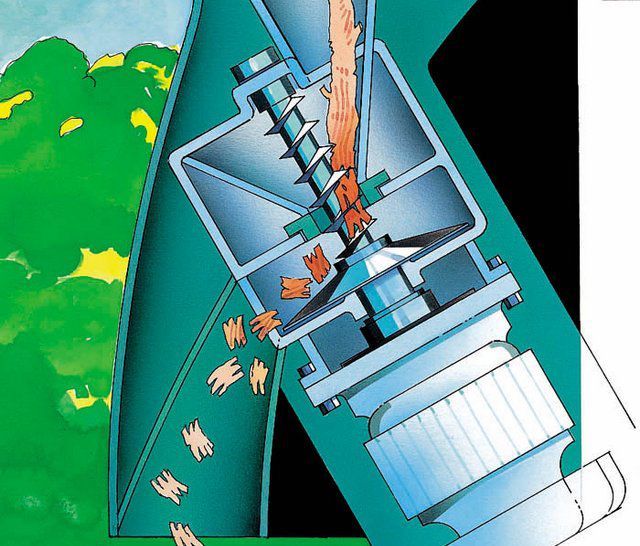

- For the processing of hard, dry branches of the trunks, it is better to use a shredder that is equipped with a milling mechanism. On the working shaft there is a cutter - a gear made of high-strength alloy, with a certain configuration of teeth and their corresponding sharpening. Large revolutions are not needed for such a cutter, which means that a gear reduction gear is provided.

The cutter gear is able to handle solid wood waste

The teeth of the rotating cutter are able to "gnaw" the sober wood of dry branches and trunks, turning them into small chips. But this mechanism does not always cope with freshly cut branches and shoots - the fibrous structure is "chewed", but may not be fully crushed.

The cutter does not have to be in the singular - there can be several of them on one shaft, with a certain angular "run-up" of the position of the teeth. And on powerful equipment of a professional class, there is often a two-rotor shredding mechanism, where two rows of cutters rotate in the opposite direction, providing crushing of even the hardest wood waste.

Twin rotor shredder grinds even the toughest waste

The convenience of the milling mechanism of grinding is also in the fact that it is enough for it to grab a long branch or trunk - in the future, the gear simply pulls it inside, while crushing it into small fragments.

- The advantages of both of the above cutting mechanisms are combined with a universal type shredder. In fact, it is also a milling cutter, but of a turbine type - instead of teeth, it is equipped with carbide knife blades located at an angle to the longitudinal axis.

Cutting device universal type

Such a structure of the cutting mechanism makes it possible to equally successfully crush both freshly cut and old, dried waste. True, garden shredders of this type are already much more expensive.

- Some models of medium and high power are equipped with a screw, screw chopping mechanism.

Scheme of work of a shredder with a screw cutting mechanism.

The rotating screw with sharply honed spiral turns perfectly copes with any type of vegetable waste - it all depends on the power of the installation itself.

Garden shredder selection criteria

Unit capacity and recycling capabilities

These two concepts, placed in the subheading, have a direct connection. The functionality of the shredder as a whole will primarily depend on the power of the power drive.

Prices for Bosch garden waste shredders

Garden waste shredders Bosch

There is no clear gradation of the entire variety of such equipment, but there is a conditional division into three groups - models of the household class, middle, semi-professional level and, finally, professional equipment.

To make it easier to perceive the criteria of such a division, it is better to present them in the form of a table:

| Shredder category | Power and type of drive | The limiting diameter of the shredded branches | "Weight category" | Applications and features |

| Household | up to 1.5 kW, electric drive | up to 25 mm | Up to 20 kg | Small summer cottage or house plots, mainly with young trees. Short cycle of continuous work. As a rule, it is a knife mechanism. |

| Middle class, semi-professional | up to 3 kW, electric drive or two-stroke internal combustion engine | up to 40 mm | up to 40-50 kg | Average households or summer cottages with an orchard, shrubs, old trees requiring regular pruning. Cope with any type of green and dry waste within the specified size range. Capable of long enough non-stop operation |

| Professional | from 5 to 9 kW, petrol or diesel drive, three-phase electric motor | 60-80 mm | up to 100 kg and more | Waste disposal in forest parks, industrial enterprises, large farms, utilities, etc. Designed for long work cycles during work shifts. |

Naturally, with an increase in the power and performance of a garden shredder, its price also increases. Therefore, before purchasing equipment, it is necessary to carefully weigh the planned volume of work to be done, the features of the recycled waste, the frequency of use of the grinder and other parameters. It will be a shame if the purchased shredder either does not cope with the load assigned to it, or if its capacity, for which a lot of money has been paid, will simply remain unclaimed.

In addition, the more powerful and productive the shredder, the larger and heavier it is. From this point of view, an adequate assessment is also needed - how much it will be possible to move it around the site, especially on the ground.

Additional criteria for choosing a shredder

There are a number of other important nuances that require attention when choosing a suitable model:

- Convenience of the receiving hopper. It can be placed vertically or at a specific angle. In some models, it is possible to change the position of the receiving funnel. For a knife grinder, a pusher must be included in the kit: pushing branches or foliage with your hands is extremely dangerous.

Chopper receiving hopper with pusher. Guiding ribs are clearly visible

On many models, the inlet can have a pronounced slit or cruciform shape, or be equipped with guiding ribs - these “tricks make it much easier to feed loose branches for processing.

Garden shredder with the possibility of differentiated feeding of different types of plant waste

Models of the middle and professional class, in addition, can have two receiving bins - each for a different type of waste. For example, the supplied soft waste goes to the knife milling, and the hard branches to the milling cutter.

It will be useful to learn how to make wood briquettes for heating from husks in our new article on our portal.

- Collecting the recycled mass can be carried out in a rigid hopper, usually included in the shredder kit.In this case, of course, it is more convenient when the hopper is made of durable translucent plastic - it is easier to control its filling level.

Shredders with regular and translucent bins for processed pulp

In other models, removable bags can be used as a receiving container, which are put on the outlet neck. By the way, on the forums you can find critical remarks of users - sometimes the bags break through sharp fragments of crushed wood flying out at high speed.

There may not be any collection at all - the outlet is located at a certain height. Allowing to substitute, for example, a basket. It is often practiced to throw crushed waste directly onto the ground of the site. In this case, models that have the ability to adjust the direction and height of the discharge will be especially convenient.

- Some models of shredders have a built-in mechanism for automatic feeding of waste to the cutting device. It is enough just to lower the branches into the receiving funnel, and then the mechanism will do everything by itself. Unconditional convenience.

