Livestock »Pigs

0

2563

Article rating

Pigs are leaders among domestic animals in terms of productivity and unpretentiousness. From one individual, you can get more than a hundred kilograms of good meat, and proper feeding guarantees a greasy layer with high taste. Sows are also considered very prolific among artiodactyls. To get the maximum amount of the final product, the animal must be properly fed. If the farm is large, then an automatic feed should be provided. Pig feeders can be built with your own hands. However, for a good result, high-quality materials and drawings should be used.

Pig Feeders

Requirements for feeding tanks

Before you make a pig feeder with your own hands, you should master the carpentry skill and calculate the drawing of the future design. There are several basic requirements for any feeder:

- availability of food for animals;

- tightness;

- lack of toxic components;

- conformity of materials and consistency of feed.

Building a pig feeder with your own hands is possible without using a standard scheme. Calculations can be done by yourself, which allows you to adjust the container to the size of the barn. It should be borne in mind that the container for feeding must comply with sanitary standards. If the structure is difficult to clean, then some of the old food may start to rot. This will cause illness. Also, such an environment is favorable for worms, worms and other harmful parasites. This should be especially taken into account when building a piglet feeder. Young animals do not have strong immunity, and poor feed can cause an epidemic. To avoid this problem, the container must be thoroughly disinfected every day.

A closed structure must have a ventilation system. If the air circulation inside the container is disturbed, this can cause spoilage of grain feed. High humidity in the absence of ventilation leads to the appearance of mold and mildew.

Artiodactyls have well-developed muscle mass and rarely eat food neatly. The container must stand firmly on the ground. In addition, a do-it-yourself piglet feeder should be equipped with special sills so that food does not fall out on the ground. When the young have eaten the feed from the stall, they begin to pick up the scattered remains. Also, drinkers are often installed near the feeders, so dirt can get into the water.

Types of feeders depending on the products

Diy pig feeder scheme should take into account the characteristics of the feed. If the food takes up a lot of space, then the container should have a large volume. Also, the materials and shape of the container depend on the consistency of the food:

- For dry cereals, medium-sized feeders are suitable. Hopper tightness is not a priority, but grain should not spill out. The best material for such a container is wood. This raw material is environmentally friendly and has the ability to draw out excess moisture, which will not allow the cereals to become damp.

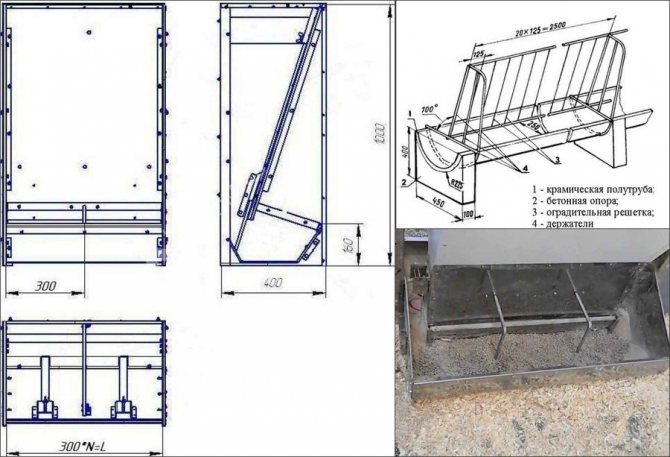

- For hay and grass, it is better to use iron grates and nets. Green food takes up a lot of space and is too light to automatically fill the tray under its own weight.

- Wet mash and liquid substances are best poured into a trough. Due to the viscosity, food can become stuck in the hopper system. The best material for such containers is plastic or metal, as this will keep the feeder from leaking.

Separation of feed for animals of different ages

On a large farm, juveniles and adults should be fed separately. Eating pigs of all ages together can have the following consequences:

- adults can trample piglets;

- bacteria and harmful insects from older pigs can cause diseases of young animals;

- piglets will not get the right amount of feed and will be stunted.

