Residents of country houses, builders and summer residents, in the absence of a central water supply system in their personal plot, are forced to solve the water supply problem on their own. To feel comfortable away from the benefits of civilization, underground sources are used. It is possible to provide yourself, a garden and a household with water if you build a well with your own hands.

Water well in the yard of the house

It is very important to choose the right place for the hydraulic structure and dig it to the optimum depth. Then the composition and volume of water will be acceptable to use it for domestic needs and drinking. In some regions of the Russian Federation, permission from local authorities is required for the construction of wells up to the first water-bearing level.

How to choose a place for a well in the country

In order for the water to meet sanitary and hygienic requirements, whether it is a well in a country house or a personal plot, the place should not be near objects that pollute the soil and air:

- gutters;

- cesspools;

- sheds for livestock;

- storage facilities for fertilizers, chemicals;

- highways.

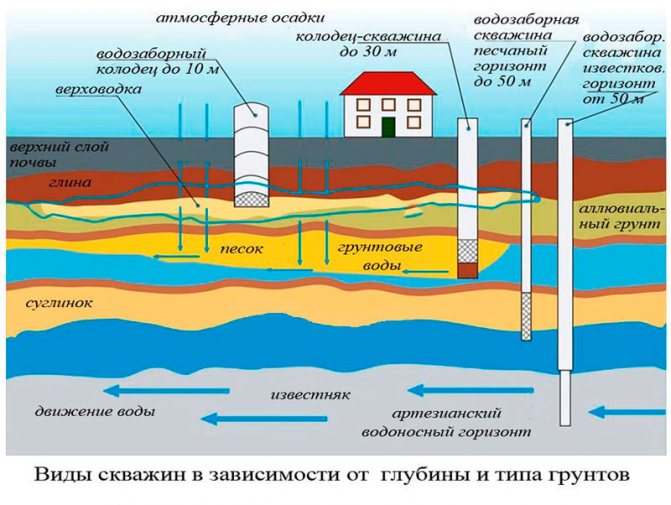

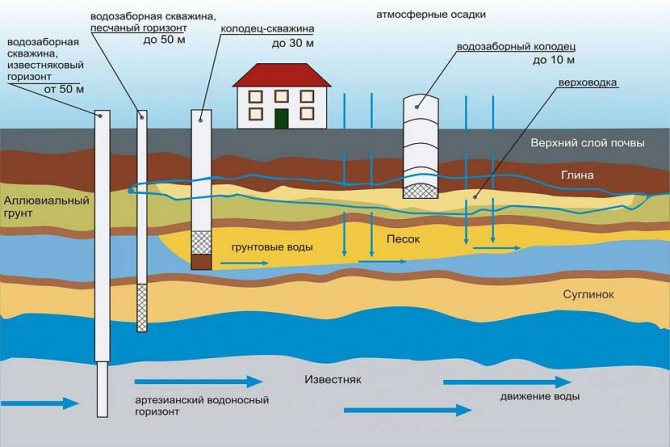

The wells are filled with groundwater located at a depth of 8-30 meters. This is the first aquifer fed by precipitation, melted snow, rivers, lakes, and reservoirs. Therefore, it is so important that the environment around is clean.

It is recommended to choose a place for digging a well according to folk signs indicating dampness of the soil:

- hygrophilous plants grow well;

- morning fog gathers;

- mosquitoes and midges curl;

- a pot dug to a depth of 1-1.5 m with dried broken brick becomes heavier due to the absorption of water from the ground.

From ancient times to the present day they have been looking for underground sources by dowsing.

Open way of digging

In this case, we dig wells to the full depth, right up to burrowing into the aquifer, and only after that we start installing the casing rings. Such a technological method is distinguished by the danger of collapse of the walls of the mine with all the ensuing consequences for a person. Therefore, the open technology should be used exclusively on dense soils - clayey or compacted gravel and sand.

After installing the casing elements, the seams should be sealed to prevent the ingress of contaminated water from the upper layers of the soil - "top water".

The advantage of the open digging method is that there is no need to constantly keep lifting and erection equipment at the work site to install the rings. The crane is ordered only at the final stage of work, for the one-time installation of all concrete rings in the mine.

The best time to dig a well

The groundwater level changes throughout the year. Fluctuations in the depth of the liquid reach 2 m. The most suitable season for the construction of a well is after a prolonged drought in late summer or in the second half of winter, when the flow of precipitation into the soil is minimal. The filling of underground sources decreases naturally.