- Modern garden shredders often have the ability to adjust the speed of rotation of the cutters - can be tailored to the specific type of material being processed. Moreover, the "advanced" models also have a number of pre-programmed processing programs (for example, raw wood, grass, dry branches, stone fruits, etc.).

- It's great if the reverse function is provided. This often helps to avoid chopper jamming if, for example, a too thick, strong branch has been fed. Attaching the cutter to the reverse will make it easier to get it out.

- For safe operation, electrical models must have a function of protection against accidental starting, as well as protection against self-starting after an emergency power outage. It is imperative that the power supply to the motor be blocked when the upper casing of the shredder is open.

- It is important to assess the level of noise and vibration emitted by the grinder - many modern models have special noise reduction systems. This, of course, applies more to devices with a gasoline engine.

- It is very good if the kit includes spare cutting equipment, or the store may offer to purchase it separately. This removes a number of problems with the inevitable, one way or another, dullness of the knives. By the way, you can pay attention to the fact that some manufacturers complete their products with double-sided knives. As the blades lose their sharpness, they can simply be turned upside down - the total duration of the work before going to the master sharpener or before buying a new tool is doubled.

We will not dwell on the specifics of choosing models with gasoline engines. The intricacies of choosing garden equipment with an internal combustion engine - two-stroke and four-stroke schemes, starting systems, lubrication, the procedure for preparing the fuel mixture, etc., have been given enough attention in another article on this site.

Motocos are reliable helpers in a suburban area

About how to do it right choose a petrol trimmer - brushcutter - read in a special publication of our portal.

Garden shredder models at a glance

The variety of models of garden shredders is very high, and this sometimes even makes it difficult to correctly determine the optimal model. Technique of this class cannot be called too cheap, so money should be given only for high-quality products.

The fact is that a great variety of different equipment from completely unknown manufacturers have appeared on the market, disguised as sonorous European or Russian names. The overwhelming majority of such samples are semi-clandestine Chinese manufactures in the negative sense of the word (there are a lot of really high-quality equipment from China on sale).The peculiarity of shredders is that the efficiency of their work depends not only on the drive, but also on the quality of the cutting equipment. But in this issue, the manufacturer's dishonesty is very often manifested - knives or cutters are made of outwardly beautiful and shiny steel, at first they are sharp, but literally after a few approaches they become blunt, and simply cannot be sharpened with high quality.

And if we add to this the fact that the cutting equipment is not interchangeable, then it’s not far from the situation when the recently acquired device will be idle simply because of its “professional unsuitability”.

So, if a garden shredder is purchased, then the choice of honeycombs should be made in favor of proven models of well-known companies. These include "Viking", "AL-KO", "Black & Decker", "Gardena", "Bosch". The garden equipment of Russian-Chinese production "Elitech" and "Zubr" deserved very good reviews. Traditionally, units such as Makita, MTD, Oleo-Mac are in high demand.

The table below lists several models that top the list of popular garden shredders in surveys and sales analyzes:

| Model name, illustration | Brief description of the model | Approximate price level, rubles |

| "BOSCH AXT 25 TC"

| One of the most popular models among all garden shredders in general. 2.5 kW electric motor. The versatile "Turbine-Cut" cutting mechanism allows you to process any plant material. Productivity - up to 230 kg / h. Barrel thickness - up to 45 mm. Equipped with a collection of recycled waste, with a capacity of 53 liters. Convenient wheel travel and handle for field transportation. Chopper weight - 30.5 kg. | 32900 |

| "VIKING GE 250 S"

| One of the main authorities in the field of gardening equipment is VIKING. The presented model is characterized by a powerful electric motor - 2.5 kW. The thickness of the processed branches is up to 35 mm. Knife system "Multi-Cut 150" with a two-level Z-shaped arrangement of blades. Reliable emergency interlocking system. Convenient wheel travel, stable working position. Assembled height - 1440 mm. Weight - 25 kg | 18000 |

| "OLEO-MAC SH210E"

| Garden shredder with powerful electric motor - 2.1 kW. Low noise level during operation. The frame and body are made of metal, ensuring high strength. Convenient wide wheels for moving around the site. Wide loading hopper of the receiving hopper. Two pairs of knives - straight and side knives. The thickness of the processed branches is up to 40 mm. The collecting hopper is not provided. Weight - 35 kg. | 37000 |

| "AL-KO EASY CRUSH МH 2800"

| Affordable price and excellent performance are the reasons why this shredder is at the top of the rankings. Electric drive with a power of 2.8 kW. Integrated bin for collecting recycled waste with a capacity of 50 liters. The maximum diameter of the branches is 42 mm. Cutting unit - knife, additionally equipped with a roller mechanism for material retraction. Chopper weight - 25 kg. | 15600 |

| "WOLF-GARTEN SDL 2500" | A reliable, compact and inexpensive unit that can handle large volumes of waste recycling. Electric drive - 2.5 kW. Cutting system - several knives combined into rollers (milling cutter) for high-quality wood crushing. The work does not require high revolutions of the cutting mechanism, therefore the shredder has a low noise level. The maximum diameter of the branches is 40 mm. The mass of the device is 24.5 kg. | 13000 ÷ 14000 |

| "VIKING GB 370"

| Petrol garden shredder equipped with 3.3 kW four-stroke engine. Able to process branches up to 45 mm thick. Cutting system - "Multi-Cut 370", with straight and reversible knives and turbo cutting disc. Convenient mouth for material feeding (it can be in two versions - vertical and inclined). Mechanism for automatic feeding of material for cutting. Height - 1400 mm. Weight - 43 kg. | 72000 |

| "MTD ROVER 464 Q"

| High functionality petrol garden shredder. Powerful motor - 5.5 kW. Combined chopping system - rotating cutting knives plus 12 threshing cutters. Processing of barrels up to 75 mm in diameter is provided. Material auto-pulling system.Two feed openings - for thick branches and for thin and small plant debris. Possibility of lowering the loading chute to ground level for direct raking of debris. Robust frame with comfortable wheel travel. Weight - 75 kg. | from 70,000 |

Prices for popular garden waste shredders

The author of the publication expresses the hope that the information provided will help the interested reader make a really correct choice of the optimal model of a garden shredder.

Video: a few tips for choosing a garden shredder

Design features

A grass chopper is a special device for chopping grass, which is indispensable in a subsidiary farm.

After processing the cut grass, it can be used as soil fertilizer, insulation material in winter, or pet food.

Such a tool is able to finely chop a large volume of weeds or cut grass in just a few seconds. This is a significant saving of time and effort for the owner of the personal plot.

A standard manual grass cutter includes the following parts:

- steel frame;

- electric motor;

- cutting knives;

- working shaft;

- pulley;

- belt;

- container for receiving herbs;

- protective cover;

- cable.