In order for the young to eat well, a separate structure is made for it. The division between the animals takes place by adjusting the sills and sides: in this way, adults will not be able to get to the piglets' feed, and the young will not eat from a common high trough.

The best option would be a do-it-yourself pig feeder, the sides of which are at the chest level of small pigs. This will allow the animals to eat without tilting their heads, which will have a good effect on the development of bone and muscle tissue.

The feed tray should be angled to collect food in one place. To achieve this effect, the rear pillars need to be a few centimeters higher than the front pillars. This design not only simplifies food intake, but also facilitates the process of cleaning containers.

To make the feeder last longer, you can make a nut height adjuster using hinges. To do this, grooves are made in the side walls of the feeder, and the front sheet of plywood should fall to the floor in front of the racks. Self-tapping screws can be used to secure the adjustable board to the desired height.

To prevent young animals from getting into the trough of older pigs, you need to install a ceiling of boards. For adults, this will not be an obstacle, and piglets will not be able to scatter food. To properly cover the pig feeder with boards, you should watch a video or photo from the master classes.

Metal systems

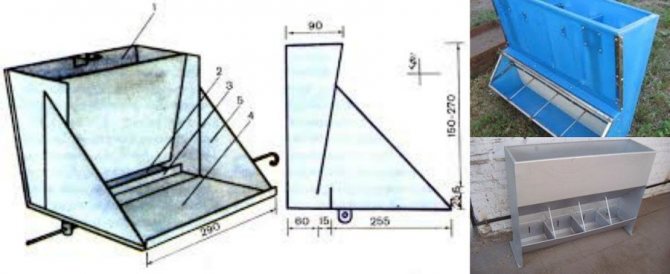

This article presents various drawings of a pig feeder. For example, you can build your own elongated metal nursery. They are made of steel, thin galvanized sheet. The workpiece is bent on the frame using a mallet (with a rubber or wooden striker) or a hammer. It is necessary to make a flanging of the edges so that the animal does not get hurt while eating. Two end pieces provide greater structural stability. They are welded or attached with rivets. To prevent pigs from getting into the feed, several crossbars should be installed with a step of 45-50 cm.

Varieties of feeders depending on the filling method

There are several types of construction, depending on the filling:

- Manual filling. This type includes open trays and troughs. These feeders are suitable for wet mash and liquid. Feeding is done manually by a human. Such designs are easy to make at home.

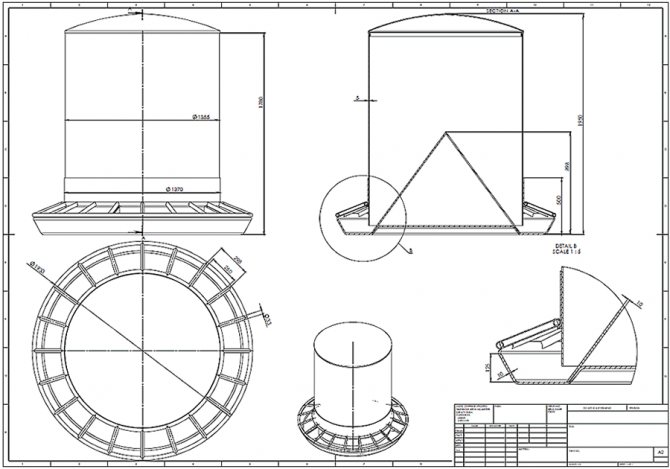

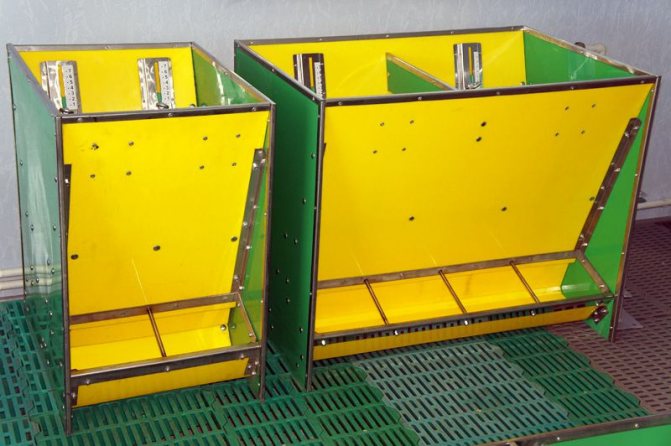

- Automatic filling. This feeding method is used on large farms as it saves physical costs for the owner. Automatic feeders for pigs provide in their design the presence of a hopper into which products are poured. Under its own weight, the food independently regulates the filling of the tray.

