"Livestock" Cows and bulls "Features of building a cowshed with your own hands

0

533

Article rating

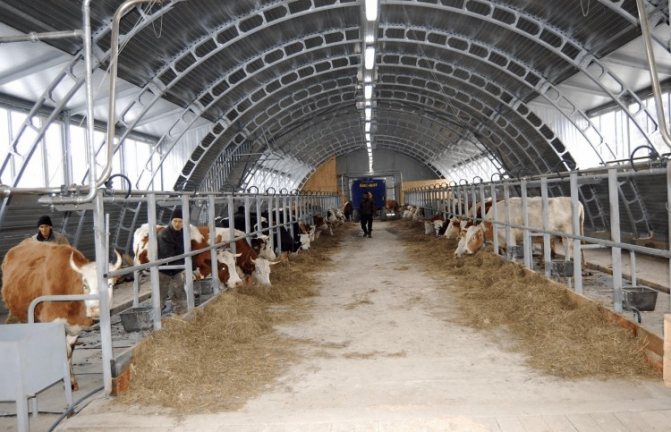

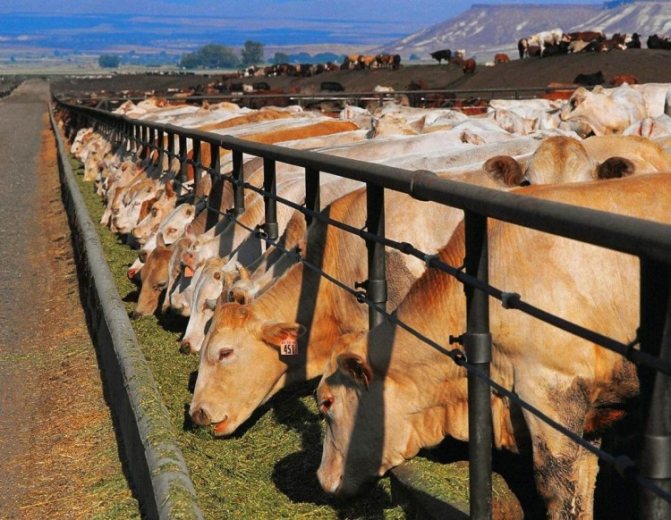

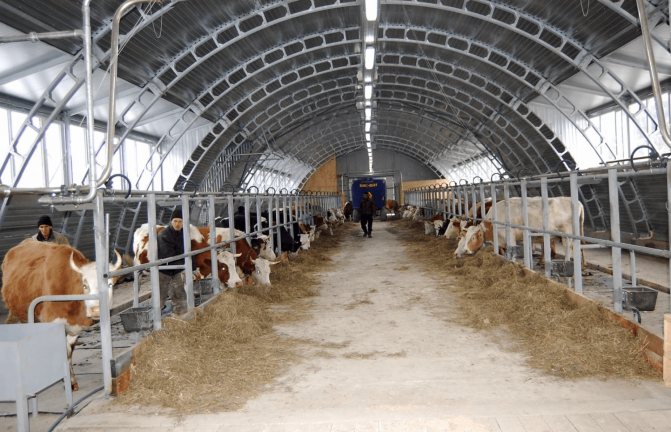

Before you start cows, you need to take care of the availability of housing facilities. If the construction of a large-scale farm designed for 400-500 heads cannot be carried out independently, then building a cowshed with your own hands for a small number of heads is a feasible task.

You can build a cowshed with your own hands for a small number of heads

Calculations, dimensions and features of the barn.

Before building a cowshed, one should take into account sanitary standards, which state that such premises should be built 15 meters from a residential building, and 20 meters from wells and wells.

It is not recommended to build a house for cows closer, it is not recommended, you can certainly build a barn closer, but at the same time in a residential building you can smell the smell from animals, and drinking water can be contaminated with waste from animals.