If you dig a well with your own hands after rains or in the off-season, it is possible that the water will go away in a couple of months and the mine will become empty.

The time for digging is chosen depending on the type of soil. Clay soils freeze with the arrival of winter, the water in the capillaries turns into ice. Such land is very difficult to grind, it is easier to cultivate it in the warm season.Sands and sandy loams remain loose despite the frost. The well can be dug both in summer and winter.

Mounting rings in winter

If there are difficulties in removing the upper frozen soil layer, specialized equipment can be involved for this work. Below the freezing depth, which reaches 0.7-1.2 m in the European part of the country, the sands are already quite loose and accessible for processing.

Another argument in favor of the winter construction of the well is the prices for earthworks. They are significantly lower than in summer, when demand increases.

A team of three people digs a mine in 3-4 days. It has equipment and well-established technology. If you work alone, it will take much longer. Sometimes it is weeks or even months - you need to select several cubes of the breed. The work is complicated by precipitation, soil erosion and possible wall collapse. It is necessary to arrange the structure in the right way so that you do not have to clean the bottom again and take out dozens of buckets of spilled soil.

Types of blind area for a well

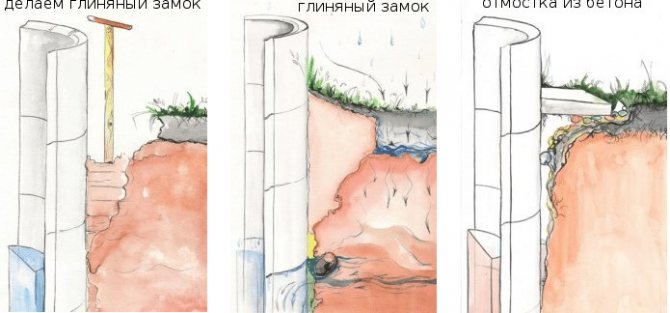

It was the turn of the construction of a blind area around the well. They arrange a blind area of concrete, clay, or make a so-called soft blind area. Remember that the blind area must be done, otherwise, in the spring, when the soil swells, dirt will fall into the barrel of the well.

Traditionally, the blind area is made of clay (clay castle). Soil is dug up to a depth of 2 meters around the rings, and clay is poured in its place. Clay needs to be tamped thoroughly. Above the clay castle is protected with a layer of gravel or sand. For three years, the rings will settle (shrinkage), and the clay layer will have to be tamped in the spring. The quality of the blind area is checked by the purity of the water in the well.

A soft blind area is made of sand and a waterproofing film. To a depth slightly more than the depth of freezing of the soil, the earth is selected and sand is filled up. The sand is compacted, then covered with a film. The edge of the waterproofing film is put on the upper ring of the well barrel, carefully pressed and fixed with a metal tape. A layer of sand is covered with gravel, decorative stone, and lawn grass is planted.

Types of wells

Man began to use man-made wells with the beginning of a settled life about 7 thousand years ago. They were deep pits lined with wood or stone from the inside. Having settled in a new place, people first of all dug up a source of water for themselves and animals. Farming, especially in warm countries, cannot be imagined without irrigation and a system of canals.

Wells differ in depth and method of water extraction:

- Russian. A bucket was lowered into a shaft made of logs with the help of a gate. To prevent it from floating on the surface, a weight was attached to the edge of the container. From above, the source was closed with a well house from the ingress of debris.

- Shaduf. In ancient Egypt, it was used to irrigate fields. The water was lifted by a lever mechanism. Today in the countries of Africa and Asia, similar structures are still found.

- Archimedes' screw well. Water is extracted by a mechanism that drives a donkey walking in a circle.

- Abyssinian. A pipe with a diameter of 25-63 mm and a surface pump are installed in a narrow well drilled to the underground channel. To filter water, the end of the water conduit is equipped with a sieve tip.

The most common designs of wells in homestead and summer cottages are concrete rings submerged in the ground. The depth of the mines reaches 2-18 meters. The bottom is covered with a layer of sand, pebbles and rubble, which cleanse the ground water from impurities.

Concrete ring well

Concrete rings are produced in various sizes:

- inner diameter - 70-200 mm;

- height - 290-890 mm.