Homemade garden grass cutters are compact in size and light in weight, which greatly facilitates their operation.

However, they have good performance. The unit can be fitted with both a gasoline and an electric motor:

- Gas engine - a more powerful device that allows you to chop the branches of shrubs. Its main advantage is the ability to operate even in those areas where there is no electricity. Disadvantages - heavy weight, noisy work.

- Electric motor - not as powerful as gasoline, but lighter and more convenient to operate. Such a device is started by one turn of the toggle switch. Its main disadvantages are dependence on the power grid and limitation on the thickness of the stems of the processed vegetation.

Grass cutter with electric motor

A DIY electric grass cutter is a useful tool for your own backyard.

With its help, it is convenient to prepare food for animals from grass and small twigs, especially from nettle, which is considered very useful for livestock.

Household cultivator apparatus

The device, made on the basis of a drive from a cultivator, is similar in design to a crusher from a drill. The device has increased performance, allows you to simultaneously process a significant amount of grass... In the process of assembling the grass cutter, the following is used:

- Cultivator drive;

- Hacksaw blade;

- Sleeve for fastening a knife;

- Self-tapping screws;

- Capacity;

- Table top;

- The frame for the table top.

Homemade greenhouse from old window frames with your own hands

After fixing the drive on the tabletop with a hole for the motor, using self-tapping screws and brackets, it is necessary to fix the mechanism casing to the bar. A funnel from the drain can be used as a bell, the entire assembled structure is installed and fixed on the table. To prevent the table top with the device from slipping due to vibration, it is recommended to install limiters.

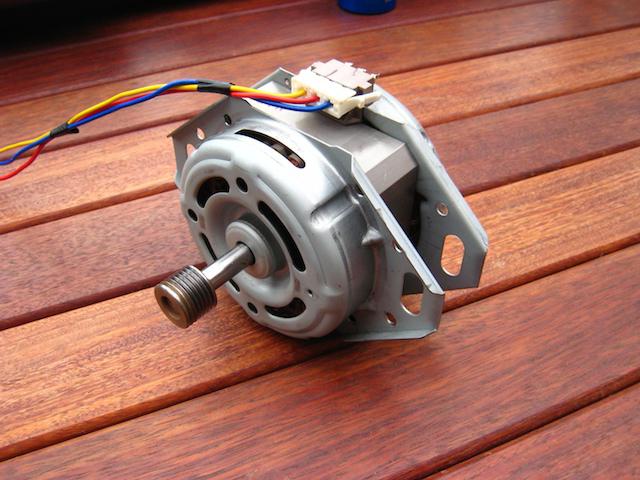

Varieties of engines for assembling homemade products

Electric and gasoline engines removed from unused equipment are used as a drive for homemade products. Each of these two options has its own advantages and disadvantages. Models with an internal combustion engine are more convenient in that their operation does not require a nearby power supply. But in general, they are more expensive and have a more complex structure than their counterparts equipped with an electric motor. Therefore, it is easier to make electrical equipment, moreover, more compact.

The maximum thickness of the cut branches that the chipper can grind depends on the power of the electric motor installed on it and the characteristics of the blades.

What is silage used for

Many summer residents-gardeners, living outside the city, grow in the country not only vegetables and fruits, but also keep chickens, pheasants, quails, rabbits and various domestic animals. Chopped silage grass can be an excellent food for pets, you just need to take care of the availability of a suitable chopper in the subsidiary farm, which can easily grind grass and hay.

Experienced gardeners use this milled grass as mulch and premium organic fertilizer. It will only be necessary to provide the finest possible grinding of the grass, as a result of which the mulch layer will turn out to be dense, which is necessary to retain moisture and heat in the ground.

With this versatile equipment, you can easily grind cereals, vegetables and fruits, which allows you to make high-quality feed for livestock, eliminating the need to purchase expensive compound feed.

Engine power classification

Amateur class. It features a disc cutter system driven by a 1.6 kilowatt electric motor. The unit of this class is designed for crushing plant debris and branches with a diameter of 30 millimeters.

Medium power class. The engine power of the installation can reach 2.5 kilowatts. The system of knives of such units is milling, therefore they are used for crushing large plant debris and branches with a thickness of 40 mm.

Professional class. The engine power of this class unit reaches 4 kilowatts. The knife system is milling. With its help, large branches with a diameter of 80 mm are processed and compressed. If you use such a grass shredder, then labor productivity will increase and it will be possible to save space on the site.

Types of cutting attachments used

Homemade products, like factory units, are equipped with cutting attachments of various types:

- disc (with three blades);

- milling;

- milling and turbine (universal).

The first variety is flat blades. When rotating, they grind plant debris. If you have to recycle branches, then these blades quickly become dull. Milling knives are a cutting shaft in the form of gears from circular saws. They finely grind dry waste from branches and grass, and wet ones clog cutters. Turbine milling cutters are able to cope with thick and not dried branches, but making them yourself is difficult.

At home, knives from lawn mowers or made from wood saws are often used.

It should be borne in mind that the degree of processing of plant waste directly depends on the installed cutting attachments. At the exit, they receive pieces of branches from 10 cm in length or shavings, dust.

Types of cutting parts

A grass thresher should be designed with sharp and strong blades in order to grind not only the grass, but also the branches. Depending on agricultural needs, they can be of several types:

- circular knife, consisting of three blades (for grass and thin branches);

- milling knife (for larger branches);

- milling-turbine knife (copes with large and small branches at the same time).

The first type of knives is well suited for processing small plant debris. If you grind a large one with them, then the blades will deteriorate quickly enough... A unit with such a knife will be useful for a gardener who does not need to process large volumes. The other two are suitable for working with large elements (good solution for medium to large farmland).

Recommended: How to create a shredder for heating with your own hands

Types of devices

Grass grinders differ not only in the way they are made, but also in the type of engines.It was mentioned earlier that the motor can be electric. A gasoline engine can also be attached to the hand crusher.

Electric units are always inferior in power to gasoline, and they need a power supply to operate. Such equipment can be an excellent solution for those who do not keep livestock or poultry, but at the same time have a small garden. It will not be able to handle large volumes and handle large amounts of grass.

