Why ventilation in a chicken coop is needed and why is it so important

Birds breathe during their life, giving off carbon dioxide. They eat heavily, resulting in a lot of droppings on the floor of the chicken coop. Dung is a source of ammonia and other fumes that are potentially harmful to birds.

Ventilation allows carbon dioxide to be removed from the chicken coop.

Carbon dioxide, ammonia and other gases will accumulate in the house air in poorly ventilated conditions. High concentrations of these substances will irritate the mucous membranes in birds.

They will often suffer from keratoconjunctivitis, the main symptoms of which are:

- puffiness of the eyes;

- lacrimation;

- discharge of pus from the eyes.

Stuffy indoor air affects the spread of all infectious diseases of chickens. Spores of bacteria and viruses accumulate in the air in large quantities, contributing to the spread of infection among the courtyard. Chickens of the cage content, which live in very cramped conditions, will suffer especially quickly.

Therefore, it is important to ensure that the air in the house is ventilated. It will avoid many infectious and non-infectious diseases.

Birds kept in close and stuffy conditions are more prone to pecking at each other and death.

Proper ventilation will avoid many poultry diseases.

Types and device

Most often, a conventional hood is installed in the chicken coop or supply and exhaust ventilation is made.... Both options are not laborious and the breeder can handle all the work himself. For example, in the first case, windows will be needed to ensure the flow of fresh air. With an open door and windows in the ceiling or above it with a latch, air circulation in the room is established.

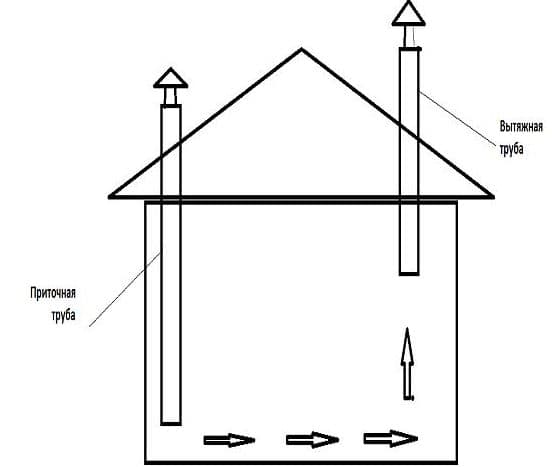

Sometimes poultry farmers give preference to supply and exhaust ventilation, which can be made with your own hands, considering it more efficient. How to make a hood correctly? For its construction, it is enough to buy two pipes with a diameter of 19-22 cm and a length of 1.9-2.1 m, if the area of the chicken coop is 12 sq. meters and place them in the right places.

Specificity of winter

In winter, especially chickens cannot be pampered with natural ventilation. They do not like cold and drafts. Therefore, when installing the ventilation system, it is necessary to take into account some of the nuances:

- When planning the house and its equipment, it must be borne in mind that supply ventilation will be very cooling the house. Therefore, it is better to place the pipes as far apart as possible. The best option is in opposite corners of the chicken room. The distance from the floor and ceiling of the end of the flow or exhaust pipe is acceptable from 20 to 40 cm;

- On the roof, umbrellas must be attached to the hoods so that rain or snow does not fall into the room;

- When there is no money to buy a deflector, then you can make it yourself or just bend the pipe at the knee;

- Pipes must be insulated with waterproofing material, because condensate can collect there;

- In winter, the valves on the pipes are closed;

- As an alternative to iron or plastic pipes, wooden boxes can be used;

- It is advisable to putty and paint them before installing them, then the thrust will be stronger, since the slots will close.

The vent can be either plastic or metal

Ventilation pipe deflector

To prevent leaves, birds, tree branches, rain and snow from getting into the pipes, umbrellas (fungi, deflectors) are installed on the pipes. In addition, the good performance of the ventilation system depends on the draft of the air in it. Thanks to the deflector, the air hits the fungus, forks, thereby reducing the pressure. And as a result, the thrust into the pipe increases. You can buy a ready-made umbrella, or you can do it yourself. The optimal and easy-to-use version is the Grigorovich deflector. Basic parameters without using formulas:

- The fungus in height should be equal to 1, 7 of the pipe section;

- The diameter of the umbrella is preferably almost twice the width of the ventilation pipe (more precisely, the width is determined by multiplying the pipe diameter by 1, 8);

- The diffuser width is calculated by multiplying the previous value by 1, 3.

Making a deflector yourself:

- Knowing the diameter of the pipe, draw the required circle with a compass on cardboard or paper, cut it out;

- Attach a paper blank to a metal sheet, circle the contours;

- Cut a circle with scissors for metal and other parts for fastening the finished structure;

- Connect all parts with rivets. If the sheet is stainless, then you can walk through the joints of the parts by welding.

Supply and exhaust option

It is quite simple to build a ventilation system in a poultry house with your own hands. At the same time, you do not need to invest large amounts. By installing an optimal ventilation system, not only the exhaust air is removed, but the temperature is also controlled. In a hen house, which has a healthy microclimate, chickens regularly lay many eggs.

If the ventilation system is ineffective, negative consequences can occur. The humidity indicator will increase, the air will stagnate, and harmful fumes from the litter will affect the condition of the layers. With increased dampness, fungi and pathogens develop faster.

If you correctly equip the chicken coop and ventilation in it, you can save the number of birds and even contribute to its growth. The equipment of the system for removing stagnant air will help create favorable conditions for the reproduction of layers. It is necessary to build such a system taking into account the area of the building. When equipping ventilation, it is important to exclude the possibility of drafts. Avoid them in the same way as stagnant air.

It is important to ensure not only correct air exchange in the chicken coop. You will need to think about how the lighting will be installed. Care should also be taken to ensure proper heating of the house. Often, oil radiators are chosen for this purpose. Usually it is hidden in a plywood box. If earlier chickens were simply allowed to walk outside, today a special pen is equipped next to the poultry house.

It is important to clean your chicken coop regularly. In this case, it is worth constantly monitoring the quality of feed and water. In a comfortable chicken coop, birds will feel as comfortable as possible. This will ensure good health and egg production.

This is the easiest and cheapest way; it is enough to make one or several small ventilation windows in the chicken coop. In this case, air enters and exits through open doors and windows. This method is best used in the summer when the doors and windows of the coop are open. In winter, the cold air coming from the door will be unpleasant and harmful to the bird. How to properly make natural ventilation in a hen house?

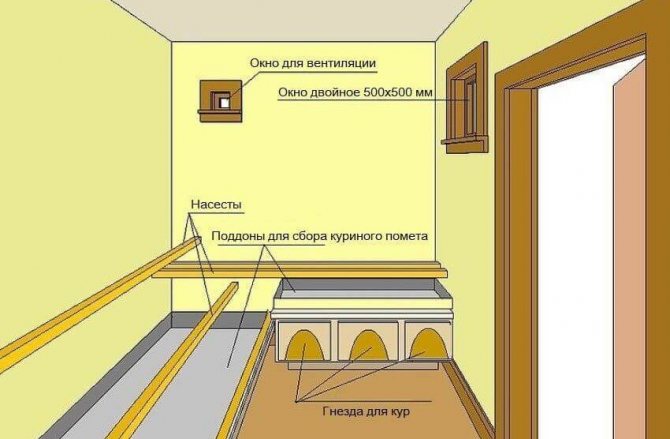

A window for ventilation is usually made above the door or in the ceiling. In the second case, sunlight will also enter through it. The window is made small. You can install a valve on it so that you can partially or completely close it in cold weather.

Cons of this method:

- it is ineffective in the heat, when the air temperature in the hen house and outside is the same; in general, the effectiveness of natural ventilation depends on the outside air temperature and the strength of the wind;

- in winter, on the contrary, it will cool the room too much, so additional heating will be needed;

- ventilation done in this way requires constant human supervision, you will need to open and close windows and doors on time.

This option is suitable as a temporary one for a small poultry house.

This option is more complicated and requires the installation of ventilation pipes. To do this, use pipes with a diameter of 20 cm and a length of about 2 m, usually plastic, you can take pipes intended for sewage. One of them is supply air, fresh air from the street enters through it, the other is exhaust air, exhaust air comes out through it. Alternatively, you can make wooden boxes, but they must be treated with an antiseptic and painted.

