Growing mushrooms on your own plot is not only exciting, but also a profitable business. If you're new to mushroom farming, try starting with oyster mushrooms. These are unpretentious, but very prolific mushrooms. Someone grows them for themselves, and someone was able to make a profitable business out of oyster mushrooms. Indeed, with 1 kg of mycelium, up to 4 kg of mushrooms are obtained!

Oyster mushrooms

There are two ways to grow oyster mushrooms: intensive and extensive.

Conditions for cultivating a plant on your own plantation

As we noted earlier, oyster mushroom is a valuable mushroom and is often found in city markets. And if amateur mushroom pickers are used to harvesting, getting out into the forest during the natural period of ripening of the fruits of the crop, then agronomists who own the business of intensive mushroom cultivation have the opportunity to produce the product throughout the year.

For the successful production of oyster mushrooms (from the Latin Pleurotus ostreatus), it is necessary to equip a special plantation, the conditions of which will fully correspond to the natural habitat of the plant. This business has many advantages, as well as costs. The acquisition of specialized equipment requires a lot of investments, however, the result is not long in coming - a businessman collects a high-quality harvest all year round, establishes wholesale sales, thereby making a good profit.

You can also grow the mushroom on a less industrial scale - anyone who wants an agronomist or summer resident can do this.

So where do you start?

Let's move on to a detailed study of each of the stages of cultivation of the mushroom we are considering.

Life hack! Read the rest of the article and you will learn how to grow at home to always stay with your harvest. My experience for 15 years.

Sterility

If you plan to grow the product not only for your own table, but also for sale, read the conditions for preparing the premises. This can be a greenhouse, a cellar, or a covered extension.

Certainly, some agronomists manage to grow oyster mushrooms on balconies, but this is fraught with certain difficulties. In particular, it is very difficult to maintain an ideal climate there.

But if you agree to donate a piece of the apartment, then if you wish, it can be refurbished and specialized. But the cultivation of mushrooms in the room is not recommended, as it can negatively affect the state of health.

The main thing to remember is that the guarantee of a rich and bountiful harvest is cleanliness. All surfaces, including the floor and walls, must be treated with a bleach solution prepared in accordance with the instructions, and then whitewashed with lime with the addition of copper sulfate.

If the basement where you are planning to organize the beds is prone to flooding, nothing sensible will come of it - dampness provokes the appearance of mold.

The requirements for environmental humidity are strictly observed, while it is important to provide the oyster mushrooms with air circulation in order to prevent overheating of the beds.

When choosing lighting, give preference to fluorescent lamps - incandescent lamps can disrupt the optimal temperature regime.

Preparing the substrate for the substrate

The most used raw material for mushroom substrate is cereal straw.

Dry stems are best suited for successful fermentation, and although some farmers prefer the tops of garden crops, sawdust, etc. to straw, we will consider how to prepare the substrate on straw, since even capricious champignons grow in it. The main condition is that the raw materials must be of high quality, fresh, dry enough, without signs of mold. Good straw has an even golden color and a pleasant smell.

Basic manipulations in the preparation of the "base" ingredient:

- Grinding dry plants.

- Soaking in water.

It is important that the straws are the same size, preferably short, about 5-10 centimeters. Experienced mushroom growers explain the requirement by the fact that small pieces of hay are easier to handle. In addition, there will be fewer gaps in the substrate that prevent the mycelium from developing.

After the raw material has been crushed, it must be soaked. Hay is placed in large containers, filled with clean water without impurities. The future substrate must absorb moisture, the excess liquid is squeezed out after. In industrial-scale factories, special belts are installed, with the help of which the hay is passed between two rollers. Everyone remembers the Soviet washing machines and their spinning principle - this system works identically. Alternative methods are using a jack or the hands of workers. The goal is to achieve optimal humidity (no less than 60 and no more than 70 percent).

Since not every mushroom grower has special equipment, the moisture level can be checked manually. To do this, you need to take a little of the substrate in your hand and squeeze it. If water is squeezed out and dripping from the stems, there is a lot of liquid. Ideally, when droplets come out of the raw material, but do not pour onto the floor.

It is important to ensure that the straw is not in the water for more than a few hours, because in this way the raw material is not only saturated with moisture and cleansed of pests, but also loses useful microelements and nutrients.

Heat treatment of the substrate

After completing the described manipulations, the substrate must be thermally treated. The fact is that the natural growth of oyster mushrooms in nature is impossible on straw. The reason is microorganisms living inside dry stems. And in order to get rid of these microorganisms in production, it is imperative to treat the straw with high temperatures, for example, using sterilization.

