When planning the breeding of pigs, it is necessary to take care of the premises in which the animals will be kept. For quick weight gain, they need a lot of space, but if the farm will contain only a few heads, you can convert part of the barn into a pigsty, although it is much better to equip a separate room for this purpose.

In this article, you will learn how to properly build a pig shed with your own hands. The article provides detailed instructions for self-construction, as well as photos and drawings of simple but functional projects.

- Laying the foundation

- Finishing work

Options and materials for thermal insulation

How to insulate a barn with your own hands? First of all, you need to choose the technology and material. The following materials were traditionally used for thermal insulation of outbuildings:

- Chopped straw. This insulation has been used by people for thousands of years. It is highly ecological, but short-lived. Straw is flammable, prone to getting wet and rot, insects and rodents willingly start in it. In order to protect the material, it is impregnated with lime at the rate of 1 part of lime to 25 parts of straw. The resulting mixture is filled in the space between the two plank walls. Straw is also used to insulate the ceiling. The thermal insulation coefficient of straw is low.

- Sawdust. Sawdust, like straw, is also flammable and subject to biological hazards. They are mixed with lime in a 1:15 ratio. To strengthen the composition and increase its moisture resistance, add up to 10% of cement. Sawdust is prone to caking; in case of wall insulation, they will have to be added annually.

- Expanded clay. These are light pellets with a diameter of 1-2 cm, sintered from ceramic raw materials. The material is not hygroscopic, durable, not flammable, little caking. It is also not susceptible to biological threats. The only drawback is low thermal insulation values, forcing the use of thick layers of material. When backfilling expanded clay between the walls, it is often mixed with cement mortar. It turns out to be a very durable material. This should be done in layers of 20 cm, each time giving the solution time to set. Otherwise, the lower part of the wall may expand.

Expanded clay - a material for insulating a barn

Nowadays, more modern materials are increasingly used to insulate sheds. They are more expensive, but have several times higher performance. Among them are:

- Foam glass. Small foam glass granules. Does not burn, does not get wet, does not allow the development of mold, microorganisms or rodents.

- Mineral wool. The product is made from rocks (basalt wool) or from glass waste. The material does not burn, is not subject to bio-threats. Possesses high rates of thermal insulation, for example, a layer of 50 mm of mineral wool is equivalent to a 25-centimeter layer of sawdust. Mineral wool is mounted in a guide system. It is suitable for insulation of both walls and ceilings.When wet, the material loses its heat-insulating properties, therefore, during installation, special attention should be paid to waterproofing and steam removal. During the installation of the mineral wool, it emits dust harmful to health; it should be worked with in protective gloves, thick clothing and shoes, and in a respirator.

- Expanded polystyrene. The common name of the material is polystyrene. It is produced in sheets with a size of 100 * 100cm, it can be easily mounted on vertical and horizontal surfaces. It has good thermal insulation, does not absorb moisture. One of the main disadvantages is fragility. When pressed firmly, the sheets crumble, so care must be taken when handling them. Another significant disadvantage: the material is flammable; when heated, it emits poisonous gases and aerosols. This limits the use of foam for the insulation of residential premises.

- Extruded polystyrene foam. It is extruded and has a significantly smaller granule size than conventional foam. The material is durable, does not crumble, does not need additional vapor and waterproofing. Ideal for thermal insulation of floors.

- Polyethylene foam. The common name is penofol. This flexible and resilient roll material is covered on one side with a layer of foil that reflects heat back into the protected area. It is used as a waterproofing and additional insulation, or as a main heat insulator. Easily mounted on wooden surfaces with a construction stapler. The material also emits harmful substances when heated. The widespread use of penofol is limited by its high price.

In addition, progressive spray materials such as polyurethane foam and ecowool are becoming more common. The high cost of the equipment makes it unlikely to purchase them specifically for the barn. However, if they carry out thermal insulation of the main house, and the equipment has already been brought to the site, then the remnants of materials are quite realistic to use for outbuildings. The sprayed materials do not have seams and create a perfectly even continuous layer of thermal insulation. They do not cake, do not crumble and are characterized by consistently high thermal insulation properties and durability.

Do-it-yourself barn insulation technology

How to insulate a barn? The technological process is not complicated. It does not require highly skilled workers and the use of expensive equipment. General construction skills are quite enough to complete the work; the owner of the shed can do them with his own hands. He will be required to be accurate and strictly follow the technological recommendations and safety rules.

Materials and fixtures

To insulate the barn with mineral wool or foam, you will need:

- insulation;

- wooden lath or metal profile for guides;

- waterproofing film;

- vapor barrier membrane;

- Double-sided tape;

- polyurethane foam;

- assembly knife;

- screwdriver;

- jigsaw or circular saw;

- self-tapping screws;

- measuring tool: tape measure, ruler, square, level.