The hog hopper is used by farmers to provide the herd with crops or vegetables. The body of the product can be metal or made of wood. People who are well versed in carpentry can build hopper feeders for pigs at home, since the container should be made sealed.

Auto feeders for farm pigs can be bought at the factory or in the store.The company guarantees the quality of the product, but the design itself may not meet the individual requirements of the animals.

Features of the

Industrial feeders are expensive and are mainly purchased for large complexes. Private traders and farmers still try to make them with their own hands, using improvised materials: wood, metal, plastic. It doesn't matter what kind of car feeder and what material you decide to make, it still has to meet certain requirements.

- The feeder should be made of material that will be easy to clean.

- The material should be chosen environmentally friendly.

- The presence of sides will prevent scattering of feed from the trough and will not allow the feeder to be contaminated with waste products.

- Sealed containers will avoid contamination of the environment with wet feed.

- Animals should easily get food from the container, and not interfere with each other's food intake, especially for young animals.

- It is good to use troughs with sloped bottom so that the feed accumulates in one edge. It is convenient for animals and humans.

- You can not choose containers that are traumatic for animals. The design cannot have jags and protrusions.

- The design of an auto feeder should have a decent weight or a convenient fastening system. This will help prevent overturning.

- If there is a large number of livestock, the feeder must be divided into sections.

In addition, the "table" of the animal must have a certain size, they are determined based on the number of animals in the pen and the age and sex group. The requirements for the dimensions of the sections can be seen in the figure.

Plastic bottle feeders

Such feeders are often used to feed young animals during the period of active growth. Plastic compares favorably with wood or metal because it does not leak or corrode. The downside is the short service life.

To make such a container, 10 liter bottles are used. The manufacturing process looks like this:

- the bottle is cut in half;

- the throat is cut off;

- the halves are fixed with construction glue.

This container is suitable for dry food and wet mash. Lack of material costs allows for each generation of piglets to make a new feeder. In a similar way, you can make a drinker for an animal by cutting the bottle across, not along.

Feeders from technical pipes

PVC pipes are often used on farms with large numbers of pigs. The elongated shape of the raw material allows you to make a container with which you can feed a large number of animals.

The pipe must have a diameter of at least 60 cm, otherwise the container will turn out to be too small. The manufacturing process has the following features:

- the pipe is cut in half;

- plugs are installed at the edges of the structure;

- the feeder is attached to the wall.

Such a design requires anchoring to a vertical surface, otherwise the pigs can turn it over. In such a feeder, liquids and wet mashings can be fed, since the material does not allow water to pass through. To avoid leakage, the plugs should be reinforced with construction adhesive. Thus, you can make feeders and drinkers for farm pigs.

Drinking bowls for pigs

In addition to feeders, drinking bowls are required for organizing a pigsty. In the past, farmers used troughs or basins, but the animals constantly knocked them over. This caused the floor to become covered in fetid dirt.

Modern pig drinkers also differ in the type and method of water supply. Livestock breeders buy them in specialized stores or make them themselves.

For your information! In large farms, automatic drinkers for pigs are used.

The most common option is the cup design. It is a container with sides that prevent animals from spilling water.

It is of two types:

- valve - when the pig comes to the drinker, it steps on the pedal. As a result, a mechanism is triggered and water enters the bowl. If the pig moves aside, then the liquid will stop pouring;

- nipple - to get drunk, the pig takes a special nipple into its mouth, from which water comes. The design has a complex mechanism, but it is more economical than the first option.

Both types of piglet drinkers can be made by hand. The valve design is the simplest in execution.