How to make ventilation in a chicken coop with your own hands

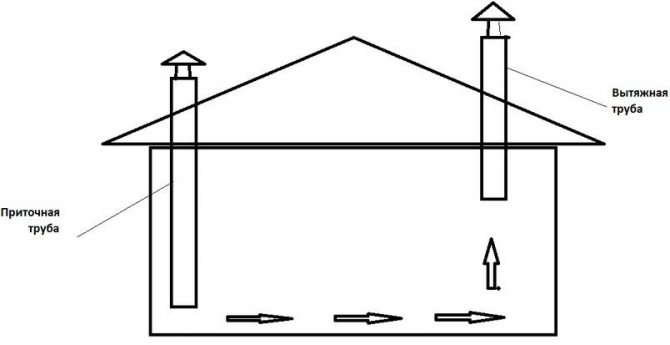

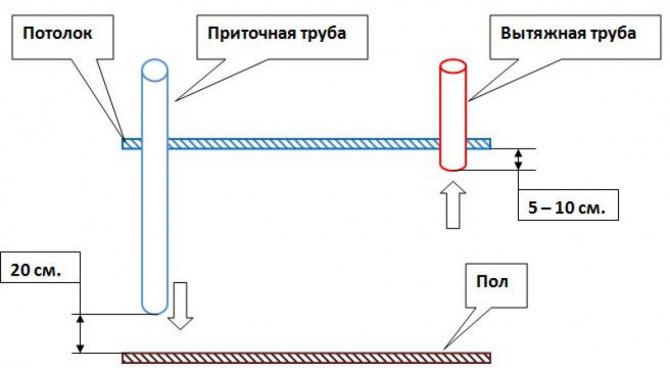

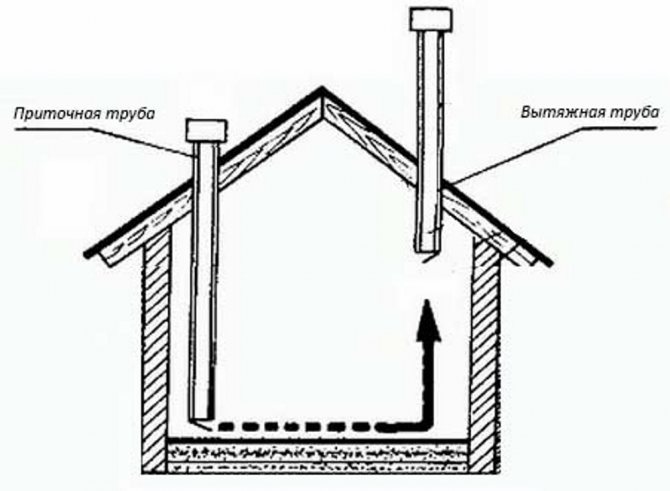

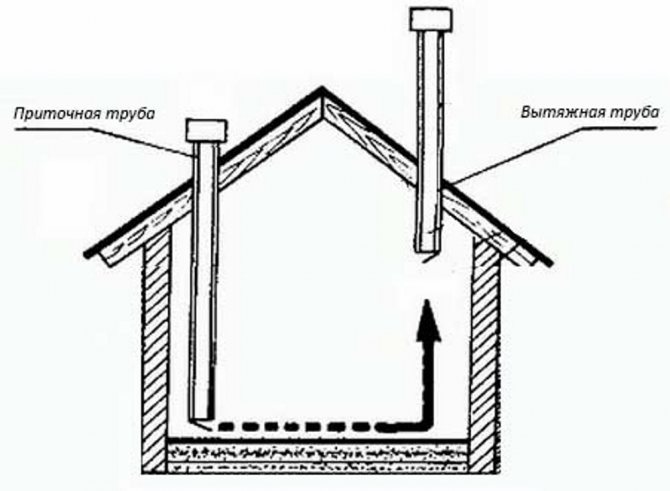

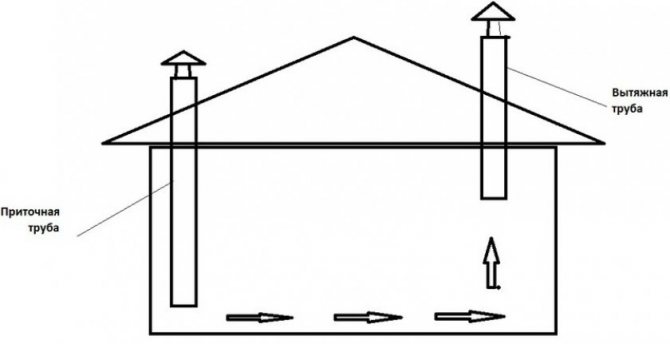

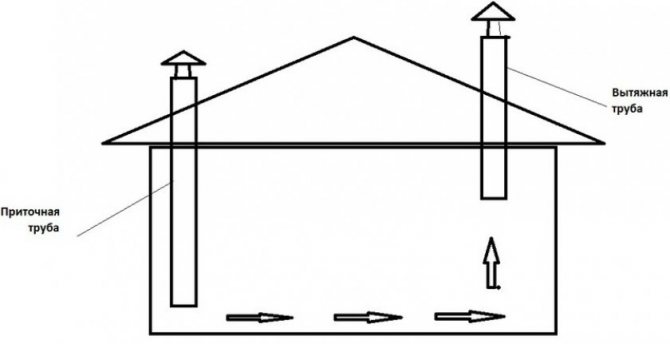

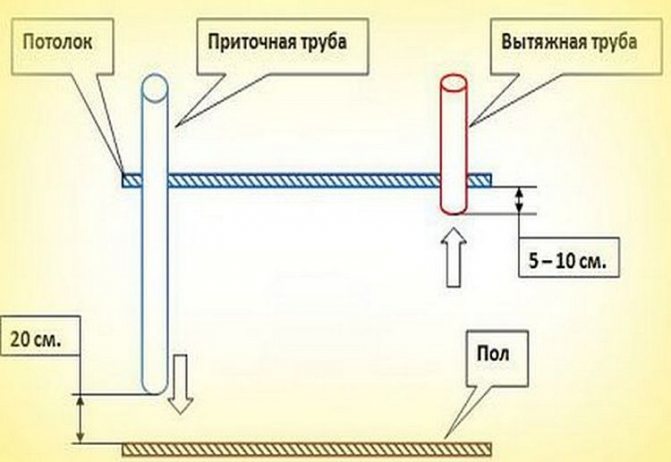

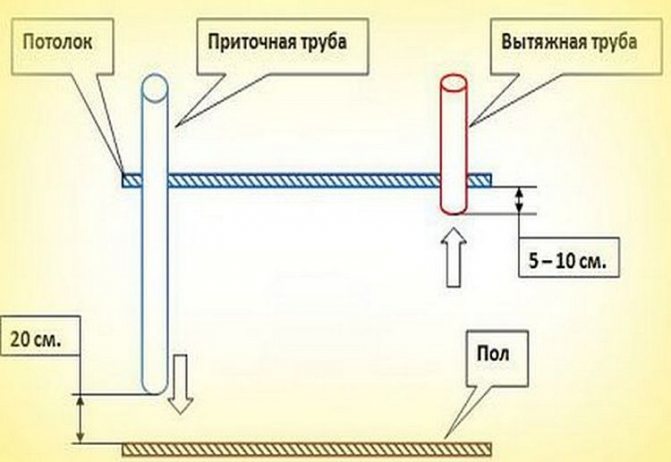

The exhaust ventilation pipe is best located above the perch, and the supply pipe is located away from it, in the opposite corner of the chicken coop. The lower part of the supply pipe should be about 20 cm from the floor, and the upper part should rise 30-40 cm above the roof. The exhaust pipe should start 20 cm from the ceiling of the barn, and rise 1.5 meters above the roof. Umbrellas are put on the tops of the pipes to protect them from rain and snow. The location of the pipes is shown in the figure.

- Secure the pipe with a clamp from the outside of the roof. Then the pipe entry point is sealed with polyurethane foam.

- To prevent condensation from accumulating in the pipe, it is insulated.

- A damper can be installed on the supply pipe to regulate the flow of incoming air.

- For pipes in the roof, holes are made using a jigsaw.

We suggest that you familiarize yourself with: How to give activated charcoal to a cat when vomiting

Supply and exhaust ventilation in the chicken coop is more efficient than natural ventilation without the use of pipes. This is the best way to ventilate a small poultry house of about 12 square meters in a private household.