To insulate the barn, you may need a waterproofing film.

It is also necessary to equip the workplace for cutting the material indoors or under a canopy. It should be spacious and level and well lit.

Wall insulation

The method of wall insulation depends on the selected material. If you decide to work with bulk insulation, such as sawdust or expanded clay, you will need to build a second wall at a distance of 10-15 cm from the main wall of the shed, connected to the main wooden vertical logs. The boards of the second wall are allowed horizontally, nailing them from the bottom. Every half a meter of height, you need to make a stop, fill up the insulation flush with the top board and tamp it.

If sheet material, mineral wool or penoplex is selected, proceed as follows:

- a waterproofing film is attached to the outer wall from the inside;

- further, wooden planks or a metal profile of the guides are vertically fixed to the wall;

- insulation sheets are laid between them;

- slots and gaps are tightly clogged with scraps or blown out with polyurethane foam;

- on top of the insulation along the guides, a vapor barrier membrane is attached.

Now you can fix the inner cladding made of thin boards, plywood, OSB or moisture resistant gypsum plasterboard.

Floor insulation

The budgetary way to insulate the floor is as follows:

- knead chopped straw with clay;

- apply clay on the floor with a layer of 10-15 cm, level and tamp.

From above, such a floor is sprinkled with sawdust or straw, which are periodically changed. For goats and sheep, it is recommended to make beds with a height of 20-30 cm from the floor level, animals willingly spend the night on them and do not freeze.

Straw with clay - a way to insulate the floor in a barn

A serious method of floor insulation involves sampling soil to a depth of 30-40 cm, backfilling expanded clay there, and making a clay or cement screed. Wood floors are used less frequently in animal housing. They are insulated with polystyrene or polystyrene foam. Mineral wool is not used, as it will inevitably get wet from urine and water spilled from drinking bowls.

Ceiling insulation

Up to half of all heat losses pass through the ceiling.

To properly insulate the ceiling, you need to proceed as follows:

- a vapor barrier is spread over the rough floor, for this you can use a plastic film, roofing felt or a special vapor barrier membrane.

- insulation is laid on top of the vapor barrier on the rough ceiling: sawdust, straw with lime or expanded clay;

- from above it is closed with a waterproofing layer.

If a rough ceiling in the shed is not provided, the sheets of foam insulation are attached directly to the roof lathing using disc dowels and an adhesive.

Spraying polyurethane foam on the roof from the inside is very effective.

We insulate the doors

If the door is an uneven opening in the wall, somehow closed with a slit sewn from a slab on rope hinges, it makes no sense to insulate such a “door”.

You will need to install a normal door frame, seal the gap between it and the doorway with polyurethane foam, and hang a solid wood door.

The door leaf can be upholstered with penoizol 6-8 mm thick. This will double the door's ability to resist cold. The porch is insulated by gluing strips of foam rubber or a sealing rubber profile around the perimeter of the frame.

Windows are also insulated in the same way. To preserve heat, old windows are tightened with polyethylene, pressing it against the wall with glazing beads.

Features of building a shed for pigs in the country with your own hands

Before building, everything should be carefully calculated. This will help the answers to the questions:

- The number of livestock that will be kept in the building.

- The financial and physical capabilities of the owner.

- Site of future construction.

- Necessary materials.

- Possibility of summarizing communications.

It is necessary to correctly calculate the size of the building, because excess space will affect the financial side, and if there is a lack of it, animals will suffer. The benefits of pig breeding as a business, this article will tell.

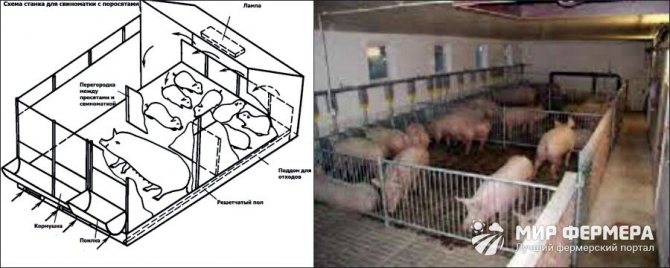

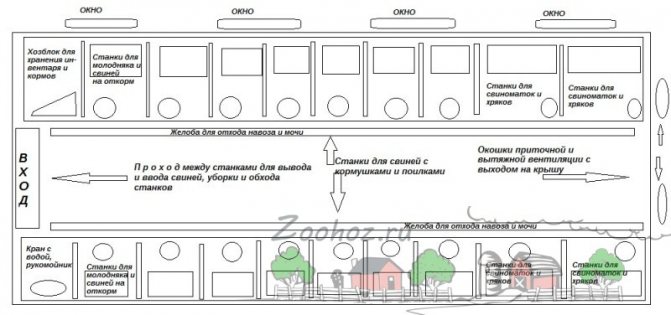

Pigsty construction scheme.