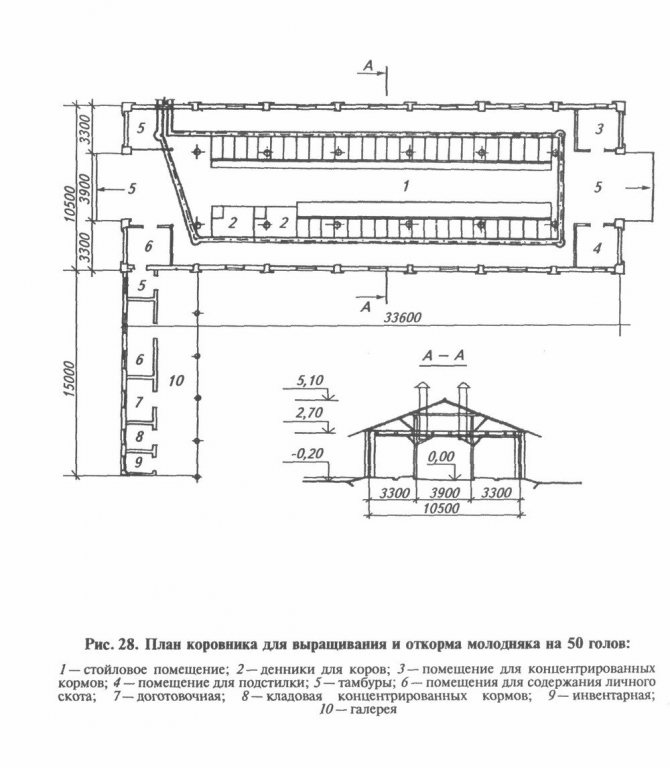

After choosing a place, the dimensions of the future structure are planned, the plan is made based on the number of cows, for one cow you need at least 6 square meters, and preferably all 10. The height of the barn should be at least 2 meters, but not more than three meters.

If it is planned to keep several animals, then a passage should also be provided between the stalls. It is usually placed between the wall and the stalls, or in the center of the barn, with a minimum width of 1.2-1.5 meters.

The plan should provide a place for a utility room, and if there are many animals, then a room for isolating sick animals.

For a more complete understanding of the whole picture, you should draw up drawings of the barn with your own hands, sign on them all the necessary dimensions, numbers and explanations.

Typical design device

First things first, remember one rule: cow comfort comes first. This is the only way to get good quality meat and dairy products and recoup your costs. Regardless of the livestock, a comfortable barn consists of the following sectors:

- stalls with a feeder, drinker and waste disposal;

- food storage room (kitchen);

- delivery area for newborn calves;

- playground for walking animals;

- utility room for storing inventory;

- manure collection area;

- compartment for storing milk, as well as keeping milk containers;

- boiler room for heating all rooms.

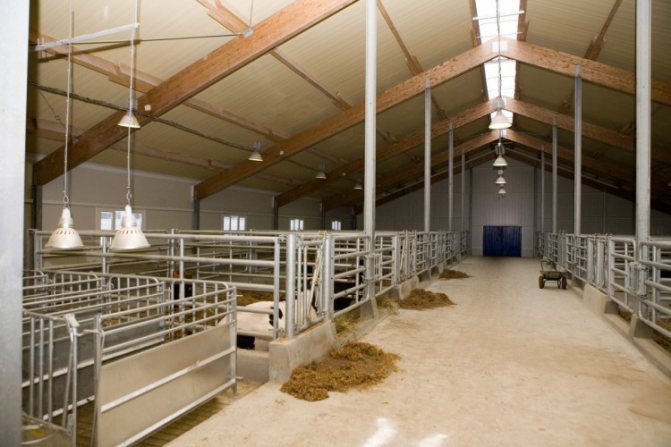

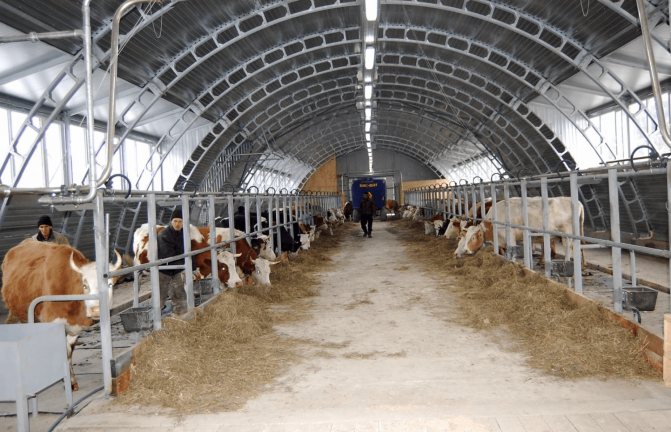

Stalls are arranged in rows depending on the number of heads. In an individual farm, there are mainly single-row rooms, two-row or three-row.