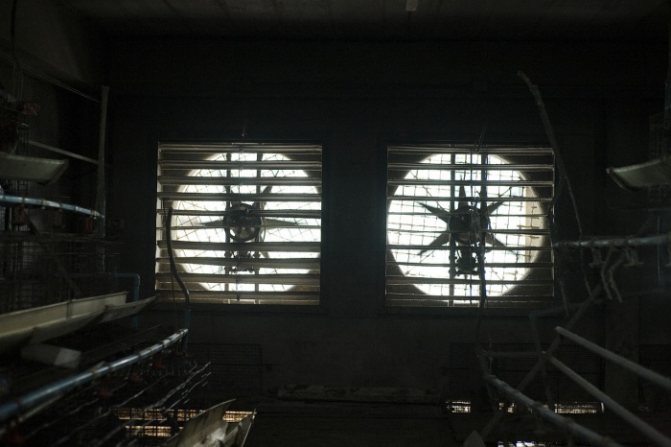

This type of ventilation is rarely used in private households, but it can also be arranged. The disadvantage of artificial (mechanical) ventilation is additional power consumption. The fan is inserted into the window, if you are familiar with electrical engineering, then you can install sensors that turn it on and off at certain temperatures and humidity. You can also install ventilation pipes in the attic of the chicken coop, and mount the fans in the ceiling.

To install mechanical ventilation you will need:

- fan,

- the wire,

- plywood,

- switch,

- insulating tape.

The fan is usually installed in a window, for this, the glass is removed, and plywood is inserted in its place with a hole of the required size for the device. Then a fan is inserted into the hole, a cable with a switch is connected, the connections are insulated.

You can also install a fan in the supply or exhaust pipe.

Attention! The chicken coop is a room with high humidity, so the wiring must be well insulated, and it is better to bring all the electrical elements outside.

Most often, artificial ventilation is installed in poultry farms and large poultry houses. It is beneficial if you have a large poultry population - more than 100. In other cases, the energy costs will be too high.

Ventilation for the chicken coop is easy enough to do with your own hands. The easiest way is to make one or more windows for air intake, but this is not the most efficient option. For a small poultry house, it is best to use two pipes for supply and exhaust ventilation. Good ventilation in the hen house is one of the important factors in the health and performance of hens.

How to make ventilation in a chicken coop with your own hands using mechanical traction? Forced ventilation in a home chicken coop can be equipped if the room has a large area with a large number of birds. These coops are usually built in poultry or farmland areas where electricity is available and fans can be installed.

And sometimes in small chicken coops, a natural ventilation device is not enough due to poor draft or installation errors. Therefore, if you did something wrong, it is better to install additional ventilation systems.

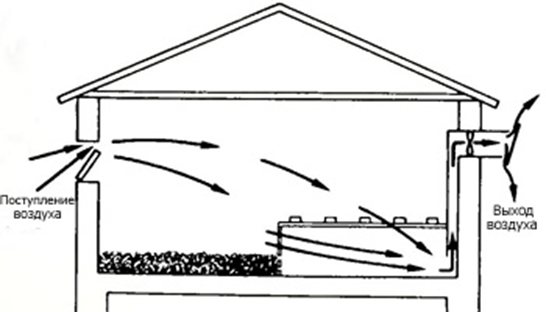

The mechanical ventilation system uses a plastic pipe that is equipped with fans. Sensors are installed in the axial part of the pipe. Their principle of operation is to control the level of humidity and temperature in the poultry house.

The installation of a forced system for a chicken coop is done according to the scheme:

- To ventilate the house, a location must be chosen where the fans will be installed. A simple option is window installation, for this you must first remove the glass and make sure that the dimensions of the openings are suitable for the fans.

- Cut a piece out of the plywood sheet and install it with self-tapping screws into the hole where the fan will be mounted.

- Install the fan.

- The connection to the network is carried out using a cable.

- Install a switch in the ventilation system.

- Wrap the places where the wires are clamped with electrical tape.

It is important to wrap the places where the wires are clamped with electrical tape.

Supply and exhaust

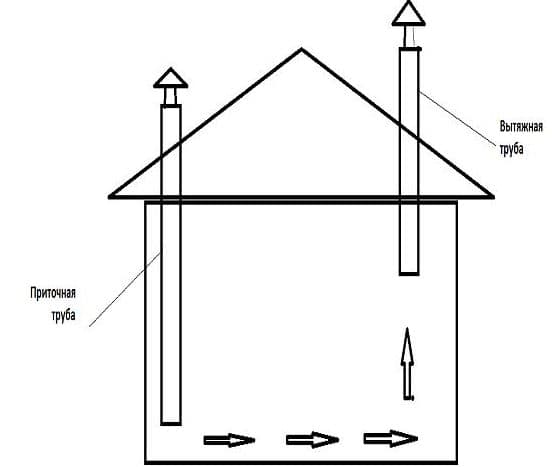

Due to the difference in temperature and pressure inside and outside the house, air movement is created - this is how natural ventilation works. Installation requires two pipes. The air duct for the inflow of wind masses is located at a distance of 20 cm from the floor and runs vertically through the entire house, the pipe is led out to the roof.

Uncomplicated fan system

Depending on the area, the diameter and size of the pipes are selected. Recommended standards for poultry houses up to 12 m2:

- duct length 210 cm;

- section diameter 22 cm.

For chicken coops with a larger area, an individual project is made. It is impossible to select air ducts without preliminary miscalculations. Indeed, if the cross-sectional diameter of the duct is excessively large, then the air flows in the room will create a draft. The fertility of birds will worsen.

Hood

Elementary hood - air outlet in the wall

Ventilation can be carried out without any investment, it is enough just to make an extractor hood in the chicken coop. It can be represented as a window in the wall. Air will enter from the street through the front door, and will be discharged through a hole in the wall. The window must be made so that there is no draft during natural ventilation.

Forced ventilation in the hen house is suitable for large areas, ensures circulation regardless of weather conditions. Mechanical devices drive air in the required volume, without the formation of stagnation of exhaust air. The main disadvantage of mechanical ventilation is that it is powered by electricity.

Exhaust window for natural ventilation

Supply and exhaust

Mechanical is more suitable for poultry farms

The main mistakes when arranging the ventilation system

To avoid the main mistakes, here is a list of them:

- Location of windows or inflow and exhaust points (pipe openings) on adjacent walls of the room. In this case, there will be normal air exchange in one corner (between the walls where the windows / air ducts are located), and in the opposite corner, the air will stagnate. The correct scheme is when the supply and exhaust points must be located on opposite sides.

- Using noisy fans.Chickens can live comfortably with the usual noise background, but they will be afraid of an unusual too loud sound. Therefore, fans, if they were not previously in the chicken coop, should be chosen quiet, or in noise-insulated cases, or installed away from the perch. Unusual loud noise can scare the bird, impairing egg production.

- Installation of heavy pipes on a "weak" structure. In households, poultry houses are usually either built cheaply or used "light" sheds. If in such a room it is necessary to lay an air duct under the ceiling (especially if it is a metal rather than a plastic air duct), it is necessary to estimate whether the structure will withstand the additional weight.

- Savings on insulation. In the winter season, a layer of thermal insulation will prevent the pipe from freezing due to condensation, and will help to partially save on heating.

- Lack of dampers to close the air ducts. In severe frost, sometimes it is necessary to completely shut off the air supply, or reduce it to a minimum - so as not to freeze the bird.

Self-assembly of the mechanical system

Sequencing:

- Cut a square hole in the log wall of the shed for the ventilation pipe almost under the ceiling, but not end-to-end. On the inside, from the top edge of the cut hole to the ceiling, there should be about 10 centimeters left without affecting the upper strapping log.

- Insert the pipe into the finished hole and fix it in the slots with square plywood.

To check the performance of the self-assembled structure of the chicken coop exhaust system, you need to enter the room on a windless day, tightly closing all the doors and the window.

Then take a piece of newsprint and attach it to the opening of the ventilation exhaust pipe. If the sheet does not fall to the floor and is firmly pressed against the inlet of the pipe, then this indicates that the ventilation is working.

Requirements

Support modes

To create a suitable microclimate for chickens in the poultry house, it is necessary to maintain certain parameters of temperature, humidity and air purity.