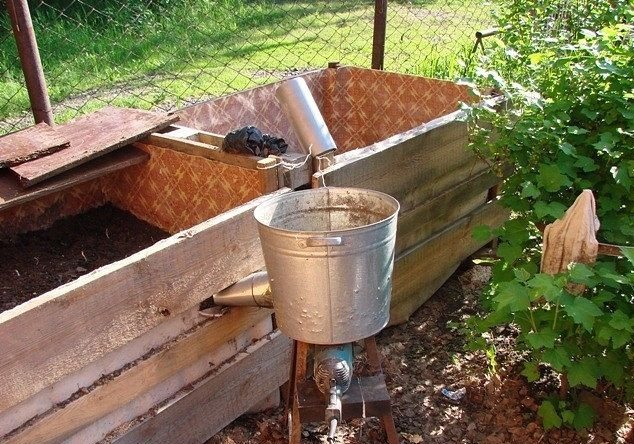

Garden Shredder From Washing Machine

An old Soviet-made washing machine with a metal body is a technique that contains almost all the necessary parts for assembling a garden shredder. You only need knives with fasteners, as well as a wire for an extension cord.

You can use an old wood saw to make a cutting attachment.

Of the tools you will need:

- angle grinder;

- pliers;

- spanners;

- screwdriver;

- electric drill;

- a hammer;

- tape measure with a marker.

The washing machine motor has a low power (different for different models), indicated in the instructions for household appliances or on the nameplate of the electric motor. Due to the fact that usually its value does not exceed 500 watts, with the help of the created unit it will be possible to grind only straw or grass.

A washing machine shredder is made as follows.

- The body of the machine is cut in height so that it is convenient to work with the unit.

- On the side at the bottom, a rectangular hole is cut in it with a grinder 20 cm wide and 7 cm high, intended for ejection of ground plants.

- Around the slot, a kind of casing is made of tin, which will direct the grass mass into the collection container, while preventing it from flying around the sides.

- Make legs.

- Attach the body to the stand.

- 2 holes with a diameter of 7 mm are drilled on the shaft of the electric motor. Then a threaded sleeve is pushed onto it, as well as holes at the end longer than 5 cm, fixing it with bolts.

- An electric motor is attached under the bottom of the box using studs and nuts.

- Inside the casing, the knives are fixed on the sleeve, placing them above the hole for ejecting grass or at the same level with it.

- The box is attached by welding or bolts to the stand.

The result is a technique similar to the one shown in the photo below.

The start button will fit from a converted washing machine. You just need to take care to connect an extension cord of sufficient length.

The device and operation of a grass cutter from a modern washing machine are shown in the video

Making the simplest shredders

There are many drawings for the manufacture of such equipment using improvised units. You can find an original do-it-yourself grass cutter in the Modelist-Constructor magazine, made from a drill or an old washing machine. Such work is not particularly difficult, therefore, even if you do not have the relevant experience, it will not be difficult to make a feed chopper yourself with your own hands.

Using an old drill

A simple hay cutter can be made from an old waste drill. Despite its simplicity, this technique will be versatile and reliable, making it easy to process even large volumes of grass and straw.

For the manufacture of hay and straw chopper with your own hands you will need:

- Working drill.

- Empty metal bucket.

- A set of knives or a cutter attachment.

It will be enough to use a drill with two modes of operation, which develop a power of about 850 watts. It is only necessary to sharpen the knife correctly, which should be as sharp as possible, which will allow the cutting tool, even at a low speed of rotation, to quickly dissect the grass, crushing it into a fine porridge. The body of the device is made of a metal bucket, in the bottom of which a hole should be made and a drill with a sharp knife inserted into it.

A feature of grass shredders is the one-sided sharpening of the knife, which is oriented downward with its sharp sharpened plane. Only such a cutting tool will chop up the grass, which can then be used for livestock feed or as an excellent fertilizer. Making a homemade unit does not present any difficulty, your costs will be minimal, and you can cope with such work in literally 15-20 minutes.

Vacuum cleaner shredder

The principle of operation of such a sechkarni is similar to the previous device. Here, an appropriate metal or plastic container is used, inside which a sharp knife is located. It is powered by an electric motor and quickly crushes the grass that collects in the lower compartment, making it easy to unload finished silo, simplifying the processing of raw materials.

If in our previous version of the grass cutter from the drill the grass was already in the container in which the cutting tool was placed, then in this case the raw material is fed through the top, and the finished chopped grass comes out through the lower holes. The presence of a protective cover allows to protect the crushed silage from scattering during the operation of the unit.

Such a feed chopper is made on the basis of an old Typhoon vacuum cleaner. However, you can use housings from old Soviet vacuum cleaners, which will have upper holes of suitable size. Any cylindrical container, pipe section, bucket, saucepan, etc. will work perfectly. The delimber drive can be made from a motor from an old washing machine with a power of about 180 watts.

The knives are made from old steel blades. The racks are made of a metal profile measuring 15 by 15 millimeters. The vegetable grinder knives are mounted on a 40 mm high bushing. The bushing will have to be turned on a lathe or selected to fit the size.

The motor with the removed pulley must be fixed on the studs at the bottom of the container. 32mm plumbing nuts can be used to secure the cutting tool. On the motor shaft with its back side it is necessary to carve out the platform, which will allow the bushing to be securely fixed with the locking bolts.

The knives themselves can be made from a hacksaw blade, from which four blanks are cut with a grinder. A square hole with a diameter of about 26 millimeters should be drilled in the center of each workpiece. The cutting edges of the workpieces must be sharpened, for which you can use a sharpener. After that, it remains only to fix the bushing, on which the knives are attached with the help of bolts.

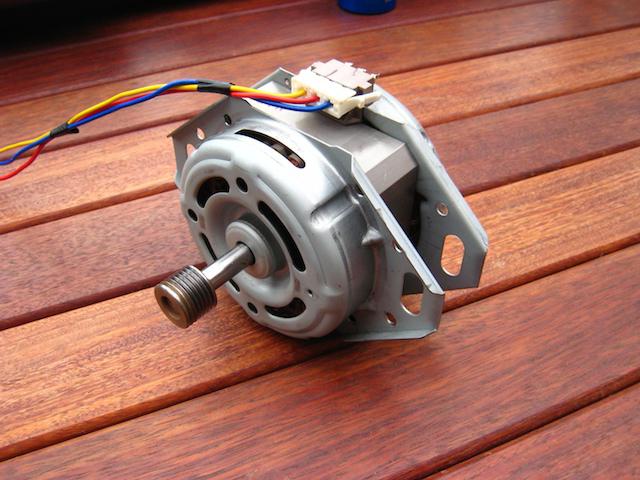

Shredder from an unnecessary electric motor

This grass shredder can be made from scrap parts using any working electric motor. To make such an elementary grass cutter, you will need:

- Electric motor producing 3000 rpm.

- An old aluminum pan.

- Plug and cord.

- Power control button.

- Hacksaw for wood.