There must be enough free space between the stalls

Animals should not be cramped, therefore, the passage between the rows is made moderately wide.

Types of barns

How productive the farm will be depends on the right choice of the barn. Many factors are taken into account here: the separate keeping of heterosexual animals, the proportion of young animals, the number of heads, etc.

For small farms with a maximum of 50 heads, as a rule, mini-cowsheds are built - pre-fabricated frame hangars, well-lit and ventilated, which are warm and cold.The latter are more suitable for cattle, as cows, calves and gobies feel better in cool buildings (with outside temperatures). In such conditions, they get sick less, develop better and give more milk yield.

It is more appropriate to build frame hangars in regions with year-round warm weather conditions.

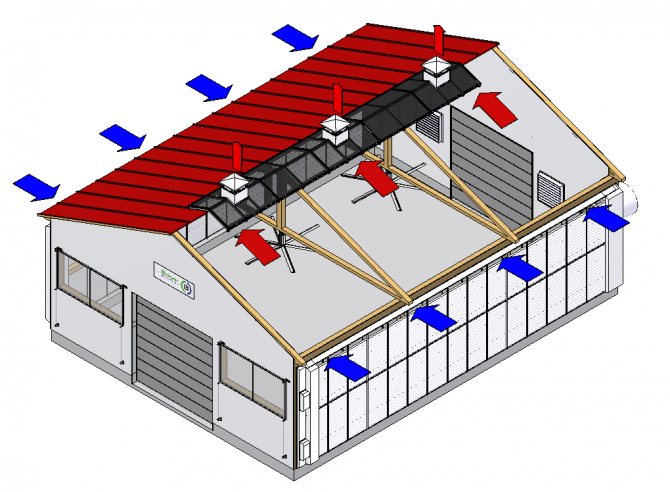

Unfortunately, in most regions of our country, severe weather conditions do not allow keeping animals in cold barns. We have to build insulated barns with a large number of windows that are constantly kept open, which provides a suitable microclimate for the animals. However, when keeping more than 30 cows, you already need to take care of additional ventilation - install fans or polyurethane ventilation curtains, light aeration skates or Frivent DRW ventilation unit (if finances permit).

Additional ventilation avoids excess moisture and regulates temperature conditions

Although there are many varieties of barns, any of them should be cool, light and cozy.

According to the materials used in the construction of cowsheds there are:

- in the form of buildings made of metal profiles, with a room temperature close to the outside temperature;

- as buildings made of thermal insulation building materials;

- type of hangars made of sandwich panels.

Basic design:

- 2 + 2-row cattle house for free keeping of animals (loose) with a high trapezoidal roof made of metal profiles with a minimum number of beams, which will ensure good air exchange;

- 3 + 3-row for the joint housing of dairy cows with calves and a separate milking parlor;

- 3-row barn, where the calf section and the milking area are in the same room;

- The 4-row barn makes it possible to fully mechanize all work - milking, distributing water and feed, removing manure.

Video: supply and exhaust ventilation of a cowshed for 200 cows in the Irkutsk region

The choice of material for construction

The choice of the material from which this outbuilding will be built is determined not only by the climatic conditions of the area, but also by the desire of a person to make a strong and reliable structure.

A more durable barn is obtained from bricks, gas silicate blocks. But this is not a very suitable material for this room, since impurities may be present in the gas silicate blocks, which can subsequently have a negative impact on the health of animals.

And in a barn made of stone, it is possible that high humidity occurs and it can be quite cold. This is partially solved by arranging good ventilation, and arranging additional heating.