The temperature regime for keeping an adult bird is from 16 to 18 degrees. For chickens - from 18 to 26 degrees. Depending on the age of the livestock.

Relative humidity - 60-80%. An increase in the indicator will lead to the development of pathogens. Decrease - to the dustiness of the chicken coop. And respiratory tract disease in chickens.

The volume of fresh air entering the room where chickens are kept: in winter - 0.7 m³ / hour. In summer - 5.5 m³ / hour.

The speed of the air flow should not exceed 0.2-0.4 m / s - in the cold season. And 0.4-0.8 m / s - in a warm one.

Other nuances

It is important to consider one more fact. The chicken coop must be cleaned regularly, freeing from manure.

It is a source of ammonia. And a favorable environment for the development of harmful bacteria.

Stocking density: no more than 5 egg chickens are kept per 1 m² of floor. And about 2-3 broilers.

If the concentration of carbon dioxide in the air of the hen house is 5% or more, the chickens begin to suffocate. This is a common cause of bird mortality.

Chicken coop ventilation device options

When arranging ventilation for a home chicken coop, it is quite possible to do it yourself.

It is important to do everything correctly to ensure a comfortable environment:

- The temperature in the cold season is not lower than 16⁰ for adults and 28⁰ for chickens.

- Humidity 60 to 80%.

- Air flow speed - 0.8 m / s maximum in summer and no more than 0.5 m / s in winter. If these indicators are exceeded, drafts will walk inside the room.

The ventilation scheme in the chicken coop and in other buildings is based on the same principle. They proceed from the area of the premises and the number of birds. When determining the performance of the system, the following moment is taken as a basis: for every square meter there should be 5 chickens.

To resolve the issue with ventilation, you need to decide on its type.The next step is drawing up a detailed scheme, then purchasing materials. Then it remains only to follow the technology and perform the necessary work.

Organization of natural air exchange

It is based on the parameters of the air environment: temperature, pressure, wind speed. This type of ventilation can be either unregulated or organized. Unorganized ventilation occurs through leaky doors and windows, air infiltration is carried out through walls and ceilings.

For organized air circulation (aeration), you need to provide a small window, placing it in the ceiling above the perch or directly above the doorway. To control traction, the window is made in the form of a window.

The door in the open position will supply the house with fresh air, and the used air will leave through the window. This method is good for the warm season. In winter, the effect of such ventilation is negligible. It is unprofitable because a lot of heat goes away. You will have to spend a lot of money to maintain the optimal temperature inside the house.

Why is normal ventilation necessary in a chicken coop?

The main task of the ventilation system in any room (including in a chicken shed) is to remove stale musty air and provide an influx of fresh air. That is, the system must provide air exchange in the required volume, and constant.

This is required for several reasons:

Ventilation creates and maintains the required temperature regime in the poultry house, which is optimal for the life of the birds. On hot days, the system eliminates stuffiness, and on cold days, it does not allow the humidity to rise. Chicken droppings are not at all harmless: when they accumulate, they begin to release dangerous ammonia. The problem is not even a terrible smell, but the fact that it negatively affects the health of birds and can lead to severe poisoning.

It is especially important to remove ammonia fumes during the winter months when the door in the shed is tightly closed and the concentration of the hazardous substance may increase. Ventilation (even the simplest system) allows you to easily control the microclimate in the barn, including the level of humidity. You need to fight with both too dry and too humid air - they are equally harmful to birds.

Optimal microclimate: temperature, humidity, air exchange

It is necessary to equip the ventilation system in the hen house, focusing on several prerequisites (norms). The organization rules are quite simple, so the system itself can be made by hand.

Large industrial chicken coop

Fundamental rules:

- broilers are sensitive to drafts, therefore, it is imperative to adjust the air outflow to avoid their occurrence: the air flow rate should not be too high, and it should not fall directly on the birds;

- to prevent freezing in winter, it is necessary to monitor the temperature, be sure to reduce the inflow during frost to the permissible minimum (or ensure the air is heated to a comfortable level);

- in severe frosts, the supply ducts can be completely closed, periodically opening them for ventilation.

The volume of air exchange directly depends on how many birds are kept in the barn. The average calculation is as follows: 4-5 birds must be placed per 1 m2, no more.

What you need to know before installing

More chickens, more air

To make a ventilation system in a chicken coop, you need to follow some rules under which ventilation will function correctly:

- The volume of air entering the room directly depends on the number of heads. The more chickens, the more supply air is needed. On average, there are 4–5 poultry per 1 m2.

- The ventilation system must be regulated so that the birds do not freeze during the winter. They feel drafts well, so the inflow at this time should be kept to a minimum.

- To prevent heat loss, a fine mesh grill must be installed on the supply pipe. If the frost is very strong, the flow must be shut off.

- To keep the chicken coop constantly saturated with fresh air, you should regularly clean up the droppings. The room must always be clean. After all, whatever the ventilation system, if the room is dirty, ventilation will not help much.

By following these rules, you will provide the chickens with maximum comfort, and productivity will increase significantly. But the question arises, how to make a ventilation system? First you need to decide on the type of ventilation. Here are three of them:

- natural ventilation;

- supply and exhaust ventilation;

- mechanical ventilation.

Let's take a closer look at each of them.

Do it yourself

Even during the design of the chicken coop, each farmer thinks about ventilation - what it will be. There is no need to invest a lot in expensive mechanical ventilation if only a few chickens are kept in the house. Below we will consider how to make ventilation so that it is as profitable, inexpensive and efficient as possible.

Ventilation must be efficient but inexpensive.

Natural ventilation

If the poultry house is planned only for a warm season, then natural openings in the room are quite enough:

- window;

- a door.

This ventilation is sufficient, given the constant movement of cool outside air and air heated inside the room. The door should not be too large, its dimensions should only allow for easy cleaning inside.

Windows are made on other walls under the ceiling - air warm from breathing and droppings will rise up and go into such ventilation windows. Cool outside air will flow freely through the door, which can be left open all day in summer.

Pros of natural ventilation:

- cheapness - such ventilation costs practically nothing;

- simplicity of arrangement - in each chicken coop a door and at least one window is supposed.

Cons of natural ventilation:

- small volume of ventilated air;

- strong dependence on weather conditions;

- the constant presence of a person is required to control ventilation;

- inability to use in winter.

Natural ventilation means that clean air will flow through windows and doors.

Supply and exhaust ventilation

Let us analyze the scheme and principle of operation of the supply and exhaust ventilation. This ventilation method is perfect for a small year-round farm. Chickens in a poultry house with such ventilation overwinter well without much expense.

Supply ventilation is made from plastic pipes with a diameter of 10-20 cm. You will definitely need two pipes - through one of them, dirty air will leave the poultry house. Through the second pipe, clean air enters the inside of the chicken coop.

Consider a phased installation of supply and exhaust ventilation:

- The chimney opening must be under the ceiling - a maximum of 20 cm away from it.

- The opening of the supply pipe is located at the floor, 25-30 cm from it.

- Both ventilation pipes should be in opposite corners of the coop for best ventilation.

- The chimney is usually located in the most polluted part of the house - above the perches.

- The outer part of the chimney is taken out 1-1.5 meters above the roof of the chicken coop.

- The outer part of the supply pipe is always 70-80 cm lower than the exhaust pipe.

- Both outdoor openings are protected from atmospheric precipitation with tin umbrellas or an L-shaped pipe bend.

The photo shows a diagram of the supply and exhaust ventilation in the chicken coop.

Advantages of supply and exhaust ventilation:

- relative cheapness;

- the ability to use throughout the year;

- there is no need for the constant presence of service personnel.

Cons of supply and exhaust ventilation:

less volume of ventilated space than with mechanical ventilation.

Mechanical ventilation

If there is a large poultry house for 50 or more chickens, then passive supply and exhaust ventilation may not be enough. In this case, it is preferable to have electric forced ventilation.

It consists of fans installed at the openings of the supply and exhaust shafts. Connected to the mains, they can turn on automatically on time or at the request of the farmer. The high energy consumption in this case is compensated by the profit from healthy layers and broilers.

In chicken coops, where a very large livestock is kept, it is better to do mechanical ventilation.