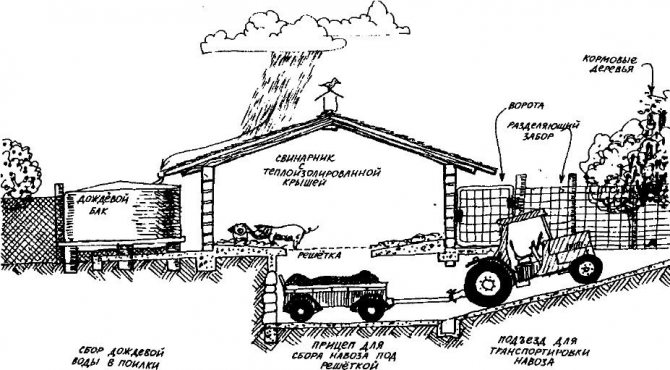

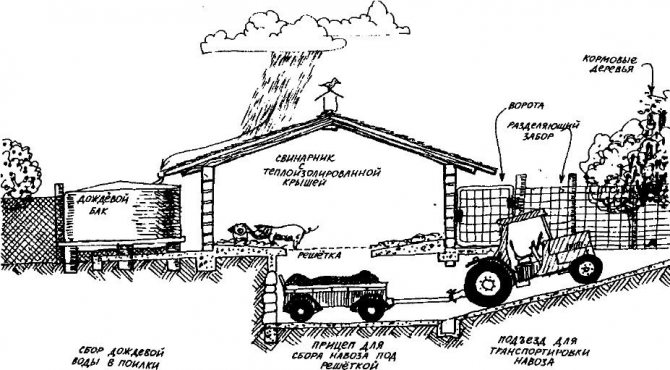

If possible, you should make a barn with a corral. This allows you to safely walk the animals in the warm season.

Choosing a construction site

The place of the future pig shed must comply with certain standards:

- The pigsty should be located more than 12 m from the house and 4 m from the border of the plot.

- When building, you should take into account the direction of the wind prevailing in your place of residence. This will relieve you of the constant, strong smell of pig waste.

- The structure should be located in such a way that it is easy to clear manure heaps, deliver food and drink for animals.

- The barn should be located on a hill. Then the premises will remain dry, and the walls - clean from the fungus.

The pigsty should not be located in swampy areas or in places where moisture often accumulates.