Cylinder feeders

A good pig feeder can be made from a gas bottle. Such designs are distinguished by longevity, thanks to the raw materials. In addition, metal feeders are easier to clean and treat with disinfectants and absorb less chemicals and toxins.

It should be noted that a gas cylinder feeder requires skill in cutting metal. Before work, the cylinder should be left open overnight outdoors. If the container is not ventilated, gas residues may ignite while working on metal. In the morning, the valve should be greased with soapy water. The absence of bubbles indicates that gas has escaped. The cylinder is fixed on the ground, after which you can start cutting the container with a grinder.

Before starting work, you need to apply the markings so that the cut is even. You can get several feeders from one container, so do not neglect the calculations.

The structure is cut along the vertical axis. Each half should be burnt to remove the heavy odor and then can be installed in the barn. Such a feeder weighs a lot, so you need to decide in advance where to place it.

Before making a balloon feeder for pigs, beginners are advised to watch training videos and photos.

How to make a trough yourself

Today, a feeder of any type can be easily picked up in specialized stores. Manufacturers offer a wide range of models from various materials, with any dimensions and design features. But often this type of product is distinguished by its high cost, which does not always suit the buyer. In this case, if you have material, you can make a trough for pigs with your own hands.

Made of wood

A wooden food container is the simplest and most practical option for a feeder. You can do it without even having significant experience in working with wood. Such a device is made as follows:

Wooden trough for piglets

- Two large rectangles are cut out of wide boards of small thickness. Their length is calculated based on the values given above.

- Further, two identical triangles are cut out of the same boards, which will go to the ends.

- All parts are tightly connected to each other using self-tapping screws.

- Additionally, you can also equip the structure with wooden restraints, which are made from a bar and fixed on top of the trough.

- It is advisable to process all joints and cuts with a grinder or sandpaper in order to completely exclude the possibility of injury.

Reference. This shape of the container was not chosen by chance. The angled sides of the trough will make feeding more comfortable and will also make it easier to clean the trough of feed residues.

Made of plastic

To make a plastic version of a container for feeding a farm, you will need a free barrel or other bulky plastic product. From one such container, you can make several convenient and practical feeders at once. They are done according to the following algorithm:

- Using a marker or pencil, divide the barrel lengthwise into 2-4 parts. The number of parts directly depends on the volume of the container.

- Using the finished markings, we cut the plastic container with an electric jigsaw or manually. The main thing is to stick to the lines exactly. All sharp corners at the end of cutting are rounded off with the same jigsaw.

- For stability along or across the resulting feeder, wooden blocks of the same size are fixed with self-tapping screws. They will prevent rollover.

- Further, all edges and irregularities are carefully sanded to prevent injury.

Attention! Even before carrying out all the work, it is worth making sure that the plastic barrel has not been used to store toxic substances. If poisonous liquids were still contained in the container, you should not use it.

From a gas cylinder

Gas bottle

A used gas cylinder will also be the optimal base for the trough. The metal container obtained from it can serve for many decades. The whole process of making a feeder in this case fits into the following plan:

- Possible gas residues are vented from the old cylinder. To do this, the valve is unscrewed until it stops, and the outlet is lubricated with water and soap dissolved in it. Further actions can be carried out only when the applied soap solution stops foaming.

- In the cylinder laid to one side, the valve is cut off to the very body. Such a procedure is carried out with an ordinary metal file, and the place of cutting itself is continuously poured with water from a hose to prevent the appearance of sparks.

- An abundant amount of water is poured into the hole obtained after cutting, and the container itself is carefully chatted for some time. This will remove liquid gas residues.

- On the cylinder, using a marker, lines are marked along which the grinder will be cut. The simplest option is to cut the balloon in half lengthwise and get two identical containers.

- The resulting trough is placed on a previously prepared stand. It can be made from rebar, iron corners, or a solid sheet of iron.

It is better to install the trough on the stand at an angle. This will make it easier for the pigs to get to the food. On top of it, you can weld a couple of iron rods that will prevent animals from climbing inside. For the final disposal of gas, the inside of the trough can be additionally burned with a gas burner.