The container is made of an aluminum pan, at the bottom of which a small hole should be made for attaching the sleeve. Knives are made from three to four blanks from hacksaws for wood. Do not forget to pre-sharpen their cutting edges, which will ensure high-quality chopping of grass and hay. An electric motor powered by a household electrical outlet is installed under the pan... Start button located at the rear of the platform. The completed sleeve is pushed at one end to the drive of the electric motor, then it is threaded into the hole in the pan, after which the knives are pushed onto the axle and fixed with locking bolts.

Chopped silage, made on a homemade device, will go to feed poultry and livestock or can be used for mulching plantings.

Methods for making a thresher

A homemade herb chopper has many benefits.This is not only beneficial, but also very convenient, since all the details are at hand. There are several ways to make your own grass chopper:

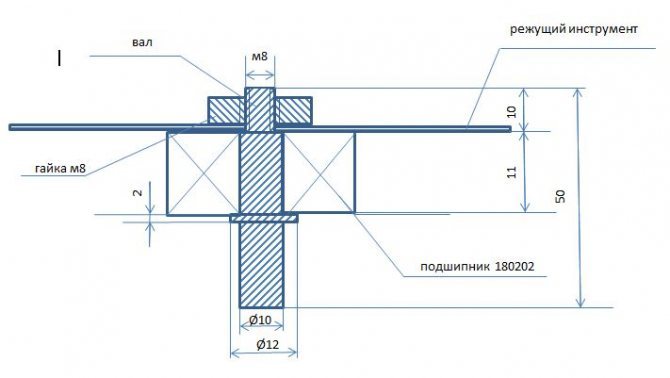

- The first way is to use a conventional drill, and the thresher itself will work like a blender. You will need a drill itself (with a power of 620 W), an iron bucket (medium size), a shaft with a knife, as well as a rod 30 cm long - 40 cm and a diameter of 10 mm - 12 mm. The rod will act as the basis of the structure; it must necessarily have a thread of 40 mm, on which the blade will "sit", fixed with two nuts. The knife itself can be part of a scythe or any other suitable blade.

- The second method is a do-it-yourself grass grinder, which can be made using an old Typhoon vacuum cleaner. Such a unit will prove to be very practical, since it is very productive. It will be provided in advance for the supply of the received raw material through a special hole. From the vacuum cleaner itself, you only need its body and any 180 W electric motor. The rest of the details are the same as in the first method: a knife and a 40 mm rod as an attachment. Next, cut a hole for the platform at the bottom of the body from the vacuum cleaner, and attach the motor from below. The knives are fastened with nuts.

- The third way is to use an old washing machine. The principle of operation of such a grinder will be identical to that constructed from an old vacuum cleaner. In this case, the main advantage will be a larger volume. You will need a sleeve of at least 50 mm, and the body of the washing machine itself can be cut at your discretion.

Recommended: Where to start with separate garbage collection

How to make a grass chopper for poultry or livestock - you need to pick up any container, which can be not only a washing machine or vacuum cleaner, but even an ordinary large saucepan, and attach the blades to its bottom on the sleeve.

DIY grass cutter

From a gas cylinder

Instructions:

- Cut out a ring 1 of the required size from a gas cylinder, and a cover 2 of a slightly larger diameter from a steel sheet 3 mm thick (fig. 1)

... We press them together with clamps and weld from the inside. We clean the outer protrusions of the resulting casing with emery. - On a lathe, we grind a hole 4 in the lid for the knife shaft 6 and make markings for the clamp 3.

- We cut out the ring for the clamp from the pipe, weld the jaws to it, drill a 7 mm through hole in them for the bolt 7. Then we cut the ring between the jaws and, placing the clamp on the grinder, insert a metal spacer between them. We tighten the bolt, allowing the clamp to move freely over the grinder. Then we weld the clamp to the circle (according to the markings), leaving 1/3 of the circle free near the jaws.

- We weld a piece to the cover of the grass cutter pipes 5

, cut a hole inside with electric welding, clean the edges with a grinder. - We make a knife from a saw blade, sharpen it, burn a hole by welding (we do not recommend drilling, spoil a lot of drills) and expand it with emery nozzles (fig. 2)

... We install it with the cutting edges up. - We put the finished casing with a knife on the motor shaft.

Blueprints:

From the grinder

Today, almost everyone on the farm has such a power tool as a grinder. It is ideal for making a manual grass chopper.

In addition to the grinder, you will need the following tools and parts:

- a hammer;

- screwdriver;

- engine;

- steel brackets, bolts with nuts;

- shaft;

- frame;

- cutting discs or blades;

- pulleys;

- grid;

- container for chopped grass.

First of all, you need to securely fix the engine, for this we take metal corners and cook a frame from them. Next, the grinder should be attached as firmly as possible to this frame, since it works at very high speeds and if it comes off, it can cause trouble.

Then, on top of the grinder's shaft (it is located upward), a metal container is installed, grass will be loaded into it and, in fact, the cutting process will take place in it.

It is best to keep the steel of the container as thick as possible, otherwise, if the knife suddenly unscrews while the grass cutter is working, it can pierce the steel and fly out.

A steel corner is attached to the bottom of the container; it is needed in order to keep all the grass mass from scrolling inside the container. The corner is fastened with bolts and nuts.

Now you just need to install a lawn mower knife on the grinder shaft.

For convenient collection of chopped grass, a special sleeve was made from thin metal; it can be directed into a special box for collecting flour from grass, or simply substitute a bucket. This completes the assembly of the grass cutter.

From the washing machine

Consider another way to create a grass cutter from scrap materials.

From the materials we need:

- electric motor from a washing machine;

- the body from the Uralets vacuum cleaner;

- durable sheet metal to create a knife;

- a plastic bucket or other container to create a bunker;

- a plastic bucket to create a grass catcher;

- steel corners;

- electric welding;

- Bulgarian;

- drill;

- screws with nuts and more.

Step-by-step instructions for making a tool:

- Preparing the body. According to the diagram, the body is taken from a vacuum cleaner, at the bottom of which a hole of 70x70 cm is made to dump the crushed raw materials.

- Installation of the electric motor. The unit is installed on the bottom of the product body with the shaft up. The motor itself is taken from the washing machine. The knife is cut from sheet iron with a grinder. Its edges are raised slightly upward.

- Hopper and grass catcher. These two containers are made from plastic buckets. They are lightweight and the material does not rust, which is very important in this case. A bag is put on top of the catcher of the finished cut of greens so that it does not scatter in different directions during the cutting process.

- Tool frame. This is an important structural element on which all other parts are fixed. For its manufacture, strong metal corners are used, which are connected to each other using a welding machine.

This completes the assembly of the tool. With its help, the cutting of feed from weeds, grass and small branches for animals will be carried out quickly enough.