For water wells, structures with a diameter of 1000 mm and a height of 890 cm are used. They are installed one on top of the other. For a tight fit, the rim of the rings is formed in the form of a lock. The volume of one element is 0.23 m³.For home construction, 8-12 products are most often enough.

Photo tips how to make a well

Read here Construction of a fence made of corrugated board: the best ideas for a summer cottage, garden or house (130 photos and videos)

Did you like the article?

0

Well shaft type

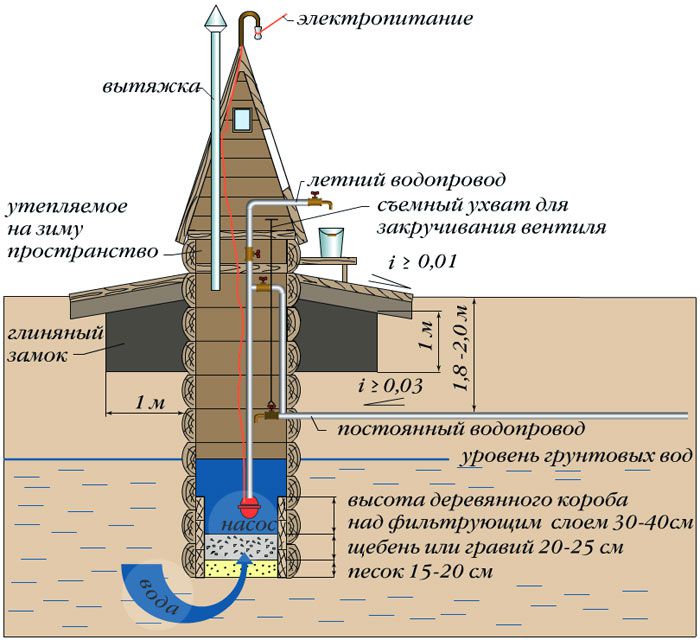

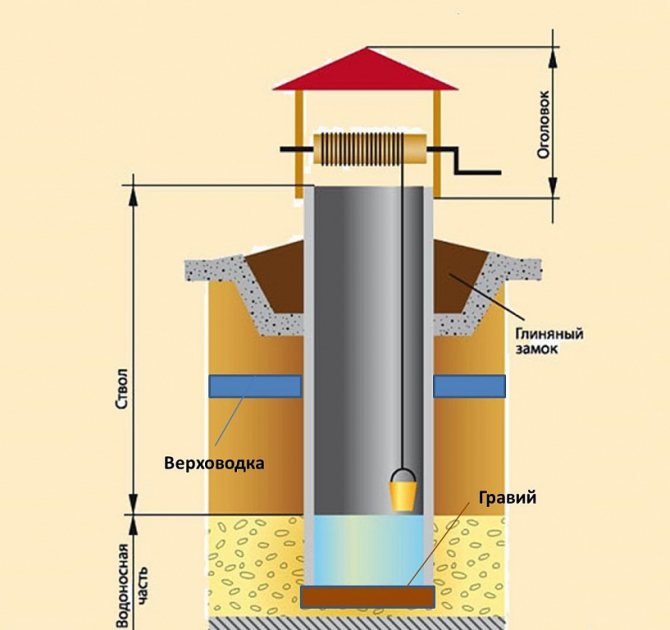

The well consists of a water intake shaft, a shaft and a head that rises above the ground.