Mechanical ventilation advantages:

- allows you to ventilate a large space;

- provides fresh air on large personal subsidiary plots;

- can be used all year round.

Disadvantages of mechanical ventilation:

- high cost of installation;

- the need to supply electricity;

- regular waste of electricity.

In the video, the farmer talks about how he made ventilation in his chicken coop.

Hood in the hen house: how to make ventilation with your own hands

To get rid of the high humidity in the air and the pungent ammonia odor that accumulates in the hen house in winter, it is necessary to equip the house with an exhaust system.

To do this, it is enough to clearly follow the instructions and scheme for creating ventilation, made by hand and tested in practice by other poultry breeders for several winter periods.

People who have decided to have chickens in their backyard should know that ventilation in a chicken coop is not a luxury, but a necessity for creating a favorable habitat for feathered pets.

Even because of the small temperature difference inside the house (5 degrees) and outside (-6 degrees), condensation begins to form on the walls and ceiling, causing increased humidity, unfavorable for birds.

Air currents should be circulated in any room where birds are kept

We offer you to familiarize yourself with Ventilation in a private house - buy at a bargain price with installation

This is especially true if the litter is also wet (wet sawdust mixed with chicken droppings). Without ventilation, when humidity is high, mold begins to form, which is detrimental to the health of poultry.

All the accumulating ammonia and the pungent odor emanating from the droppings mixed with waste sawdust rises up to the ceiling of the chicken coop along with the heated humid air.

If ventilation is not carried out in the barn and there is no flow of fresh air rich in oxygen from the street, then in winter not only the bird, but also the owner is not comfortable here: the dense stench from bird feces and their waste products cuts through the eyes.

In addition, wet condensation will settle on the ceiling and walls of the chicken coop, leading to the formation of mold.

Therefore, there are certain requirements for the organization of ventilation for the poultry house:

- there must be free continuous access of fresh air;

- use equipment of good reliable quality so as not to make frequent replacements in case of breakdown.

Natural ventilation scheme

House ventilation can be done in several ways:

- Forced ventilation system, when the air flow is created due to the mechanical action of the fans. A similar air duct system can be: supply, if the fan is placed on the supply pipe;

- exhaust, when the fan is installed on the exhaust pipe;

- combined - simultaneously combine the supply and exhaust ventilation systems in the same room;

- supply and exhaust with a recuperator having an anemostat installed at the outlet as an air supply control.

Natural ventilation works by natural forces that obey physical laws. Warm air, which has a lower density and mass, is lighter than cold, heavier air coming from the street.

Pressurized by the cold air flow at the bottom of the floor, the warm air rises upward. It is pulled out through the chimney shaft into the street.

Most often, supply natural ventilation is installed in the exit door of the chicken coop in its lower part.

In winter frosty time, so that the cold does not pull on the floor, such a round inflow can be slightly covered by twisting to the right. The exhaust pipe must be located above the supply ventilation.

A simple ventilation scheme in a hen house in a natural way

In addition, in order to obtain natural heating, when the temperature in the barn room rises additionally due to the chickens' own heat, caring owners put on the floor a deep bedding about 40 cm high from dry sawdust, leaves, hay and straw for the winter.

It is advisable to spray such a bedding once with the preparations "Shining-2" or "EM". They are based on microorganisms that easily process and decompose organic matter that is excreted in abundance by the bird.

They are also used for mulching the beds.

It is advisable to install a ventilation pipe in the corner of the room in order to lead it directly through the attic to the roof above the ridge at a distance of 1.2 meters.

If you make a hole in the wall for a mechanical hood, then the plastic pipes will have to be additionally connected with a corrugated tin elbow, securing with clamps.

In the upper part facing the street, in the hood made of plastic pipes, a convex round mushroom shutter should be installed, which will protect against precipitation in the form of raindrops and snow drifts.

In frost, the condensate tightens the entire pipe lumen with a solid monolith, which cannot be easily knocked out in the frost. Therefore, some craftsmen recommend directing the outer part of the pipe not up, but down.

This will eliminate ice build-up around the edges and inside the pipe walls.

The ventilation pipe can be insulated with cotton wool and wrapped in foil. Or use another option for thermal insulation of exhaust pipes - the hood is covered with a special foil insulation for pipes, and a heating cable can be placed inside.

For the manufacture of exhaust ventilation in the chicken coop, you will need spare parts:

- centrifugal fan - 1 pc .;

- sewer tees in an amount - 2 pcs.;

- conventional gravity sewer pipes with a diameter of 110 mm;

- valve - 1 pc .;

- transitions (section 110 to 124) - 2 pcs.;

- time relay for adjusting the on / off mode - 1 pc.

Sequencing:

- Cut a square hole in the log wall of the shed for the ventilation pipe almost under the ceiling, but not end-to-end. On the inside, from the top edge of the cut hole to the ceiling, there should be about 10 centimeters, without affecting the upper strapping log.

- Insert the pipe into the finished hole and fix it in the slots with square plywood.

To check the operability of the self-assembled structure of the chicken coop exhaust system, you need to enter the room on a calm day, tightly closing all the doors and the window.

Then take a piece of newsprint and attach it to the opening of the ventilation exhaust pipe. If the sheet does not fall to the floor and is firmly pressed against the inlet of the pipe, then this indicates that the ventilation is working.

The ventilation device is carried out in steps. First, the components needed for the hood are purchased.

Ventilation from plastic pipes

Conventional non-pressure plumbing pipes with a diameter of 110 mm are sold in pieces of 2 and 3 meters at a price of 300 rubles to 400 rubles in hardware stores, in construction markets, in plumbing stores.

The height of the chicken coop is pre-measured in order to calculate how many meters of pipes will be needed for the manufacture of ventilation. In rooms with a large area, you can additionally use a fan.

When making a hood you will need:

- plastic gravity sewer pipe with a diameter of 110 mm, a length of about 4 meters;

- plastic tee;

- bends (with a diameter of 110 mm) - 2 pcs.;

- clamps for attaching the pipe to the barn wall;

- fitting;

- narrow rubber hose 1.2 meters.

To remove condensate that accumulates in the exhaust pipe, a plug is attached at the bottom of the plastic tee to a small round hole. A special metal fitting is screwed into the plug.

A narrow hose is already put on it, which is lowered into the canister to drain and collect the moisture formed in the pipe.

The accumulated drops of condensate flow down the pipe, accumulate first in the tee, then they enter the prepared container through the hose.

Natural ventilation system in the chicken coop

Constant air exchange in a sealed room with a bird, especially in winter, is vital for the animals in the home.

In the process of breathing, the percentage of oxygen in the air inside the hen house decreases and is replaced by carbon dioxide.

Therefore, an artificial draft is required, otherwise the atmosphere in a closed room will become suffocating, damp and difficult for feathered pets to live.

We suggest that you familiarize yourself with Do you need ventilation in the foundation of the house

Without air ventilation, the bird will be sick and may even die. Such conditions are suitable only for the development of microflora harmful to animals in the form of fungus, mold and other nasty things.

The main features of the installation of ventilation pipes:

- The chimney for a poultry house with a gable roof, in its upper part, should not go beyond the horizon of the roof canopy.

- For a chicken coop with a flat roof with a slope, lower the pull-pipe from the roof to a distance of 30-40 centimeters.

- The distance of the ventilation duct from the floor, taking into account the litter, should be at least 25-35 centimeters.

- The supply and exhaust pipes should be located on opposite sides of the utility room.

- From the street side, a small through hole with a diameter of 5 mm must be drilled in the bend of the chimney from below to discharge the accumulated condensate outside.

- Periodically, 2 times a year in spring and autumn, it is necessary to disassemble the exhaust structure from the pipes and clean it well from accumulated dirt, cobwebs, dust, dry leaves and other debris.

Conclusion

Strictly observe the rules of competent installation and the mode of operation of the ventilation built into the chicken coop, and then the egg production and the number of birds will surely increase, which means that the chickens will bring additional profit to their owners /

Novice poultry farmers do not even know about all the difficulties that they will have to overcome on their way before adjusting the conditions for keeping chickens. The first step is to establish the operation of the ventilation system in the chicken coop.

Breeding chickens is a troublesome business, so you need to try to ensure that it has the maximum return. The satisfactory productivity of poultry, along with other measures, is provided by the hood in the chicken coop.

Without the supply of clean air in a confined space, the health of the chickens is threatened, therefore, egg production decreases.