Since such a product is made of metal, it is extremely important, after the end of the work, to check it for sharp corners and protruding rods. If they are missed, the animals can be seriously injured while feeding.

Automatic feeder

It is also possible to make a bunker-type product at home, although its manufacture will require significantly more skills, strength and material. But in the future, due to the automatic feeding of the feed, it will help to significantly reduce the time required for feeding.

Hopper type product

Such a device consists of a trough and a storage tank, which is installed above it. For the manufacture of such a structure, an ordinary steel pipe of large diameter is suitable. The assembly is implemented as follows:

- The prepared metal pipe is cut into two sections. One of them is more, the second is less.

- The larger section, which should play the role of a bunker, is installed vertically. Further, a hole is cut in it from the side, and a pre-made iron stop is welded into the inner part.

- The remainder of the pipe is cut lengthwise into two equal parts. On one of them, special grooves are made for installing the sides (along the edges of the segment), as well as for secure fixation of the storage part.

- The sides are inserted into the grooves and welded.

- The upper part is put in place and also secured by welding.

- The product is checked for sharp corners and unnecessary holes. If available, they are corrected with a grinder and welding.

It should be noted that this type of feeder is suitable exclusively for dry food. In addition, it is most advisable to install such a container for food in subsidiary farms with a small number of pigs. When implementing such a project, instead of a conventional pipe, you can take other metal structures.

The correct feeder can significantly increase the effectiveness of the selected diet, as well as help maintain the health of the pets. But it is necessary to buy or make such a product yourself in strict accordance with the number of animals on the farm and the age characteristics of the herd.

DIY bunker feeders

Making an automatic feeder for adult pigs at home is extremely difficult. Animals eat a large amount of food, so the self-feeder requires a large body. For artiodactyls, it is easier to purchase the store version.

However, for piglets, breeders often use an automatic feeding method. The manufacturing process is simple:

- for the feeder you will need 2 buckets of 10 liters;

- the bottom is cut off in containers;

- buckets are fixed in slices to each other using construction glue;

- in the bottom bucket, holes are cut in the side walls in a circle.

Such a product should be secured near a vertical surface. The holes should be 30 cm wide. To prevent the young from scattering feed, a small sill should be left. Wet food and vegetables are poured into such feeders. Before making such a piglet feeder, the age of the animals should be taken into account. This way of serving food is suitable for individuals that are less than 5 months old.

A few words about sizes

It doesn't matter what choice the owner makes: buying feeders or making them. It is important to take into account that containers for young animals are not suitable for adult animals and vice versa. It is preferable to feed piglets from small containers with low sides, adult pigs will need other sizes. With a large number of livestock, to save maintenance time, long pelvis can be installed so that the animals can feed at the same time.

In the following table, you can find out in more detail the dimensions for different feeds, which will correspond to a particular age group in width. For suckers, width and height are indicated.

The second table shows the data on the length norms for animals belonging to different groups.

Stationary type of feeder

For small pigs, the feeder should be smaller, and for large pigs it should be larger. Do not use universal solutions - one design is not enough to raise young growth. For a large number of livestock, it is best to arrange not wide, but long troughs - of which the pigs can eat everything at the same time. For piglets, separate your territory with jumpers. You can find more detailed measurements of the feeders in the tables. Read about the recipe for mixed feed for pigs here.

Table 1. Width of feeders - wet and dry feed, different age groups of pigs.

| Age group of animals | Dimensions in cm for dry food | Dimensions in cm for wet feed |

| Adult pigs | 50 | 40 |

| Suckling pigs | 15 | 15 |

| Weaning pigs | 30 | 25 |

Table 2. Standards for the size of the length of the feeder per individual.

| Group | Feeder length per individual, cm |

| Sow | 40 |

| Boar | 40-45 |

| Suckling pigs | 15 |

| Young animals under 5 months of age | 25 |

| Youngsters over 5 months of age | 25-30 |