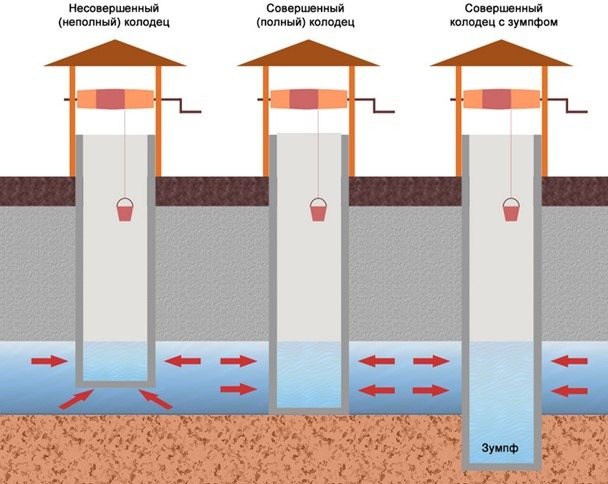

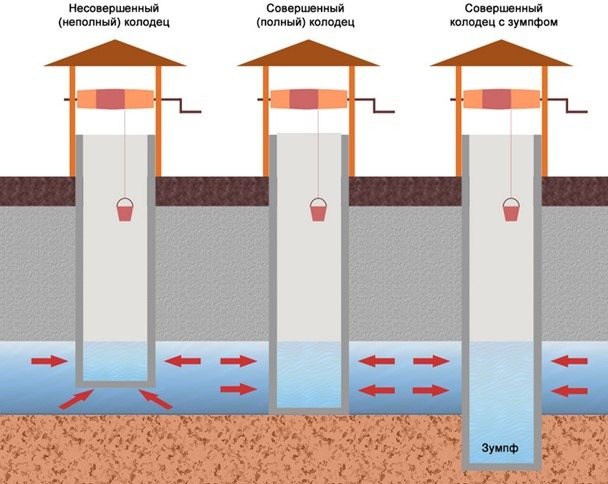

There are three types of well shafts:

- imperfect - the trunk is lowered to the upper boundary of the waterproof layer, filled through the side surfaces and the lower opening;

- perfect - the bottom of the mine rests on the underlying clay layer, water flows only through the walls;

- perfect with a sump - the barrel is deepened into a water-resistant layer to create an additional reservoir.

If you improve the well with your own hands - arrange an expansion below the static water level, a kind of "tent" with a supply of liquid is formed.

The simplest and most widespread mine design in individual construction is an imperfect one. This is an inexpensive option that provides a daily water requirement for household needs.

Important. An increase in the diameter or depth of the structure leads to an increase in labor costs and material consumption, which is unjustified in a suburban area.

How to stain an oak

One of the most common materials used in the installation of wooden wells is oak logs. This is due to the fact that they are able to serve for many years, especially if properly prepared. But there is also one serious drawback here.

Oak gives the water a bitter taste. Over time, the taste disappears, but for this you need to wait a few years. This can be corrected, but it is necessary to carry out the staining procedure. There is a staining technology, which we will now introduce.

First you need to remove the bark and knots. The logs are cut to the required dimensions, taking into account the future dimensions of the well. After that, it is necessary to adjust the frame, each log is numbered, which in the future will greatly facilitate the process of arranging the well.

After that, it is necessary to lower the workpieces into the water, this can be done in a lake or other body of water, but it is a prerequisite that the water is running. They are here for 2 years, after which we take out the logs and dry them under a canopy.

When the material is completely dry, we proceed to the next stage - dig and mount the mine. Despite the fact that the staining procedure takes a lot of time, it is worth it, since the water from such a well will not have a bitter taste, and the structure itself can serve much longer.

Materials for the construction of wells

In the private sector, the following materials are used to form a wellbore:

- Wood. A blockhouse made of logs is immersed in the shaft, creating the necessary support for the walls. Water seeps through the gaps and the bottom. The lower part is made of beech, bog oak, ash, elm. These breeds do not emit tannins or tar substances. The upper crowns are made of pine, larch, cedar. They are not afraid of moisture, do not rot, but are rich in resin.

- Natural stone or brick. Wells made of these materials are distinguished by their durability and strength. The construction of mines is long and laborious, but the water in them is clean, without impurities.

- Concrete. The barrel is assembled from prefabricated rings or made from a monolith. In the first case, special attention must be paid to sealing the joints, otherwise contaminated surface drains will get into the well.

The top of the structure is protected from precipitation, dust and animals by well houses with a cover. They are made from wood, stone, concrete. Facing with decorative materials.

Important. Often, a well in a dacha serves as a bright art object that attracts everyone's attention.

Bottom filter

The bottom filter protects the water from contamination by rising rock particles.It is arranged from clean, washed materials - quartz sand, pebbles, gravel, crushed stone.

First, smaller fractions are poured, then large ones:

- sand - 15-30 cm;

- gravel - 15-30 cm;

- river pebbles - 15-30 cm.

The higher the layer height, the better the cleaning. If the bottom is liquefied and water comes in quickly, first put wooden boards, leaving gaps, then filter materials.

Between the layers, to improve the organoleptic properties of water and neutralize toxic substances, it is recommended to fill in a small amount of shungite, zeolite or jadeite. These are natural minerals that people have used for healing since ancient times.