In a hen house, as in any house, there are ammonia vapors dispersed throughout the house.

If fresh air does not come from outside and harmful fumes reach a high concentration, its inhabitants begin to get sick, and in some cases this becomes the cause of death.

Feathered and high temperatures are poorly tolerated, therefore a system that allows air to circulate is simply vital for them.

note

Without ventilation, it is difficult to control the humidity of the air. Birds are equally ill in an excessively humid and dry room.

Why ventilation is needed in a chicken coop

It is clear that ventilation is needed to provide chickens with a normal life, then they can produce a large number of eggs all year round, grow and gain weight

In winter, the bird is especially susceptible to disease, therefore, when thinking over the ventilation system, it is important to take this factor into account. Air exchange occurs due to the hood, in which a powerful fan is installed

Musty and bad air comes out into the street, and fresh air gets inside.

You need to ventilate the chicken coop for several reasons:

- the content of such a substance as ammonia in the air accumulates over time due to the chicken droppings in which it is contained, and the unpleasant smell that spreads around the room is only the beginning of the trouble. Ammonia vapors, like all other living organisms, are harmful to chickens. They can cause intoxication, destruction of immunity, and also cause poisoning. A large amount of such gases collects in closed rooms during cold weather, just when, to maintain the temperature, the owner of the poultry house tightly closes all the cracks so that cold air does not get inside. To avoid this, be sure to ventilate, and so that the bird does not freeze, equip with heaters.

- thanks to the use of ventilation, it is possible to achieve the effect of maintaining the temperature in the hen house. Summer is often dry and hot. Fresh air and pleasant coolness will please the birds and they will feel better. Comfortable conditions for birds have a beneficial effect on its behavior. If the room is too hot, then the pet suffers from this and the ability to lay eggs is reduced several times.

- Another problem that ventilation in indoor chicken coops can cope with is the change in air humidity. Too dry air in a chicken coop negatively affects chickens. In the same way, damp air where they are located negatively affects. It is possible to regulate the concentration of moisture in the air through the use of ventilation, injecting cool air from the street in summer, providing the bird with comfortable conditions, and in winter removing moisture from the room by pumping air with a high content of evaporation products from manure and drinkers into the street.

Thus, we solve several problems at once with a competent approach and installation of ventilation equipment. Normal and positive dynamics of the life of chickens and an increase in efficiency and the ability to lay eggs is impossible without the use of equipment to maintain the temperature regime, exchange air and reduce the concentration of moisture in the room.

Having decided to start growing chicken and getting a sufficient number of eggs not only for yourself, but also for sale in order to compensate for the costs of their maintenance and get a small profit, you should not expect good results without installing the hood. The efficiency of work will depend on certain factors that you can easily calculate yourself.

The role of ventilation in creating a poultry house microclimate

In a hen house, as in any house, there are ammonia vapors dispersed throughout the house. If fresh air does not come from outside and harmful fumes reach a high concentration, its inhabitants begin to get sick, and in some cases this becomes the cause of death.

Feathered and high temperatures are poorly tolerated, therefore a system that allows air to circulate is simply vital for them.

Without ventilation, it is difficult to control the humidity of the air. Birds are equally ill in an excessively humid and dry room.

This problem becomes especially urgent in winter, when all livestock are constantly in a confined space. The air accumulates carbon dioxide, water vapor, plus toxic ammonia released by the droppings. Decaying litter and scattered feed are a good basis for the reproduction of harmful microorganisms.

Just opening the door is not an option. This way of providing fresh air can create another problem - freezing of the ridges. Dangerous for laying hens and sudden temperature changes, drafts. Therefore, the presence of a competent general ventilation scheme in the hen house in winter is a matter of extreme necessity.

Natural ventilation

Do-it-yourself ventilation in a chicken coop is simple and affordable. For a small poultry house, you can equip a simple device that will provide natural draft. It is provided with a window, which is located above the door of the chicken coop or directly in the roof of the room. The use of this ventilation is prohibited in frosty winters, the reasons are the likelihood of frostbite of the bird.

Supply and exhaust system

For the winter period, it is necessary to choose a suitable ventilation system, install it according to the rules. The best option is a device that provides both supply and exhaust ventilation. This will give the opportunity for poultry to develop and lay well throughout the year.

In a poultry house with an area of 20 sq. m (per hundred birds), the device is equipped as follows:

- you need to take two pieces of a two-meter plastic pipe with a diameter of 20 cm, they will provide the inflow and outflow of air;

- each pipe must be installed in opposite corners so that the air flow covers almost the entire area of the room;

- the exhaust pipe is installed near the bird roost: the lower part is twenty centimeters from the ceiling, and the upper one is at a height of one and a half meters above the roof level;

- the supply pipe is located in the corner farthest from the roost of chickens (in winter, frosty air will not blow over the birds): the lower part of the pipe is from twenty centimeters from the floor, and the upper part is at a height of thirty centimeters above the roof level;

- on the upper holes of the plastic pipes, both exhaust and supply, you can put on special umbrella hats, which will serve as protection from precipitation.

A pipe made of plastic or metal is insulated, because in winter its walls will collect condensate. Gradually, this condensate in the form of freezing ice will narrow the lumen of the pipe, and over time will completely block it. As a result, the house poultry house will be left without a ventilation system.

To regulate the intensity of ventilation devices in the hen house, special dampers are installed on the pipes. Supply and exhaust pipes can achieve good natural ventilation and create optimal conditions for keeping chickens of different breeds, including broilers and quails.

To keep chickens of different breeds, including broilers, supply and exhaust pipes can be used to arrange ventilation

Wind force device

Wind is a natural flow of air that can be used in the process of equipping a ventilation system. The original ventilation device operates from wind power, according to the exhaust principle of natural draft, natural air exchange takes place. Such a hood is convenient in a room of no more than eight square meters.

How to make such a device correctly? You can build it as follows:

- build a vertical channel from wooden boards in the form of a square measuring 20x20 centimeters;

- divide the box into two sections;

- close the upper exit, and coat the outer walls with a special hermetic substance and paint;

- drill small holes in the side walls of the box.

In one sector, the air moves into the chicken coop, and in the second it goes outside.

Types of ventilation

There are two types of ventilation devices in the poultry house:

- natural;

- mechanical.

The first variety will be relevant in rooms with a small number of individuals. To equip the chicken coop in this way, you do not need to use additional means, such as a fan, filters, and so on. The whole process lies in the simple laws of physics. A natural ventilation device is an economical solution for cleaning a building from stagnant air and dampness, replacing it with fresh volumes.

The second option is most often used on large farms where several hundred birds are raised. The system is easy to set up on your own, but it can take quite a long time. And one cannot do without financial investments in such a matter. Forced ventilation implies the use of special devices that are powered by an electrician.

Regardless of the chosen scheme, it is important to adhere to some of the features and rules for independent arrangement of the poultry house:

- The volume of air supplied is calculated in relation to the number of birds. One square meter is the residence of 4-5 individuals.

- The system should be equipped with adjustment elements. The poultry farmer must first install valves, vents or windows that will change the flow of fresh air. It is minimal in winter and completely open in summer.

- Even conventional supply and exhaust ventilation can be mechanical if equipped with a fan.

The natural option has many benefits, which are especially noticeable for bird house owners and large farms. Today, ventilation of a chicken coop from plastic pipes is widespread. This is due to the simplicity and availability of the design, as well as many advantages. Among them:

- high quality and efficiency of work in the absence of connection to the electrical network;

- the ability to work around the clock;

- high efficiency in a small building;

- silent operating mode.

Any supply and exhaust systems of a natural type also have disadvantages. The main one is the low efficiency when working in large buildings. Such an outlet simply does not cope with the processing of large air masses, so you have to equip it with additional devices. If you intend to do a large commercial business, then the best option is mechanical ventilation, powered by an electrical network.

Fundamental rules

The key features of a natural ventilation system are familiar to every experienced poultry farmer. However, novice farmers hardly know what the construction principle is. To clarify the key points, you should carefully study the existing instructions, as well as review many videos. Homemade ventilation is created in three variations and differ only in the placement of key nodes.