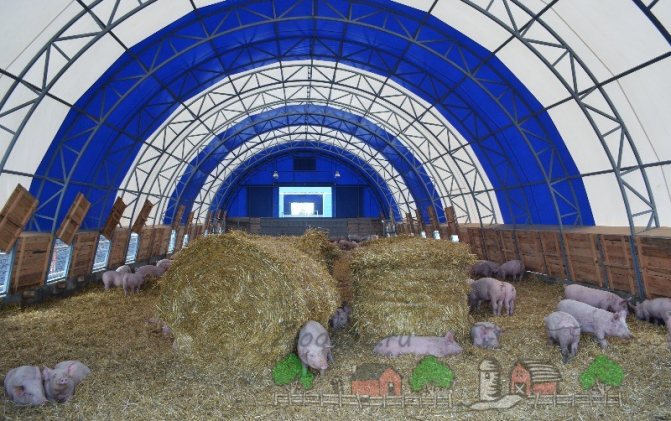

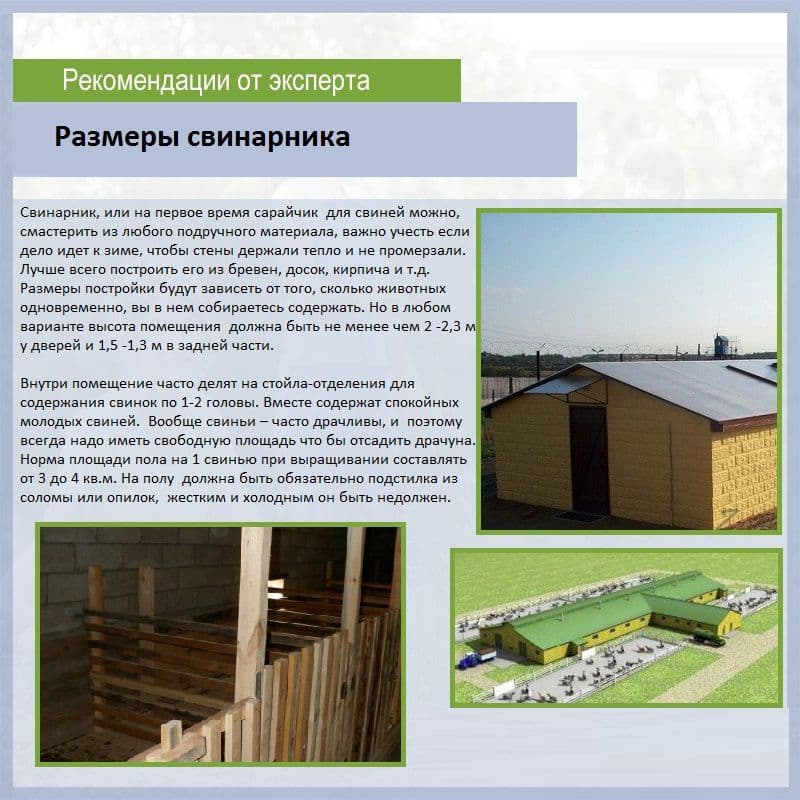

Choice of materials

When pig breeding at home, almost any material at hand can be used to build a barn. Preference should be given to building materials that can retain heat, because pigs are very thermophilic animals. The most common such material is wood. It retains heat well and allows air to pass through. If possible, you can build from bricks and cinder blocks, with internal sheathing with wooden planks.

In addition, for construction and insulation, you can use:

- expanded polystyrene;

- silicate blocks from aerated concrete;

- mineral wool.

During construction, concrete should not be used, because it has a high thermal conductivity.

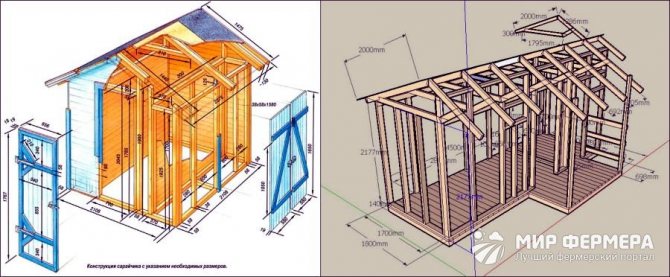

Sizing and design

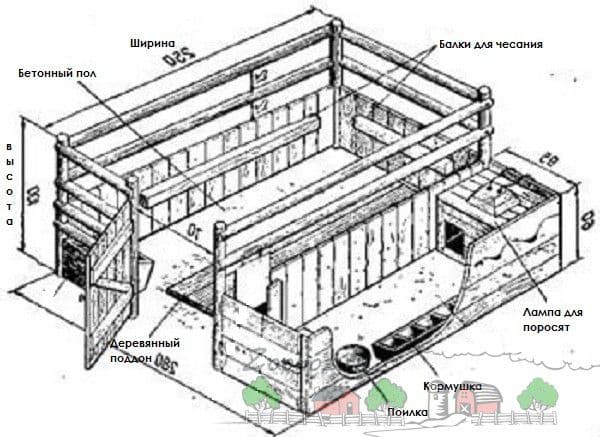

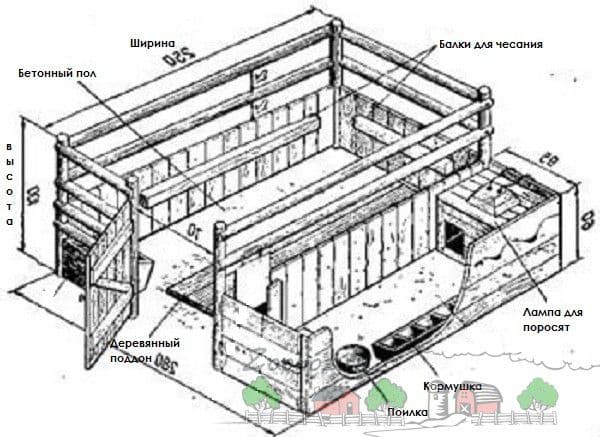

At the beginning of construction, you should decide on the number of animals that will live in this barn. This will allow you to design premises with all communications, convenient for use by animals and owners. The average area required for keeping one pig is 5 sq. M. When calculating the total area of the building, it is necessary to take into account some features:

- Animals raised for slaughter can be kept in single pens or in groups.

- In case of group keeping, the space for one individual should be at least 0.9 square meters.

- The number of animals in the general section should not exceed 25 heads.

- Boars and sows should be kept separate. Their sections must be at least 4 sq.m.

You can find out how to build a pigsty for 50 heads with your own hands.