The procedure is carried out in special machines, with the setting of a certain heat and pressure (+ 115-120 degrees, 1.5 atmospheres). Processing takes approximately 120-180 minutes. After that, the substrate is artificially cooled to room temperature and mushroom mycelium can be populated into it. The method is relevant for large industries, since the purchase of equipment requires a round sum of money.

Home and just small farms with oyster mushrooms resort to a non-sterile method of heat treatment, namely fermentation. For this, the substrate is simultaneously heated and ventilated:

- Raw materials are heated to 70 degrees, this level of heat is maintained for 10-12 hours.

- After the specified time, the temperature slowly drops to 40 degrees (the process takes 2-3 days).

The main regulator of indicators is hot air and steam. Throughout the entire process, the so-called fermentation takes place in the straw (the destruction of harmful microorganisms and the fermentation of the raw material's own enzymes). After that, the substrate is cooled to 25 degrees.

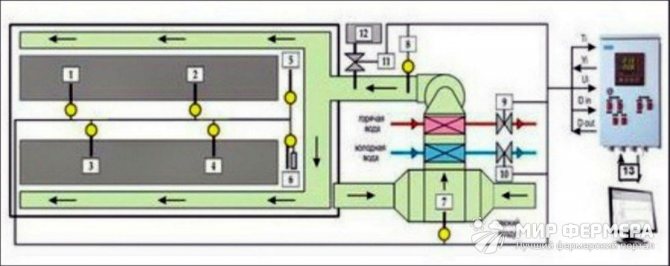

It is recommended to ferment raw materials in a previously prepared container or special, ventilated chambers. The latter should be equipped with ventilation systems, a steam generator and grates on which the substrate is laid. The next step is to populate the mycelium into the substrate.

For those who plan to equip chambers for oyster mushroom cultivation:

- The recommended floor and ceiling covering of the room is vapor-tight, such as a primer.

- The optimal room size is 2 to 5 meters long.

- Mandatory equipment - racks with metal or lattice shelves.

- Air duct, fan, steam generator, several vents with air intake flaps.

As soon as the room is ready, the substrate can be laid on the racks or grates. The raw material does not need to be rammed, it is only important to observe the height of the "piles" - about 1.5 - 2 meters. After that, the bottom steam supply begins - in this way the substrate not only heats up on its own, but is also "fed" by the heat from below. This speeds up the fermentation process, which means that the soil for oyster mushrooms will be ready in a few days.

It should be noted that foreign farmers prefer xerothermal treatment of the substrate. For this, a special, stainless steel container, called a xerothermal chamber, is used. Initially, the straw is crushed into 1.5 - 2 centimeters in size, after which the raw materials are fed into a container. The responsible specialist starts the steam generator and controls the oxygen supply, treating the substrate for an hour and a half. After finishing the treatment, it remains only to moisten the artificial soil by adding fudnazole and sodium hypochlorite to its composition. Done. You can relocate the mycelium to a favorable environment for it. The method is only suitable for a homogeneous, clean substrate. If the mycelium base consists of several ingredients, the result may not be worth the cost. It is also crucial to maintain the sterility of the room, instruments and air. The described procedure is widespread outside our country, however, domestic manufacturers are trying to keep up, gradually adopting the experience of foreign specialists.

Method 2

Another proven method of heat treatment of the substrate is the use of a feed steamer. The container is filled with raw materials, filled with hot water (approximately 80 degrees), after which it is filled with hot steam, which does not allow the liquid to cool down. The recommended time for keeping warm in the feed steamer is 3-4 hours.

A similar heat treatment system is also used at home, but instead of special containers, agronomists use ordinary metal tanks with hot water. Boiling water softens the substrate, destroys pests and converts microelements useful for fungi.

Steam pasteurization of the substrate

Garden mycelium

Oyster mushrooms can be grown both in an enclosed space and in an open area - on stumps. The second option is the least expensive, but relevant if you do not set a goal to make money on the sale of products. But collecting a dozen or two baskets for yourself will be quite successful.

This is an extremely simple way. You will need several chocks - linden, aspen or willow, mycelium or cleaning (the lower parts of the legs with soil) from eaten mushrooms, mixed with a wet base.

The stumps must be thoroughly watered, cut, filled with the seeded mixture, and then left in the garden, in the shade. All that remains is to be patient and wait for the disputes to sprout.