Usually, ventilation in the barn with your own hands, as well as heating, are planned and done in conjunction with the construction of the barn.

The ideal material for the construction of walls is adobe brick; for heat inside the barn, a wall thickness of only one and a half to two bricks is sufficient. You can also build a cowshed with ordinary bricks. Such a barn will be durable and will stand for a long time.

But still, the most popular material for the construction of this structure is wood. Wood has low thermal conductivity, it keeps heat well, but at the same time, a barn made of wood is not particularly durable.

Stall for cows

The cow stall is designed taking into account the individual characteristics of the animal and the characteristics of the breed. For example, stalls for beef cows should be larger than for dairy cows.

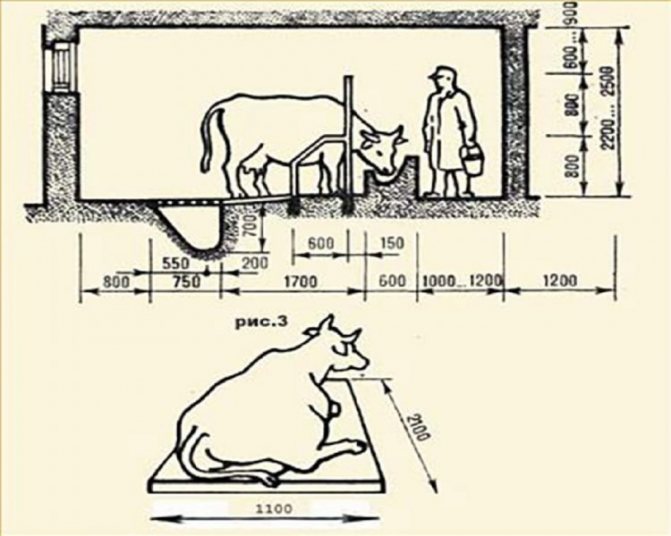

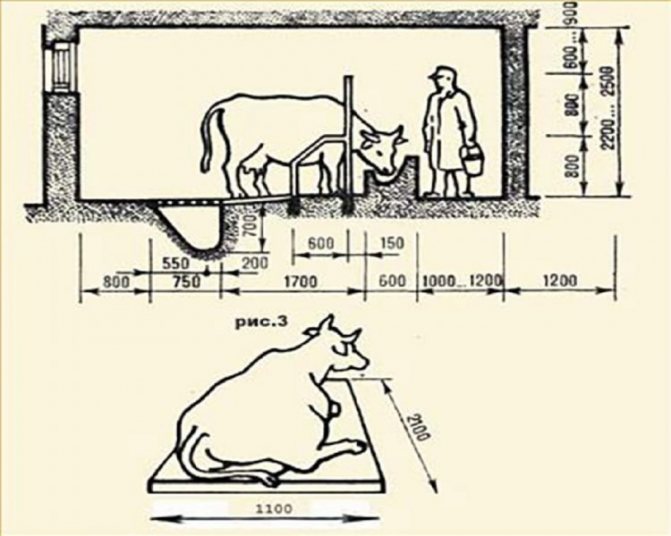

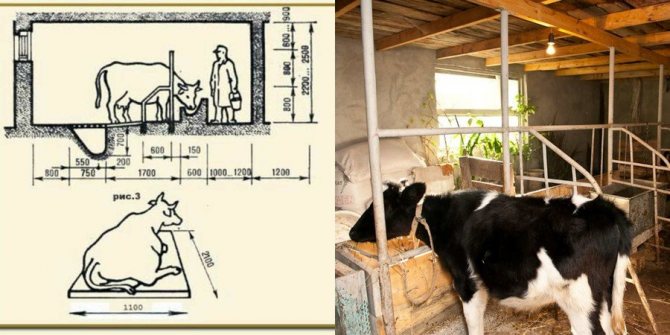

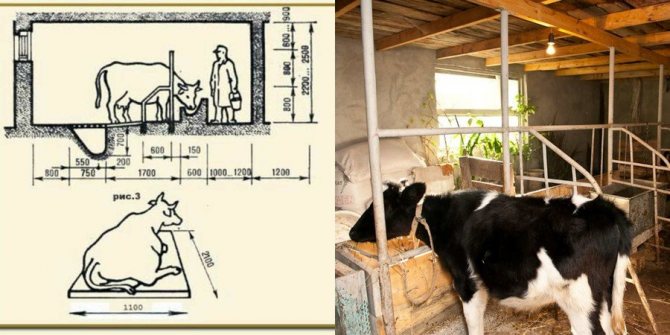

Figure 7. Dimensions and drawings of the cow stall

In a home garden, a stall can be made from boards or metal pipes. In some cases, the stall is built of bricks, but such structures are impractical as they cannot be moved to another location.

The average stall width is 125 cm.A narrower cow will be cramped, and if the stall is wider, the cow can turn to face the gutter and the feeder will become contaminated with feces. The length of the structure is 260 cm, but for large cows it can be increased up to three meters. Drawings for the construction of a cow stall are shown in Figure 7.

When keeping beef and pregnant cows, the stalls are increased in length and width, therefore it is better to make the structures mobile so that, if necessary, the dimensions of the stall can be arbitrarily changed.

You can find more information about the size of the stall and the keeping of the cows in the video.

Floor arrangement in the barn

The floor should be given special attention - the easiest way is to make it from 5 cm thick wooden planks, but such floors will have to be completely replaced after a few years. Wood under the influence of ammonia, manure will begin to decay rather quickly, besides, wood actively absorbs all odors.

You can make a floor in a barn with your own hands from concrete, but such floors are not recommended in a barn, since in the cold season such floors accumulate cold well and animals can get sick.

If the floor is made of concrete, then each stall should have a thick layer of sawdust or straw bedding. You can also put special wooden shields on the concrete floor, which, as they wear out, change to new ones.

The floor should be made with a slight incline so that urine and slurry can drain into a pre-made tray. The tray is usually 25-30 cm wide and 10-15 cm deep.