With the constant keeping of pigs, you should equip a walking area next to the barn. The area of the required space can be calculated, taking into account that for boars and sows you need 10 sq.m. space for one animal, and for a herd at the stage of fattening - 1.5 sq.m.

Estimated costs

The cost of a pig shed can be calculated by considering the following factors:

- Number of livestock. More animals require more space and inventory to care for.

- Content type. Breeding and slaughter sheds have some differences.

- Materials for manufacturing. The total price of a building directly depends on the cost of building materials.

- Season. Summer sheds are easier to build and cheaper, winter sheds are more durable and costly.

- Equipment. The interior decoration of the premises and the equipment for caring for animals significantly increase the cost of the pigsty.

Self-production of a barn significantly saves money and allows you to design a structure in a way convenient for you.

This video tells about the device of a pigsty with maximum automation at home.

- Proper housing makes it easier to care for and maintain the animal.

- Do-it-yourself pigsty, you can build it yourself from most of the available means. You should not save on building materials - this will only lead to problems in the future.

- Temporary housing is much cheaper and faster to build... However, if you keep pigs all year round, you need to build a reliable and durable barn. Over time, these costs will pay off.

- Houses for different types of animals have specific featuresthat should be considered during construction. This will make the life of the animal and the work of the owners easier.

The benefits of pig breeding as a business, this article will tell.

How to build a pigsty with your own hands

You can build a shed for pigs yourself using available tools.However, if you want the building to be comfortable and to last for a long time, you should take into account some features during construction.

- The barn should have wide, comfortable walkways and approaches to the pens.

- The building must have a good ventilation system, drainage and lighting.

- Everything in the building should be made of sturdy material that can withstand the power of a pig.

- The roof of the shed and corral must be positioned at an angle, which prevents the accumulation of precipitation.