Planting mycelium

After heat treatment of artificial soil for oyster mushrooms, it is necessary to inoculate the mycelium in a short time. The ideal substrate temperature for planting is 21-29 degrees, humidity is 65 - 80 percent. In case of deviations from the presented indicators, there is a high probability of death of the mushroom rhizome.

The process consists of several stages:

- The day before disembarkation, the mycelium is removed from the chamber and placed in an environment with room temperature. It is important that the temperatures of the mycelium and the substrate are the same at the time of inoculation.

- The planting material itself is poured into a sterile container, after which it is crushed by hand.The specialist responsible for the process is required to wear medical gloves, in addition, to disinfect his hands during work. To do this, you should stock up on sodium hypochlorite solution.

- After the mycelium is crushed, it is immediately mixed with the substrate. You can cover the mycelium in layers or evenly. The total mass in relation to soil is 4-5 percent to 100.

It is noteworthy that on some plantations non-standard methods of forming mushroom beds are used, for example, the total planting mass can be in the form of walls. For this, the formwork familiar to builders is used. Foreign colleagues, on the other hand, increase yields by reducing the thickness of the substrate.

Foreign novelty

The so-called Canadian method has been highly appreciated by mushroom growers in recent years. Its essence lies in the germination of the finished mycelium in a special container. You just need to purchase a mycelium, open the box, sprinkle with the liquid that comes with the kit, and install in the designated place.

If you clearly followed the description, then from one package you can easily get up to 5 kg of oyster mushrooms.

Rooms suitable for cultivation

Thinking about how to grow oyster mushrooms, everyone who wants to try their hand should be aware that it is necessary to find a suitable room for the plantation.

The space must meet certain requirements.

So, the practice of successful mushroom farms shows that the following are suitable for successful production:

- Grocery storage;

- Underground bunkers or bomb shelters;

- Basements of residential buildings or technical buildings;

- Wine cellars;

- Greenhouses with good thermal insulation and shaded cover;

- Unused stables or cowsheds;

- Tunnels;

- Agricultural hangars.

Racks or places for mushroom blocks are equipped along the perimeter of the walls - the location depends on the individual preferences of the farmer (you can build walls, hang, put blocks on top of each other).

The most convenient and compact are the sections that resemble an open cabinet. Each shelf is equipped with a special pin that fixes the substrate. If necessary, the pile simply rotates, but does not budge - it is convenient not only to grow, but also to harvest.

The temperature in the room should not rise above 25 degrees Celsius, and this is without taking into account artificial influences. It is very important to maintain a certain microclimate, since the mushroom mycelium can quickly die, and the fruits that have already erupted can deteriorate. Cold is also harmful to oyster mushrooms, so unheated rooms can be used for growing crops exclusively in the warm season or where a warm climate prevails.

It is imperative to install electric lighting on the plantation - the oyster mushroom needs at least dim, but still light.

Not to mention the agronomists who control the process of fruit growth.

With successful, proper business management, one cycle of maturation of oyster mushrooms takes 7-8 weeks. The shelf life of one batch of substrate with mycelium is up to three harvests. Experienced growers recommend dwelling on the second wave of fruiting, since all subsequent ones are declining and may not be worth the effort.

Under what conditions does oyster mushroom develop best?

In order to get a rich harvest, it is necessary to provide certain conditions, as well as proper care. Pay attention to the recommendations, adherence to which will simplify the process and improve the result:

- The ideal constant air temperature on the plantation is 23-24 degrees with a plus sign.

- Bright light is contraindicated for mushrooms.

- A favorable percentage of indoor air humidity is 75-85 units.

Approximately 36-48 hours after the transfer of the mycelium to the substrate, the first test of the growth dynamics is carried out. The seeded soil acquires a light white bloom due to the fact that the mycelium is actively developing.At this stage, it is important to avoid the formation of a crust on the surface - the so-called stroma. The phenomenon can cause the death of the crop, or, at least, a tangible deterioration in the yield.

You should also check the substrate for infection with fungus or bacteria - the presence of spots on the "soil", an unpleasant odor, and strange growths may indicate a lesion. If damaged blocks are found on the plantation, they must be urgently isolated and disposed of - this will save the entire batch of mycelium from death.

Useful Tips

A good harvest of mushrooms can only be obtained from sowing quality mycelium. To achieve success in the removal of mycelium and commercial cultivation of mushrooms, certain rules must be followed:

The best substrate is hardwood sawdust.- The sawdust should be white or yellowish.

- The smell of the base of the substrate should be fresh.

- When transporting mycelium, it is necessary to maintain a humidity of 30-45%.

- Inside the mushroom blocks, temperature and humidity standards must also be observed.