The simplest option involves installing the hood directly under the ceiling or in the roof itself. For a successful arrangement, it is required to acquire only an adjustable door, which will control the supply of traction through a through hole, protecting the chicken coop from precipitation. Such a scheme is used extremely rarely, due to the lack of comfort of use due to the inconvenient location.

The following scheme is more popular among industrial farmers. It is relevant in buildings with an area of up to 20 square meters, where about 100 chickens live. It is not difficult to make such ventilation yourself:

- First you need to find two-meter pipes with a diameter of 20 centimeters.

- Next, the poultry house should be equipped with places for future pipe holes.One pipe is fixed to the ceiling, and the other to the floor. If you properly prepare the ventilation system, this will allow you to cover the largest possible area.

- Then it is required to equip the chimney. The expected effects can be achieved when the chimney is 1.5 meters above the roof level.

- The second pipe is the supply pipe. It is placed at a height of 0.3 meters from the floor.

When arranging a ventilation system, it is important to completely protect the building from water leakage in the form of precipitation through the holes. For this reason, the street ends of the pipes are covered with special umbrellas. Such elements are easily made by hand in a few minutes. Such a device will be effective if doors on ventilation windows are installed in the chicken coop. Ventilation in the hen house is equipped with an insulating material that will save pipe sections from condensation.

More complex scheme

What is the purpose of the ventilation system, every farmer knows, both a beginner and a more professional one. However, not everyone has heard of such a unique technique as the use of wind power to obtain the expected result. True, such ventilation will become indispensable only for small buildings with dimensions of up to 10 square meters. During construction, except for boards, only paint is used. The system is constructed as follows:

- To begin with, a vertical channel is erected from the boards, which are divided in half.

- Then they equip the sealing, closing one of the channels with boards.

- Holes are drilled in the "sides" of the system for more efficient air circulation.

- When using such a ventilation system, the efficiency indicators will reach their maximum levels due to the volumetric air exchanges in the poultry house.

We suggest that you familiarize yourself with the Necessity and features of work when servicing ventilation

Forced ventilation systems are simple in design and easy to install. However, they are relevant only for buildings up to 20 square meters. Whether you need to use a mechanical system, or get by with the natural method - it's up to you. The main thing is to take into account the preliminary calculations and the individual properties of the poultry house.

The use of additional tools is also an individual desire. For convenience, you can use special sensors that will make the system automatic, turning on and off at certain humidity and temperature indicators.

Many poultry farmers are able to improve natural ventilation if the standard system is not working well enough. All that is required for the successful operation of the equipment is to place the fan in the hood window, and then connect it to the electrical network. But there is no need to doubt whether ventilation is needed in a flock for chickens or not. Such a solution is really necessary, since without a good exchange of air, the bird population can simply die.

Any poultry breeder can arrange ventilation with his own hands. The main thing is to carefully study the diagrams and step-by-step instructions, which will allow you to solve the problem in a short time and in the best possible way.

Pros and cons

With natural ventilation

- the construction will require a minimum of materials, tools;

- the action consists in the difference in temperature and speed of air masses above the elevated pipe;

- no need to supply electricity, and this is saving on wiring, power supply, additional devices for switching on and transmitting electricity;

- of the disadvantages - poor traction in case of calm weather or hot climates, when the temperature outside the shed is equal to or higher than the indoor microclimate.

For forced ventilation system

- its organization will contain exhaust and supply pipes, wiring, electrical devices for ventilation control, a mechanical fan;

- it will be necessary to supply electricity to such an outbuilding, which implies the inclusion of this fact in the documentation and will increase the cost of electricity;

- to work, you need to have a large set of tools and skills, since you will need to connect electrical appliances and a household network, if it has not been connected to the building;

- in case of poor natural ventilation or inappropriate weather conditions, good traction can be organized for the effective movement of air masses;

- the intensity of elimination of unpleasant odors and moisture is regulated by a person, which is more convenient.

Important When choosing the type of ventilation, they are guided by financial capabilities, available tools and knowledge in the field of electrical work, since mechanical ventilation copes with its task more efficiently

Ventilation system requirements

Dirty litter and ammonia fumes from excrement are unpleasant even for the farmer. What can we say about chickens who have to live in such conditions.

There are two main requirements for the organization of ventilation:

- it is necessary to provide constant access to fresh air;

- the equipment must be of high quality, otherwise it will have to be constantly repaired.

After installing the structure, you need to go into the room and stay in it for 20 minutes. A well-installed system eliminates unpleasant odor and stuffiness in the chicken coop.

If it is uncomfortable, stuffy, or a headache starts to be in it, then mistakes have been made.

Electrical devices

Mostly they can be found on large farms. The fact is that they are designed to work in rooms with a large area. However, an electrical air regulation system can also be installed in a conventional poultry house.

It will suit you if you keep a significant number of birds. If you don't have a lot of them, there is no need to install an electrical system. The level of energy costs will cover the level of income from keeping chickens.

- To install the device inside the house, it is necessary to calculate its perimeter and area in advance.

- Based on the data obtained, it is necessary to calculate the effective volume of air flows required to normalize the vital activity of birds.

- After making the calculations, you can get to work.

- For this, an electrical circulation system is installed at opposite ends of the walls of the house. An industrial fan must be installed in the wall.

- A pipe should be connected to the fan, the other end of which will go outside the house. When the fans are running, air flows will be circulated, the surplus of which will go through the installed pipes.

This method has a fairly high cost, so there is no need to use it in ordinary private houses. You can resort to simpler device methods. Their efficiency will be no worse than that of an electric air flow control system.

Remember that proper ventilation in the hen house in winter will increase the longevity of the chickens, improve their health and provide them with good living conditions during the cold season.

Existing ventilation methods

There are 3 ways to ventilate a poultry house:

- natural;

- mechanical;

- combined.

The first is the cheapest and is used when there are a small number of chickens. It is a simple ventilation, but it must also be arranged according to certain rules. Before deciding to make such ventilation in the chicken coop with your own hands, you need to take into account all the points even during the design of the bird house.

The second method of ventilation is more efficient, but simple to perform. If there are more than 20 birds on the farm, you should stop at this option.

Mechanical ventilation can be supply, extract or combined, i.e. supply and exhaust. It is arranged in large farms. The feasibility of using a mechanical system in a poultry house is determined by the size of the livestock - the house should be designed for a hundred or more chickens.

In a combined mechanical system, either the exhaust air mass is removed in a natural way, and fresh air is injected mechanically, or vice versa.

Typical ventilation arrangements and types are described here. We invite you to familiarize yourself with the principle of operation of typical options and the general rules for the design of systems.

Method 3 mechanical ventilation

This method is often called mechanical ventilation, but in reality it does not consist in using any mechanisms, devices or pipes for air circulation, but in a banal fan.

Mechanical ventilation with a fan

This method can be called mechanical because it involves special sensors to control humidity in the chicken coop. Their installation does not require serious costs, but can make the ventilation process of the room more efficient. The fan itself, ideally, needs to be installed in the window, then its profitability will be much higher. The third method involves an increase in the financial budget for ensuring the life of the chicken coop due to increased consumption of electricity.

In order for your chickens to be healthy, you need to take care of indoor ventilation. You can do this in any of the above ways. Do not neglect the issue of fresh air entering the chicken coop - birds have an elevated body temperature, so heat and moisture will constantly prevail. Poor ventilation can cause illness in chickens, a sharp decrease in egg production and the inability to eat their meat.

Types of ventilation used

There are many ways to ventilate rooms for keeping chickens, but let us dwell on the most common types: natural (exhaust and supply and exhaust) and mechanical.

With this method, the air circulation in the room is due only to physical laws.

When arranging the hood, air enters and is removed from the room using 2 holes: the door is most often used for admission, and a window is used for the exit. This option is not cost-effective, since heat will be removed from the building together with the exhaust air. Accordingly, in cold winters, you will have to spend more money on heating the chicken coop, and the removal of decomposition products is not efficient enough.

Natural way

There is also a supply and exhaust ventilation device in the chicken coop, which provides air exchange due to ventilation ducts or pipes, due to which air is more efficiently injected or removed from the room.

This option is provided by the operation of fans, which forcibly blow air into the building.

A simple way to install a supply fan

This method is more costly, since it is necessary to spend money on the installation of equipment and on the electricity consumed by it, but it allows you to completely get rid of harmful fumes.