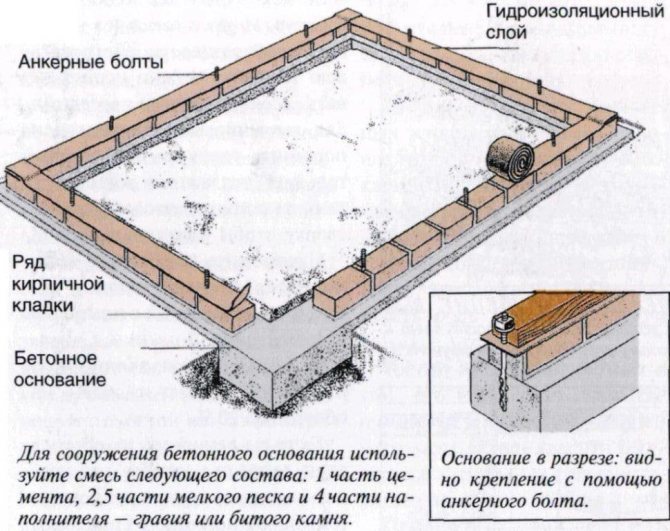

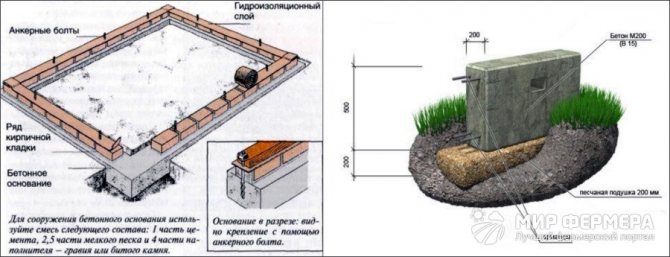

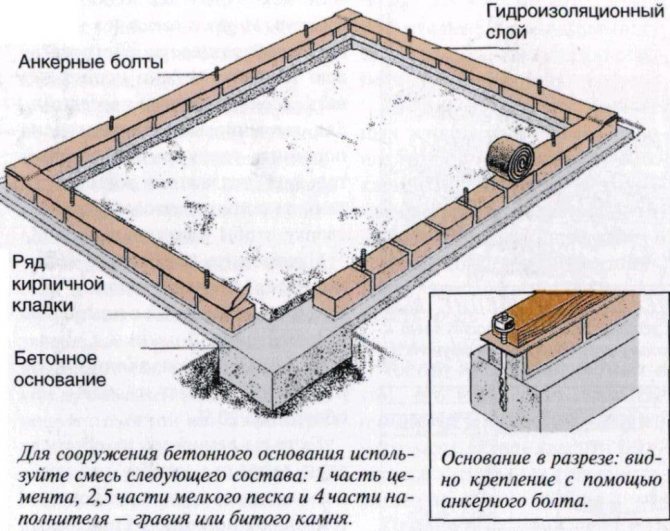

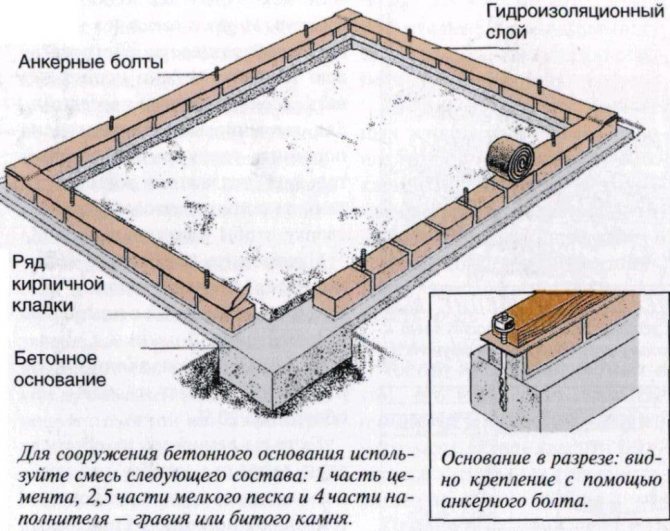

Foundation

The foundation is the basis and the main support for all structures of the future structure. Therefore, it is necessary to carefully approach its bookmark. Initially, you should find out the composition of the soil where the barn will be located. This will allow you to calculate possible problems in the future structure. Most often, the base of the shed is made of concrete, stone, reinforced concrete blocks. However, if the building is completely wooden and small in size, then it is allowed to use a podium lined with beams as a foundation. The recommended height of the base of the building above ground level is 30 cm.

So that the foundation is not damaged during the movement of groundwater, it must be reinforced when laying it.

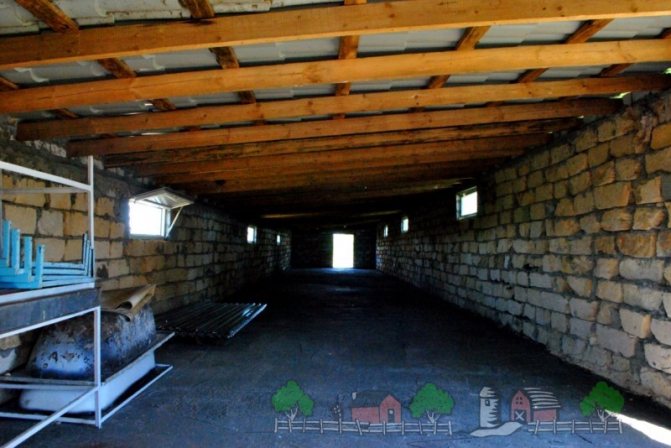

Walls

Walls must be made of materials that can keep the shed warm as much as possible. The most common material for this is brick, cinder blocks, rubble stone. Small farms can make walls from wood, and large ones from reinforced concrete slabs. Inside the building, the walls are upholstered with boards, plastered and whitewashed, depending on the base material. The thickness of the walls directly depends on the thermal conductivity of the material - the more heat conducts from what the wall is made of, the thicker it should be. The height at the walls must be at least 2 meters.

You can learn how to build drinkers for pigs.

The material, height and thickness of the walls should be selected depending on the conditions of the external environment. The best option is the temperature in the pigsty during the winter period not lower than 0 ° C.

Floors

Floors can be made of concrete, but pigs are heat-loving animals. The floors in the pigsty can be wood or concrete. Therefore, it is necessary to take care of its additional insulation. This floor is durable and easy to clean. Wood floors are used along with concrete. It retains heat well, and can also be additionally insulated with clay. A brick floor is an expensive option when making a barn yourself. However, it is ideal in terms of insulation and durability. The best option for a good floor is a concrete base covered with wood.

Wooden planks must be thick, strong, and able to support the weight of the animals.