On quicksands, backfilling is mandatory, since the well will quickly clog up and stop functioning. But the layers are laid in the opposite order - first large, then small fractions. In this case, heavy stones impede the movement of sand in the underground channel. A shield made of oak, aspen, larch or stainless steel should be placed on the bottom as a base.

The bottom filters are regularly cleaned and replaced with fresh ones. Otherwise, instead of good, they can do harm.

Important. Regardless of the presence of stone materials in the well, it is recommended to additionally prepare drinking water - filter and boil.

Arrangement of the bottom in the well

In order for the water in the well structure to always be clean, it is necessary to form a so-called bottom filter at the bottom. To do this, crushed stone or gravel of a coarse fraction (40 mm) with a layer thickness of 15-20 cm is poured onto the bottom, and on top of it is crushed stone of the middle fraction (10-20 mm) with a layer of 20-40 cm.

Some old and experienced craftsmen recommend first laying a wooden platform from boards 30-50 mm thick on the bottom. And already on it to form a bottom filter. This will provide more free passage of water, since there will be free space between the wooden platform and the bottom of the well.

The bottom of the well is covered with gravel or rubble Source

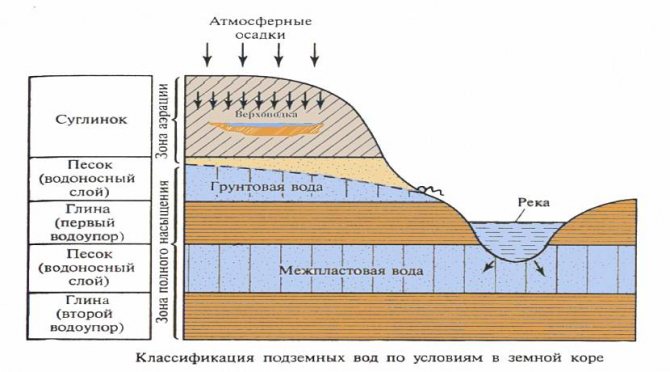

Definition of an aquifer

When digging a well, the question arises how deep you need to dive if water has already begun to seep through the walls of the shaft. To find out where to stop, it is worth examining all the layers passed during the digging.

The top layer is fertile soil. Its thickness is 25-40 cm. Further, sedimentary rocks, sand and clay, which is a water seal, alternate.

Underground springs make their way between water-resistant strata. The one closest to the surface is the top water, which consists of leaked sediments, melt water and accidental runoff. It is not suitable for domestic needs, it is too dirty, and the level is unstable, depending on the weather.

When constructing a well, they try to get to the second or third aquifer. Having passed through the thickness of the soil, the water is purified and becomes usable.

When digging, you need to stop in time - there is a danger to pass the aquifer and go deeper into a thick layer of clay. It is also possible for the mine to sink over time, which will lead to blockage of the water flow path. You need to navigate the neighboring hydraulic structures in order to "catch" the moment and not make a mistake.

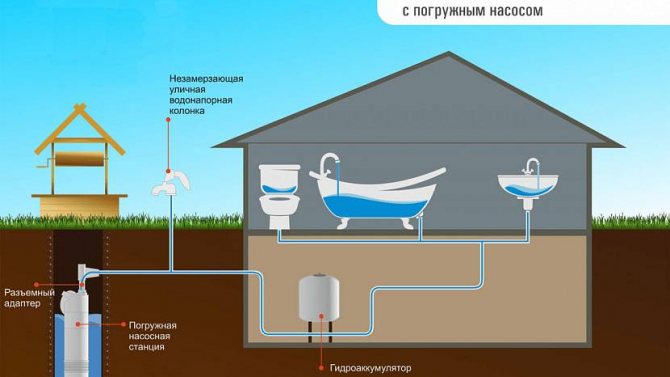

Service recommendations + video

The fact that the well is dug down to the aquifer of the soil does not mean that the water will always remain clean. It needs to be cleaned periodically. If there is a filter in the system, it must be cleaned in accordance with the manufacturer's regulations. Fine filtration stations have replaceable cartridges that must be replaced.

But the well itself will have to be cleaned. Over time, debris gets into it, bacteria settle, and soil particles enter. The bottom is silted up, the water becomes cloudy, it smells unpleasant, and you can't drink it. Mud pumps are used for cleaning. This should be done every three years.If the well is dug in sandy soil, the procedure will have to be repeated annually. All cleaning work can also be carried out in-house.