From a drill

An excellent grass cutter can be easily built from a conventional drill. How exactly this simple device works can be seen in the video below:

So, the grinding process resembles the work of a food processor: in a cylindrical body, the role of which is played by a simple bucket, there is a sharpened knife.

When rotating it in a circle at high speed, the grass is dissected. To make this grass cutter, a two-mode drill "Temp" with a capacity of 850 watts is used. The knife is made of a hacksaw blade. The whole secret is hidden in the sharpening of the knife.

If done correctly, the grass will not wrap around the blade. Keep the knife clean and free of greenery. The knife is sharpened with one-sided sharpening.

It should be oriented with the sharpened plane down. If you have to chop fresh grass, the best shape of the knife will be a narrow diamond, so that the cutting edge comes to naught at an angle to the edges.

As a last resort, you can round the blade to a point.

Then the grass, which is subjected to centrifugal force, slides along the cutting edge of the knife straight to the edges. It is easily cut and never wrapped around the knife.

Homemade straw chopper

The three previous units have successfully turned grass into silage. But if we need a chopper not only for grass, but also for hay, it is worth taking a closer look at one more invention, which is presented in great detail in the video below.

Manual chopping

A small amount of raw material can be crushed using a hand-held metal cutter put on a long handle.

The chisel is a sharply sharpened triangular plate, the longest side of which is directed downward.

Freshly cut grass, weeds, leaves, tops are laid out on the ground with a layer of 10-15 cm and cut into pieces. The tool must be lowered sharply. After each impact, the plant mass is divided into smaller and smaller pieces.

Homemade grass grinder from a grinder

A grinder grass chopper is a fairly simple and quickly implemented option. To implement the project, you will need to stock up on the following details and materials:

- steel corners;

- metal container (conventional boiling);

- homemade or ready-made knives (for example, from a lawn mower);

- fasteners;

- sheet tin.

Of the tools you will need:

- electric drill;

- welding machine and electrodes to it;

- angle grinder to cut corners;

- spanners.

To assemble a shredder with your own hands on the basis of an angle grinder, capable of grinding not only grass, but also branches up to 4 cm thick, it is recommended to use an electric tool with a power of over 3 kW.

The creation of a grinding unit is carried out in the following sequence:

- the corners are cut into pieces with a grinder;

- a frame resembling a chair is welded from them;

- weld on a shelf from a piece of sheet metal;

- to the frame made (on the stand), attach the grinder with clamps, placing it with the shaft to the top;

- cut a hole about 10 by 10 cm on the side of the boil;

- a sleeve, for example, made of tin, is attached to the slot, through which the ground plant mass will be dispensed from the container;

- make a hole in the center at the bottom of the boil;

- install the container on the grinder shaft and attach it with bolts or self-tapping screws to the metal frame;

- place a knife or disc on an angle grinder.

As a result, you get the design shown in the photo below.

The dimensions of the corners are selected individually so that it is convenient to handle the mechanism.

It should be remembered that the frame must be stable. The safety of working with the device will depend on this.

A bucket or other container is placed under the pipe for dispensing chopped grass with branches while working with the unit so that the processed plants do not scatter.

The created device can be improved. To do this, you need a nozzle on the grinder shaft about 15 cm long with two knives: at the upper end and in the middle. The blades are separated by a mesh fixed to the wall of the casing.

Making knives and chopper rack

Making a garden electric grass chopper with your own hands, at the next stage you need to tackle chopping knives, which, as a rule, are made from pieces of an old saw. The racks that will hold the structure must be made of durable material, its width must be set by the master himself. The legs of an old stool are perfect for this.

The chopping knives must be fixed on a special sleeve. You can do it yourself or order a turner who will use special equipment. When making a do-it-yourself garden electric grass chopper, the sleeve must be made in such a way that its height is 50 centimeters. To determine the appropriate diameter, you must be guided by the dimensions of the nuts that are used to clamp the blades. The most suitable type of nut is plumbing.

Tips for making a grass cutter

The magazine "Konstruktor" very often publishes advice on the manufacture of various types of grass cutters, feed cutters and straw cutters. Together with the tips, drawings are also published, as well as assembly diagrams of various parts and components.

Most grass cutters work like a food processor: the grass is chopped in a container with cutting knives. This explains the simplicity and lightness of the device.

But in order for a do-it-yourself grass cutter made of any materials to be more functional, you can do the following:

- Sharpen only one side of the knives if you plan to chop up plant branches,

- If you plan to use the grass cutter as a forage crusher, the knives need to be sharpened on both sides,

- For chopping only grass, use only diamond knives,

- Replace conventional mounts with metal frames - this will increase the strength of the device,

- Sheathe the cutter with a sheet of metal from the outside. This not only reduces the risk of injury, but also prevents dust from entering the machine.

Grass cutter from trimmer

A garden shredder can be made using a gasoline or electric trimmer. This will cause the tool to work upside down. To create equipment designed to chop grass and thin twigs, you will need, in addition to brushcutters with cutting attachments, the following materials:

- a plastic or metal container with a volume of at least 50 liters;

- about 1 sq. small mesh steel mesh;

- about 3 meters of metal tube (aluminum or steel), half an inch in diameter;

- a piece of board or moisture-resistant chipboard, plywood of such a width that a trimmer fits on it;

- clamps that will attach the brushcutter to a wooden base;

- self-tapping screws, bolts, nuts, washers;

- wooden blocks (5 by 5 cm is enough).

To assemble the chopping mechanism from the trimmer, you will need to use the following tools and devices:

- a screwdriver or a screwdriver with bits;

- electric drill with a set of drills for wood and metal;

- an electric jigsaw with files for cutting metal or its manual analog;

- hammer;

- open-end or socket wrenches;

- punch;

- an anvil or a flat iron plate.

A punch is needed so that it is convenient to drill holes with an electric drill. This tool is pointed at the point where you want to drill through the metal. Then they hit him with a hammer. The drill does not slip out of the recess obtained while drilling a metal part.

Hole punch set

Preparatory activities

A grass cutter from a brushcutter is made in a number of stages. Initially, they are prepared in a container where the grass and branches will be ground:

- markings are made at the bottom (along the perimeter) for four trapezoidal holes with rounded corners;

- drilled in each drawn segment of the hole with a cross section of 1 cm;

- a jigsaw file is inserted into them and trapeziums are cut;

- process the sections with a file or sandpaper;

- a hole is drilled in the center of the bottom for the chopper shaft;

- a circle is cut out of a steel mesh with dimensions along the diameter of the bottom;

- with the help of small scraps of boards or blocks, the prepared mesh fragment is fixed to the bottom of the container;

- legs are made of metal tubes for a container, attaching them to the tank with bolts.