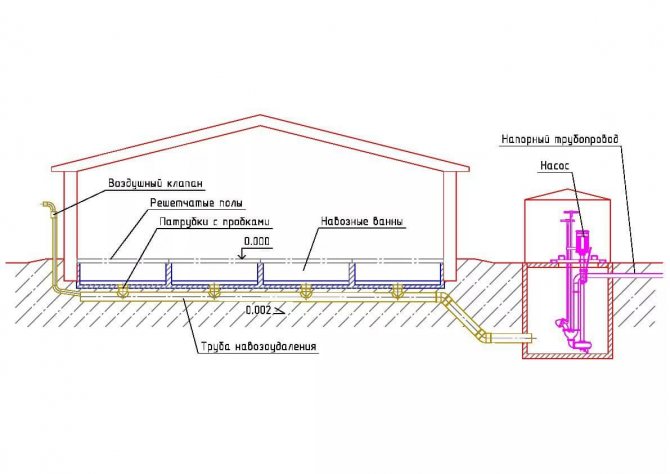

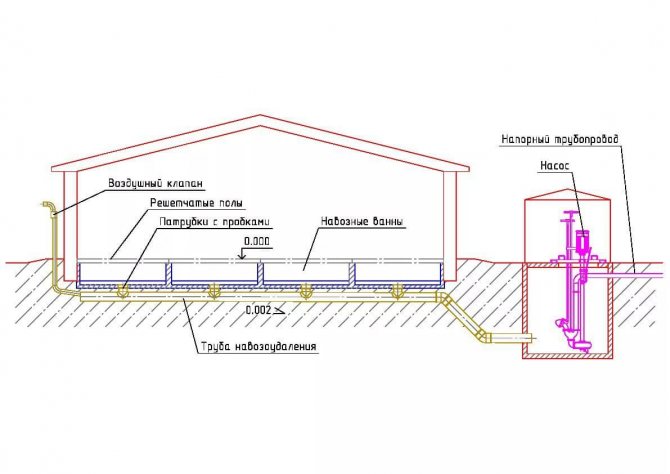

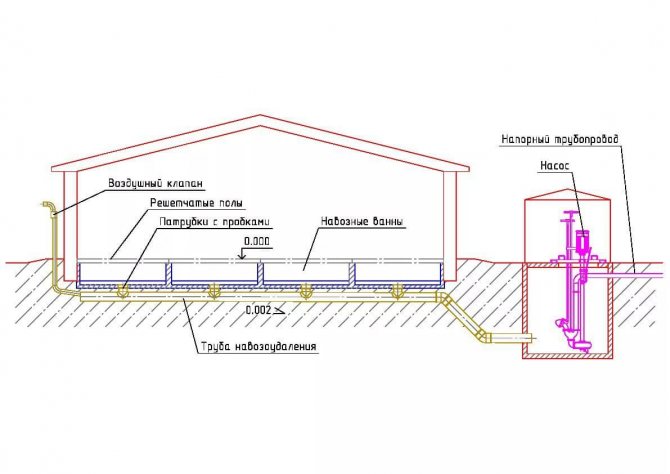

Sewer drawing

Any pigsty must be equipped with a drain. This will make cleaning and caring for the animals easier. It is best to start with a slightly sloped floor so that pig waste can more easily enter the gutter. If possible, a slatted floor can be installed with excreta containers underneath. This method greatly facilitates the process of removing manure, however, it is very costly. To facilitate cleaning of the pigsty, you can run a plumbing into the building.

The barn should be cleaned as often as possible, because pig manure gives off a lot of ammonia fumes.