Construction of a well from concrete rings

Before making a well with your own hands from concrete rings, determine the type of soil. The method of construction depends on this characteristic - open or closed.

Open way

It is used on dense clay soils that keep their shape well. When digging mines, the walls do not crumble, it is possible to carry out work in not such cramped conditions as with a closed method.

The sequence of an open well device:

- They dig a mine to the required depth.

- Upon reaching the aquifer, concrete rings are sequentially installed using a manipulator.

- The joints are held together with rubber gaskets or mortar.

- The sinuses are covered with coarse sand, the upper part is covered with clay to avoid getting inside the verkhovodka.

- From the inside, the rings are fixed with staples, the seams are sealed.

After the end of the work, the walls are cleaned, washed, the water is pumped out several times. A bottom filter is laid, a well house is installed.

If, when digging a mine, the walls suddenly began to crumble, further work is carried out in a closed way.

Closed way

This option is used for the construction of wells on loose or swampy soils that do not retain their shape well. It is more difficult to work in a confined space, using a shovel with a shortened handle. But there is no risk of walls collapse, and the rings can be mounted without the involvement of lifting equipment.

Stages of construction of a well in a closed way:

- Cut off the top layer of the earth.

- Install the first ring.

- Dig the mine from the inside, evenly freeing the space from the ground under the reinforced concrete structure. It sinks under the influence of its own weight.

- After deepening the first ring, the second is installed on it and digging continues.

- Structures are sequentially mounted until reaching the aquifer. The top of the last ring is left above the ground.

- The elements are fastened together with overlays or brackets so that when the ground moves, they do not move relative to each other.

- The seams are sealed, washed, the bottom filter is poured.

To facilitate the installation of a reinforced concrete barrel, the lower end is equipped with a shoe with knives or the edge is shaped like a cone. The arriving water is pumped out with a drainage pump. Mechanical or electrical winches are used for lowering a person into the mine, lifting buckets with the ground and adjusting the position of the ring during installation.

It is almost impossible to cope with the volume of work carried out in a closed way alone. Usually, a team is invited, which is equipped with everything necessary for a quick construction of a well.

Working at depth is associated with risks to health and life. We must not forget about security measures. A helmet is put on the head, the bucket handle is reinforced, strong ropes or cables are used. The reliability of the fasteners and the serviceability of the mechanisms are regularly monitored.

Waterproofing joints

Waterproofing the joints between the rings is a necessary operation that will protect the water from contamination from external drains. It is performed after the installation of the barrel, as well as during the repair of an existing structure, if leaks are noticed.

The methods used for sealing joints:

- a hemp rope is placed in the gap, the top is covered with cement mortar;

- instead of a rope, a bentonite swelling cord is used;

- the joint is sealed with ready-made high-speed hydraulic seals;

- the solution is made on the basis of liquid glass and the seams are filled with it.

Before waterproofing work, the seams are thoroughly cleaned, if necessary, they are moistened. Materials are used as sealants that do not change the composition of water and are harmless to humans.

Safety regulations

Many inexperienced homeowners rarely pay attention to a set of mandatory safety rules.If you do not comply with them, this can lead to disastrous consequences, endangering human health. So, in order to prevent getting various injuries, you should consider the following tips:

Do not start work without a protective helmet on your head. If the bucket breaks off during operation, it will cause serious damage.- Only thick ropes should be used to raise the buckets with soil, and strong ropes should be used to lower the decks.

- If we are talking about digging a mine with a depth of more than 6 meters, then two ropes are fixed on the bucket: the main one and the safety one.

- To reliably insure the worker against ground movements, he must be tied with a rope to the second end, which is securely fixed to something solid.

- If the mine is very deep, be sure to check for gas contamination. For such experiments, you should periodically light a candle. If it goes out immediately, it means that the gas level is very high and it will have to be weathered. In this case, the working installer needs to get out of the mine and, having tied a large blanket to the rope, lower it several times to the bottom. Much of the accumulated gas will escape with the blanket. After that, you can climb back in and continue working.

Subject to these rules and recommendations, you reduce the risk of serious injury or mechanical damage during self-arrangement of a well shaft. Careful implementation of the step-by-step guide will allow you to build a truly beautiful and well-arranged well, which will become an excellent decorative decoration and a good alternative to the city water supply.