- The optimal amount of mycelium enclosure in one 35 * 75 block is about 300 grams.

- The entire production cycle must be carried out in compliance with the rules of sanitation.

- The technology for making the mycelium must be observed.

Mushroom growing is a rather troublesome business. Requires adherence to certain rules, a lot of time and diligence. But no special education, expensive equipment and materials are required. Does not require constant presence and maintenance... At the same time, the probability of obtaining a quality product is much higher.

Harvesting and storage

The fruiting period of oyster mushrooms is 6-7 days from the moment the rudiments appear from the upper layers of the substrate. This is enough time for the small embryos to transform into ripe, edible fruiting bodies. The culture develops in so-called intergrowths, each of which consists of already mature and still young mushrooms.

When collecting, it is customary to twist all the fruits at the same time - it makes no sense to wait until the babies reach large sizes, since already mature representatives will begin to deteriorate. If you leave tiny mushrooms on the splice, collecting only large ones, their growth will stop due to damage to the "base".

As we noted earlier, oyster mushroom can bear fruit in several waves, but only the first two can be considered productive. The first ripening stream brings about 65-70 percent of the crop to the agronomist, the second 20-25 percent. It makes no sense to wait for the third, its percentage does not exceed 10 units.

From the above, we can conclude that one technological cycle in production lasts no longer than 2.5 months. Ripe mushrooms are carefully cut from the soil, freed from debris, and then placed in boxes / boxes / baskets. In order for the product not to lose its presentation, it is necessary to minimize the number of movements of mushroom fruits from container to container.

To preserve the weight of oyster mushrooms, avoiding the natural drying process, polyethylene is used. The crop is wrapped in foil and transported to the place of sale.

As for the storage of fresh mushrooms, its period should not exceed 6-7 days at an air temperature of no higher than 6 degrees Celsius. If the room is hot, the food will go bad after 24 hours. The exception is freezers, in which the shelf life is increased to 1.5 - 2 months.

Every agronomist who grows oyster mushrooms for the purpose of sale must follow the capital standards. A quality product differs in the following indicators:

- The body of the mushroom should have a pleasant smell, firm pulp and clean skin.

- The optimal size of the cap of the fruit of the 1st grade is from 5 to 12 centimeters, the legs are up to 10.

It is strictly forbidden to spread or consume damaged, watery, friable and musty fruit bodies.

Life hack! If you do not have your own premises, you can read the article - Growing oyster mushrooms on stumps on the site.

Fruiting process

Growing oyster mushrooms

The whitened substrate must be kept in the "native" bag for another 5-6 days after ripening, if this bag is sent for fruiting. During this period, it will finally mature, become "monolithic", will be as dense as possible.

To activate the beginning of the crop formation, bags with completely processed substrate mycelium are kept at + 3 ... 5 ° С for another three days. To enable the mushroom fruiting body to grow, it will need room to grow. To create it, holes 3-5 cm in diameter are cut out in polyethylene (one per square meter). The packages are moved to an underground room in temperature conditions of + 10 ... 16 ° С. Here they are installed at a distance of at least 30-40 cm from each other, always vertically. To make it more convenient to water the mushroom "plantation", the bags are placed with ribbons in three rows with a 70 cm gap between them.

Advice! If you are the happy owner of a high basement, then you can also place bags with future mushrooms on additional shelves located along the walls. Such placement will increase the used area, and hence the mushroom yield.

How to complete the technological cycle by preparing the premises for growing a new batch

After harvesting is complete, it is necessary to clean the plantation of the used substrate and disinfect the premises - only then can a new substrate with mycelium be laid. Pay attention to a number of recommended pest control measures:

- Remove unnecessary raw materials from shelving or deck.

- Get rid of the remaining substrate with a household vacuum cleaner.

- Treat the room with formaldehyde (by mixing liquid formalin with bleach in enamel tanks). The containers with the mixture must be left open, closing the room with them for at least 36 hours.

- After several days, remove the tanks with the connection and thoroughly ventilate the room.

- Prepare a formalin solution (200-250 grams per 10 liters of clean water). Repeat the treatment, followed by airing.

- Clean the shelves with sodium hypochlorite (1%).

Check the plantation for insects or other pests. If none are found, you can lay a new batch of substrate.

We looked at how to grow oyster mushrooms at home, as well as in a production environment.

Keep in mind that the growing season of the crop is accompanied by the appearance of fungal spores in the air, which can be dangerous for people prone to allergic reactions. To avoid trouble, use respirators and cultivate only special strains of fungi.