Wooden pieces are fixed with self-tapping screws, twisting them from the inside of the tank into metal jumpers between the cut trapezoids. In this way, the net is securely attached to the bottom of the container.

Legs are made in the following way:

- bend the tubes in a vice or with a pipe bender in the form of the letter "P";

- the ends of future supports are flattened with a hammer;

- 2 holes are drilled in them on each side (6.5 or 8.5 mm in cross section);

- fit the workpieces to the bottom of the container and mark the points of the bolted joints;

- drilled at the hole mark;

- using bolts with washers and nuts, attach the footrest to the casing.

After preparing the casing, in order to reduce the dimensions of the created mechanism, perform the following operations:

- disassemble the trimmer by disconnecting the motor, bar and cutting attachment from each other;

- a fragment of about 20-40 centimeters in length is cut off from the bar with a cable;

- collect a brushcutter;

- check the performance of the equipment.

Chopper assembly

If the trimmer works well after assembly, then a grass trimmer is created from it.

- The brushcutter engine is attached to the board with clamps.

- The bar is fixed on a wooden base using clamps and a brushcutter handle.

- Connect the cutting attachment to the end of the bar, previously inserted into the hole in the bottom of the casing.

- The mechanism is started and tested in operation.

After the actions taken, you will get an assembly, a photo of which is presented below.

If the trimmer used to assemble the shredder is equipped with a gasoline engine, then the motor is positioned on the base so that it is convenient to fill in fuel, start the device and adjust its operation (speed).

Cutting attachments are equipped with knives or fishing line - it depends on the thickness of the plant stems to be chopped.

Top 5 gasoline grinders

MTD 465 (MTD ROVER 464 Q)

The device is equipped with a powerful gasoline engine, which makes it completely independent from the power supply. The loading hopper is large, due to which large diameter branches can be loaded there, in addition, there is another receiver that is placed on the ground. It is convenient to rake the garbage there directly with a rake, it will be pulled there like a vacuum cleaner, after which the waste is ground practically into dust.

The engine is compact, equipped with a system of valves closely spaced to each other, which increases the number of revolutions, reduces fuel consumption. The motor has a muffler that makes the operation as quiet as possible, saves oil.

Benefits:

- Autonomous work;

- Low fuel consumption;

- Ergonomic handle, height adjustable;

- The volume of the waste container is 50 liters.

Disadvantages:

- Significant weight - about 29 kg, which makes it difficult to transport around the site.

4. Patriot Garden PT SB76

This unit is a multifunctional design with a Briggs & Stratton motor and is used for thoroughly chopping dry and semi-dry branches, twigs, and various plant waste. The upper hopper is designed to load fresh, moist or soft material, as well as branches with a diameter of up to 1 cm. Grind branches, whose circumference is not more than 76 mm, and turn them into chips with a separate receiver.

The device is equipped with a reliable stainless steel case, which is characterized by high build quality, due to which these products are absolutely safe during operation. The motor power is 6.5 horsepower, the highest speed of rotation of the knives is 3600 per minute. The product is quite heavy - it weighs about 70 kg, so a special mount is provided for transportation, which allows it to be transported as a trailer to a car.

Benefits:

- Good build quality

- High power;

- Performance;

- Long service life.

Disadvantages:

- Large mass;

- It makes a lot of noise during operation.

Champion SC2818

This design is specially designed for only cut grass, fresh branches and leaves in summer cottages. The main working element of the device is a four-stroke engine with a power rating of 2.5 horsepower. It is started by a manual starter and has a long service life and excellent reliability. The fuel tank holds almost one and a half liters of gasoline - the manufacturer recommends filling at least AI-92. The cutting discs are located on the crankshaft.

More: TOP 10 best hot and cold smoked smokers

Branches are chopped with flat knives, and smaller waste is passed through a V-shaped knife. The crushed waste goes out through a special pipe and falls into a 10 liter bag. The maximum diameter of loaded fresh branches is 28 mm, it is strictly forbidden to lay waste of a larger diameter or dry garbage, since they will quickly deteriorate the knives.

The set includes an ergonomic pusher that fits comfortably in the hand.You don't even have to press hard on it. The entire structure is located on a metal base, which makes it stable even on uneven surfaces. The equipment weighs only 16 kg, it is convenient to carry it from one place to another.

Benefits:

- Acceptable cost;

- Reliable work;

- Very sharp knives;

- Easy to maintain.

Disadvantages:

- It is possible to work only with fresh material;

- In some models, the knives are at a slight angle to each other, which can cause them to jam.

VIKING GB 370

One of the best gasoline-powered wood chippers. It moves around the summer cottage due to the presence of two metal wheels in the structure. The device has a low weight, which makes it the most mobile among all gasoline grinders.

The design has good build quality, the knives are sharp, parallel to each other, moving at a speed of about 4000 rpm. This allows you to recycle not only vegetable waste, but also all sorts of household waste - polyethylene, plastic and other unnecessary trash. The maximum diameter of branches that can be placed in the receiver is 45 mm, the weight of the device is 44 kg. Runs on gasoline of the grade not lower than AI-92.

Benefits:

- Modest overall dimensions;

- High power - 3.2 horsepower;

- Reliable system of protection against injuries;

- Does not make too much noise during operation.

Disadvantages:

- High price;

- Knives periodically jam.

1. Caiman DEVOR X50S

Can be used for various vegetable and household waste. The design is based on a high-power, four-stroke engine - 5 horsepower, which can withstand even severe shock loads. The device operates on the basis of the latest technology of double shredding - it implies the presence of a whole system of knives: two sharp self-sharpening discs and one breaking knife.

This unit will easily cope with branches up to 45 mm in diameter. The body is made in such a way that it can easily find a fulcrum even on a not too flat surface. Maintenance is very simple, the equipment emits a minimum level of noise, which allows it to be used even in the vicinity of residential buildings.

The shredder has a reliable safety system that blocks the operation of the knives at the moment the hatch is opened to clear the system from stuck branches. The loading hopper also meets all safety requirements - under no circumstances will a person working with it be able to reach the knives.

Benefits:

- Reliability;

- Ease of use;

- Slight amount of noise;

- Powerful engine.

Disadvantages:

- Except for a large weight, it was not found.

The easiest way to get a beautiful front lawn

You, of course, have seen the perfect lawn in the movies, in the alley, and possibly on the neighbor's lawn. Those who have at least once tried to grow a green area on their site will no doubt say that this is a huge work. The lawn requires careful planting, care, fertilization, watering. However, only inexperienced gardeners think so, professionals have long known about an innovative tool - liquid lawn AquaGrazz.