Feeding cows: norms, daily ration, additives, feeding and advice on choosing the composition of the feed (110 photos)

Insemination of cows: types, recommendations, description of technology and step-by-step instructions for artificial insemination at home (130 photos)

Cow meat: composition, properties, characteristics and features. Tips for raising cattle and producing beef (120 photos)

A little about feeders

For the manufacture of feeders, oak or pine boards are usually used. It is very important to have well dried wood to avoid its rapid decay. In addition, the material must be well sanded so as not to injure the lips and tongue of the animals.

It is important to make the feeder in such a way that not only is it convenient for the animal to eat from it (although this is a primary condition), but also that it is convenient for the worker to clean the box, as well as put new food into it.

Farm Feeders

Outwardly, a standard cow feeder resembles a medium-sized box, which is placed next to the animal's head on the floor. By type of feeders can be:

- lifting;

- motionless;

- folding.

The fixed option is most often chosen, although lifting or folding are more suitable for small barns, which save space. In addition, the folding version is more convenient for cleaning.

Attic, roof and barn arrangement

If the barn is large enough, then a gable roof should be made, such a roof, unlike a pitched roof, will perfectly hold the snow load.

And if a ceiling is made in the barn, and a gable roof is installed on top, then the resulting attic will serve as an additional insulation.

A pitched roof with a slope to one side is also suitable for a small barn. The roof is closed from above with roofing material (its service life is not long), slate or iron.

Lighting needs to be laid inside the barn, if only light is needed, then the wire can be carried out from the house. And if any additional auxiliary mechanisms are installed that require a lot of energy, then in this case a separate line should be laid into it.

Dairy farm business plan

The most demanded food product, which is also very useful for the body, is milk and various products based on it. Dairy raw materials are also widely used in the food industry. That is why the number of new dairy farms is growing, and the state financial assistance helps the development of the farm. If an entrepreneur decides to open his own business in this direction, he will need to understand what a dairy farm business plan is and draw up it without missing a single moment.

Diy cowshed photo

Manure storage

The manure storage is one of the key buildings for keeping cattle. This building helps to store the manure and turn it into humus.