Why ventilation is so important

Just like humans, birds need fresh air. Especially at that time of the year when frosts come and letting chickens go for a walk becomes problematic. The hood is necessary due to the fact that the waste products of birds can form in the air the so-called ammonia vapors, which have a bad effect on the organisms of layers. The carbon dioxide released during the breathing of chickens also contributes to the need for ventilation.

In order for ventilation in the chicken coop to be organized correctly, it is recommended to adhere to one of the three methods provided. A high-quality device will allow you not to worry about the health of the hens. Be careful when organizing the premises, this will allow you to protect yourself from further worries.

General information

In the hen house, as in every house, there are ammonia vapors, which are dispersed around the entire perimeter of the room. If there is no access to clean air from the outside, and toxic fumes are high, then chickens can often start to get sick, and in some situations this is the cause of mass mortality.

It is difficult to regulate air humidity without ventilation. Birds experience the same discomfort in both very dry and very wet chicken coops. This issue becomes all the more relevant in winter, when all the birds are in a closed room all the time. The air accumulates water vapor, carbon dioxide and ammonia emissions, which are formed from the droppings. The decaying substrate on the floor and the food on it is an ideal basis for the development of pathogens.

Just leaving the doors open is no way out. This option for providing clean air can cause another serious problem - scallop frostbite. For chickens, a draft and a sharp change in temperature are dangerous. Therefore, making the right ventilation in the chicken coop is a very topical issue for any poultry breeder.

Types of chicken coop ventilation systems and their installation

There are several ways to equip the house with ventilation:

- Natural. This design works due to the movement of air due to the temperature difference inside and outside the room.

- Forced. In this case, the system is operated by the fans.

Let us consider in more detail the schemes, the principle of the design and installation of ventilation with our own hands in the hen house in winter.

Natural

This ventilation option will be convenient for chicken coops with a small number of chickens due to the ease of installation. The construction of the system does not require any financial costs and additional devices, for example, a fan, filter, etc. For the manufacture of the system, a small ventilation window must be provided in the wall. It is best to place it above the perches. Thus, when the door is open, air will flow out the window.

To be able to regulate the air flow, the ventilation window is made in the form of a window.

However, this method has a significant drawback: in winter, a heater will have to be installed in the hen house, and in summer there will be no ventilation as such due to the absence of a temperature difference between the outside and the house.

Supply and exhaust

If you listen to the opinion of experienced poultry farmers, ventilation of the supply and exhaust type is the most effective in operation. This system can be used in winter. In order for such a ventilation scheme to work without electricity and drafts, it is recommended to watch a video on this topic.

In contrast to the option considered above, the supply and exhaust ventilation is structurally provided with two pipes - for the air inlet and outlet.

This method has several significant advantages:

- work does not require human participation;

- no electricity costs;

- the system operates silently and does its job perfectly.

To make this version of the hood you will need:

- plastic pipes with a diameter of 150 mm and a length of at least 2 m;

- jigsaw;

- plugs for pipes;

- 2 pass-through nodes;

- caps for pipes.

To establish ventilation, measure the height of the house. Then 2 holes are made in the ceiling along the diameter of the ducts. The exhaust pipe is mounted near the perches for better removal of ammonia vapors. The installation is carried out under the ceiling and taken out into the street so that the pipe protrudes 1.5 m in height.

The pipe for the air supply is installed at a height of 40 cm above the roof and lowered almost to the floor. The distance between the floor and the pipe should be about 40 cm.

To make the structure airtight, pass-through nodes are used, and the pipes themselves are fixed to the roof with stretch marks. Air ducts protect from precipitation, and plugs are adapted as dampers.

Mechanical

In most cases, large poultry houses are equipped with such a system, in which the supply and exhaust system will simply be ineffective. Ventilation works by analogy with the previous version, with the only difference that fans are used. The use of fans will incur energy costs, which must be taken into account in advance. If there is a power outage, there will be no ventilation and air stagnation will occur.

The principle of operation of mechanical ventilation is quite simple and boils down to installing a fan in a window, wall or chimney. This type of air exchange has the following advantages:

- a large chicken coop can be provided with fresh air;

- the functioning of the system is not affected by the weather;

- when installing climate control, human participation in the operation of the system is not required.

Manual option

For installation, a fan is used, which is installed in the exhaust pipe. Then they lay the electrical wiring and fix the switch near the door.

The wiring must be carefully insulated as the humidity in the house is always slightly overestimated.

The peculiarity of this version of the hood is that a person controls its work. Depending on the microclimate in the room, the device is turned on for 2-3 hours a day.

Auto

This ventilation option does not require human intervention. Despite the fact that the system is of a mechanical type, manual control is completely excluded.

Installation consists of the following steps:

- Air supply and exhaust are made of two plastic pipes with different diameters and lengths, according to the area of the house.

- Lay the wiring to the fan. If a supply unit is installed, then the fan is installed in the supply pipe.

- A switch is fixed to the wall.

- Sensors are used to control the system. When the desired value of humidity and temperature is reached, the automatic system is triggered and the system is turned off.

Poultry breeders' recommendations

As an inexperienced poultry farmer, there is always the possibility of making a mistake when installing ventilation equipment. If the coop cools too quickly, or vice versa, there is no ventilation, then the system was incorrectly thought out and installed.

At the planning stage, you need to correctly position the pipes so that the air exchange takes place inside the room.

You can evaluate the efficiency of the ventilation system as follows: go into the poultry house and stay in it for some time. If during this period the state of health is normal, then the ventilation system works well. If this is not the case, then it will be necessary to make improvements to the design.

When equipping the ventilation system with fans, it is recommended to use sensors that will save energy. This option will also be more appropriate in poultry houses where fermentation bedding is used, as the bacteria generate a significant amount of heat: higher temperatures can negatively affect poultry health.

Based on personal experience and mistakes of poultry farmers, problems in the installation of the ventilation system are indicated by:

- ventilation holes are located on adjacent walls. With this arrangement, there is no air exchange in the opposite part of the room, since the air is not able to circulate at right angles. In a rectangular chicken coop, it will be correct to install ventilation holes on the sides with a shorter length opposite each other;

- noise during operation of the fans.The functioning of the devices must be checked before installation, because due to the increased noise in chickens, egg production may decrease or even stop;

- low structural reliability. Equipping a large poultry house with a ventilation system, metal air ducts are fixed to the ceiling. Since chicken coops are often built of wood, the material can rot relatively quickly, leading to the fall of the air ducts. Based on this, it is advisable to carry out the installation of metal structures to the rafter system;

- if metal pipes are used for ventilation, they must be thermally insulated in winter. If this is not done, the chicken coop will be very cold even with the valves closed, and the constant formation of condensation can cut off the air supply.

In order for the hood to work effectively in the hen house in winter, you should adhere to simple recommendations:

- periodically clean the premises from droppings, dirty water, and remaining feed. A clean chicken coop is the key to a healthy bird;

- check the house for rodents and take action to eradicate them. Extraneous animals can be the reason not only for a decrease in egg production, but also for the appearance of diseases in chickens.

Having considered the purpose, possible options, as well as step-by-step instructions on how to properly ventilate the hen house in winter with his own hands with diagrams and photo examples, everyone will be able to equip their own house without significant time and financial costs. Only with proper ventilation and maintaining a comfortable microclimate can you get high egg production and healthy offspring.

Similar publications

- To read

How to make ventilation in the bath

- To read

How to make roosts for chickens

- To read

How to make candy for bees in winter

- To read

How to heat a chicken coop in winter

- To read

Hare trap in winter

- To read

Safety first

A mandatory ventilation system is necessary not only to maintain the health of the kept birds and create the most comfortable living conditions. Of course, well-thought-out and properly designed room ventilation can achieve amazing results. However, the most important task of the ventilation system is to ensure the safety of human health.

Chicken manure contains large quantities of ammonia, a dangerous gas with an unpleasant odor that can cause poisoning. With the accumulation of a sufficient amount of droppings, the concentration of ammonia can exceed the permissible norm. Excess gas has a negative effect on the immunity of poultry, which becomes vulnerable to various viruses and infections. Consuming meat from infected broilers can lead to serious health problems. In a spacious chicken coop, not equipped with a gas exhaust system, even if it is regularly cleaned of droppings, a dangerous ecological situation is gradually created.

We recommend that you familiarize yourself with: Disinfection of ventilation systems