Required parts for its manufacture:

- motor;

- knives or discs;

- shaft;

- bolts, nuts;

- container;

- protective frame;

- auxiliary materials: screwdriver, grinder, hammer.

Such an apparatus works close to the action of a food processor. The voltage from the motor goes to the shaft with knives, which grind the incoming branches or grass, and then the processed material comes out through a special hole in the box and goes to compost, feed for animals and birds.

This unit can be easily made using improvised materials that each owner has in his house, and the missing parts can be purchased on the market. On the net you can find a video with a step-by-step assembly of shredders.The main thing is to decide on the type of device, draw drawings and prepare the necessary parts for assembly.

What else can you make a shredder

There are many different options for creating garden shredders with your own hands: from the simplest ones, which only allow you to grind the grass, to more structurally complex, powerful units designed for wood up to 10 cm thick. Accordingly, for the practical implementation of the conceived, different details, different costs of time and money will be required.

To collect equipment for processing plant waste, in addition to the considered options for old or unnecessary tools or equipment, you can use the following devices:

- drill or perforator;

- an old working vacuum cleaner;

- unnecessary power saw;

- motor from the pump;

- gasoline or electric walk-behind tractor;

- any electric motor of suitable power.

A drill with a perforator, if you use them to grind the grass, does not need to be altered at all. It is enough to make only the attachment with the blades. The created device will work like a blender, crushing soft plant stems in a container in small portions.

What is a branch and grass shredder for?

Owners of their own land plots have to spend a lot of time and effort to tidy up their garden or vegetable garden. To facilitate heavy manual work, people have come up with electric grass shredders that can quickly and effortlessly get rid of twigs, grass and dry leaves.

The device from the pump "Agidel"

To make a productive crusher, you need to have a drawing of the device and an Agidel pump with a 3000 rpm motor, operating from a 220 V mains voltage. A bucket, a tank or a saucepan is suitable as a grass cutter capacity; knives can be made from a broken hacksaw blade.

You will also need an engine from a washing machine, a cable and a button to start the device into operation.

Poultry will be grateful to the owner for fresh grass silage mixed with mixed feed or bran. Low-power small-sized grass grinders can work anywhere: indoors, outdoors, under a canopy.

The main requirement for the operation of a device equipped with cutting tools and powered by electricity is the operator's own safety precautions.

A gasoline manual shredder is often used directly at the point of collection of raw materials, equipment with power supply can only be stationary. To reduce vibration in the crushing plant, it is recommended to install two knives crosswise. The forage cutter will cope with plants of leguminous crops and meadow grasses.

Electric Snow Blower Choice: Electric Snow Blowers

The nuances of operating homemade equipment

A self-made shredder is essentially three in one: a chopper for branches, a straw chopper, a mechanism for cutting grass. It helps to significantly facilitate domestic work associated with the disposal of plant waste, as well as feeding poultry and livestock.

If you have to process grass in small quantities, for example, for chickens, geese, ducks, then quite simple devices that work from human muscle power are enough, for example, a hand pruner.

For homemade electrical engineering, it is recommended to install a separate differential circuit breaker to provide reliable protection against electric shock in case of unforeseen circumstances. In any case, making a garden shredder yourself, you must follow the safety rules. It is also worth adhering to them during the operation of the mechanism. It is recommended to wear goggles, suitable protective clothing and check the reliability of fastening of structural elements before working with equipment.When creating a homemade unit, it should be taken into account the forthcoming amount of work, as well as the nature of the vegetation being processed, in order to select the engine of the required power and the desired design of the knives. This will allow the made device to cope with the assigned tasks without any problems.

Precautions

A grass chopper is the simplest means of small-scale mechanization. But if used improperly, there may be a risk to human life. To prevent this from happening, you should adhere to some rules for safe work with the unit.

- Wear protective goggles or a mask while working in order not to be injured by flying chips.

- Gloves should not fall off your hands.

- In the absence of a self-tightening device on the unit, work with a special pusher.

- Shred branches of the thickness allowed for this type of unit.

- The funnel should not get stones, glass, clothes, plastic objects.

- If the plant is processed with roots, the earth is shaken off from them.

- The branches should not dry out. When they are wet, they crumble more easily.

- In the absence of a curtain preventing access to the blades, it is forbidden to work on the machine.

Safety precautions when working with a shredder and during its manufacture

Lawn roller: description, functions, how to do it yourself

Since the design of a garden shredder includes piercing and cutting elements, set in rapid motion by a powerful engine, in order to avoid injury, it is worth following the safety rules when working with it:

- Before starting work, it is necessary to protect the face, eyes and head from chips that can fly in different directions during the grinding process. This point is especially relevant when processing large branches. For this, it is recommended to wear special goggles, a hat and a mask. Also, you need to choose protective gloves in size so that they do not fall off your hands during loading of raw materials.

- The garden shredder should be placed on a level surface to avoid tipping over during the work process. It is strictly forbidden to work with electric grass cutters in rainy and windy weather.

- You can push and correct the branches in the funnel of the device only with a special pusher, but not with your hands.

- Break branches should be of the recommended thickness, which will help to avoid equipment breakdown.

- Before loading the grass into the shredder, it is recommended to first sort it out, removing foreign objects from it (stones, metal, glass, plastic, etc.).

- It is recommended to use only fresh branches for crushing. To avoid a short circuit, do not use units with a damaged wire or socket, as well as allow moisture to come into contact with the cable. When refueling the disposer with gasoline, do not use an open fire near it, as well as smoke.

- Before cleaning the device, it is imperative to wait until all units come to a complete stop and disconnect the shredder from the power supply.

A garden shredder is an indispensable and useful thing for gardeners and farmers, which can be easily purchased at the markets or made with your own hands. The main thing is to observe safety precautions and properly maintain the unit.

Do you need a shredder?

Undoubtedly, because grass for chickens is the basis of the diet, as strange as it may sound. For owls, for example, it is important to eat rodents whole, although they will regurgitate wool and bones. This is how their digestive system works. The same goes for chickens: they can be fed with special feed, grain, etc., but nothing can replace them with those nutrients that are in fresh living grass.

However, compared to those owls, chickens need to consume the herb they need every day. How human will it be to cut plants by hand every day? Hardly a lot. That is why a grass chopper is needed.Moreover, chopped up plants are much more pleasant for chicks: it is easier to peck on ready-made food than trying to pluck leaves from a long stem.

Also, a grass chopper for chickens will be useful if there are a lot of chickens themselves. The daily cutting of plants is depressing, and if you need to do this on an especially large scale (after all, chickens eat a lot), then you cannot do without a suitable tool.