The most efficient system for manure removal is the use of a rod-scraper mechanism, which can work in both the longitudinal and transverse directions. The main structural element of this mechanism is a bar with scrapers, which are attached to it and have a floating stroke. Scrapers are made of cast iron steel. The rod is very practical in operation and durable in operation, and also does not require frequent repairs. The design of the manure removal system is effective due to the fact that each line has an individual mechanical energy-saving drive and allows you to start a specific line as needed. Manure removal from the barn can be carried out at the end or middle of the yard.

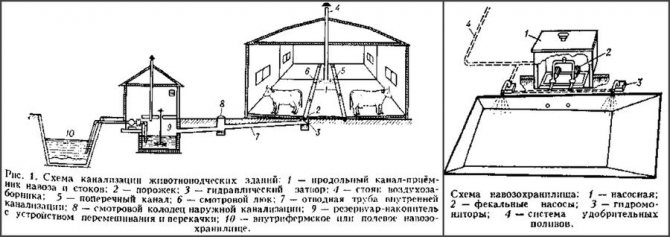

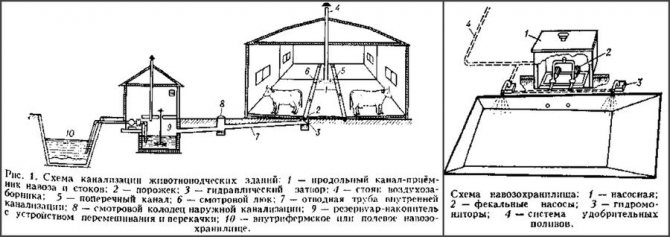

Figure 9. Schemes for the arrangement of manure storage

The manure is transported from the central canal by means of a screw conveyor to the manure collector, which can hold a three-day volume of manure.

When building a manure storage facility, it should be borne in mind that a cow can produce about 12 tons of manure in one year. The amount of manure is influenced by the feed ration, volume and type of litter (Figure 9).

For a cattle yard, a manure storage with dimensions of 2.5 * 2.5 m will be satisfactory, which must be built next to the barn, the walls of which must be overlaid with stone. The pit for the manure storage is dug out at a depth of about half a meter. In the presence of a high level of groundwater, the manure storage is built directly on the surface of the earth. In an area with sandy soil, about a 30-centimeter layer of clay should be laid on the bottom of the pit. The perimeter of the pit is arranged with a stone laid out on a cement mortar. The bottom of the manure storage should be made with a slope in the direction of the slurry collector to drain the collected slurry. A canopy is made from above. The manure is laid very tightly to a height of up to 2 m, after which it is covered with layers of fine straw or peat with a thickness of 15 cm; it is also necessary to regularly watered with water or slurry.

Next to the manure storage it is necessary to arrange a slurry well, having coated its bottom and walls with clay. In order for the urine to drain into the well, it must be located directly near the wall of the building below the level of freezing of the soil in this area. Also, such a pipe is taken out into a slurry well and a manure storage. The top of the well is covered with a wooden or metal shield.

To drain surface water around the entire perimeter of the manure storage and slurry well, grooves are dug, which are designed to drain liquids into the collecting well.

Closed type manure storage

The design of the manure storage is determined by the climatic conditions of the region. In areas with a large amount of precipitation, it is more rational to build a closed-type manure storage. These are large tanks or barrels into which manure is fed through gutters or pipes.

The closed type of manure storage has one significant advantage: the slurry rotts faster without loss of nitrogen, and the resulting humus is used to fertilize plants.

Open type manure storage

It is easier to equip an open manure storage in a home farm.To do this, it is enough to dig a pit, concrete it or cover the walls and the bottom with a film. This will prevent manure from penetrating deep into the soil and groundwater.

You can put slurry in an open storage simply with a shovel (in small farms) or through pipes if the farm contains a large number of cattle. In order for the manure to quickly turn into humus, it is recommended to mix it periodically so that the upper layers are at the bottom.

From the video you will learn all the information you need to know about building a barn from scratch.