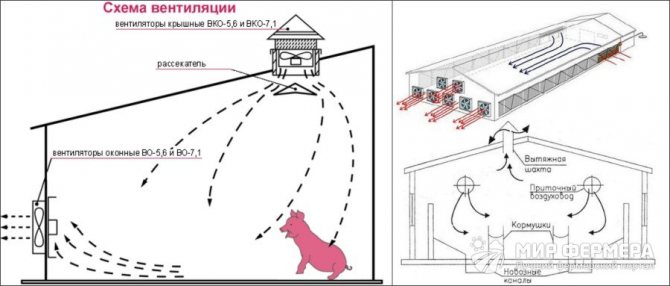

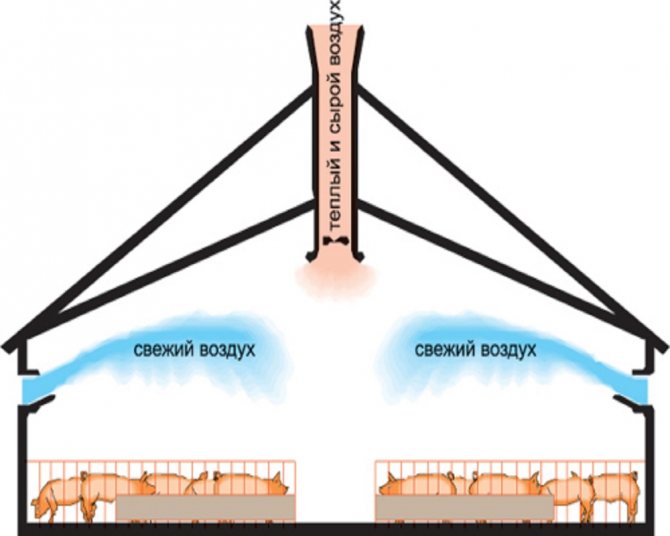

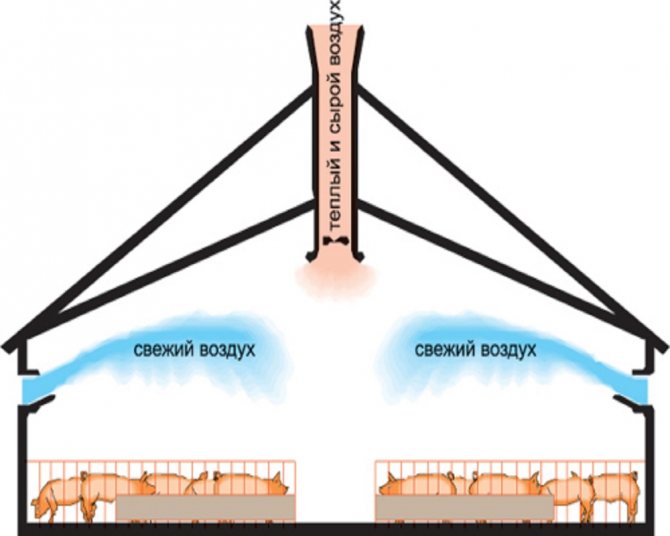

Hood

Any pigsty needs a good ventilation system. Pigs produce a lot of excrement and, as a result, a lot of harmful fumes. Therefore, the shed must be equipped with ventilation. It will allow you to timely replace stale air with clean air. When making a hood, it should be remembered that pigs cannot tolerate drafts. The exhaust system must be installed in such a way that the room maintains an optimal microclimate without harm to animals.

Heating, how to properly insulate

Pigs generate enough heat.Therefore, in general, the pigsty is not supplied with additional heating, but only insulated. If the animals will be kept in the barn for a year, then it is necessary to equip it with a good heating system. To do this, use stove heating or another possible option. The optimum temperature for keeping is 13-22 ° C. In sow pens, the temperature should be within 28 ° C. For this, heating devices are installed there.

Lighting in the pigsty

When kept at home, in a barn, lighting is necessary - natural and artificial. Windows are used for natural light - sunlight enhances biological processes. But with a short daylight hours, this is not enough. Therefore, it is necessary to install additional artificial lighting. Different types of pigs require different lighting for its duration and strength. The ideal option would be a shed with several zones in which the lighting is different in power. Smooth, light-colored walls and ceilings enhance the illumination.

Also read about how to build do-it-yourself pig feeders in this article.

Video

This video tells about the device of a pigsty with maximum automation at home.

The question of building a shed for pigs should be approached responsibly. Every person who is going to raise animals should understand that their health status, growth rate and ability to reproduce directly depend on the conditions in which they are kept. Individuals living in a clean and spacious room usually get sick less often and have a good appetite. That is why we propose to figure out how to build a solid pigsty with your own hands.

Basic requirements for a future pigsty

Even in non-professional conditions, the pig shed must be built correctly, taking into account all the necessary conditions and requirements. General parameters can be represented as follows:

Pigsty project option

- An even place, located far from any residential buildings (at least 15-18 meters). The area for the pigsty should be free from loud sounds (railway lines, highways) and exposure to bright light sources (street lamps or floodlights).

- Lack of nearby water sources (river, lake, pond). Wetlands are considered especially unfavorable. It has been proven that pigs living near swamps get sick on average 2-3 times more often.

- The placement of the pigsty should be in accordance with the prevailing wind directions. This is necessary for choosing the right place for construction, so that an unpleasant smell does not constantly enter residential buildings.

- Absence of significant temperature drops. In cold and temperate climates, you should take care of insulation and ventilation in advance. Low temperature reduces the effect of local and general factors of immunity, which adversely affects resistance to various types of pathogens.

- Providing sufficient space, in accordance with all regulations. Shy individuals gain weight more slowly, and their offspring are more often born with deformities.

- Placement of artificial light sources (fluorescent lamps are perfect).

- Creation of an uninterrupted supply of liquid and timely filling of the feeders with food.

Industrial farms are an example of the correct placement of pigsties.

We draw up a project

Before starting the initial stage of building a barn, it is important to think carefully about everything. First you need to decide on the purpose of breeding pigs on the farm. For example, it may be planned to raise several individuals for meat or keep a small herd for a further increase in its number. The area of the future barn and its internal arrangement will depend on the goals set..

When calculating the area of the building, be sure to pay attention to the following parameters:

- sows and boars are best kept in separate sections, the area of which should be at least 4 m 2;

- animals for slaughter can be raised in a single enclosure, the size of which is calculated by the number of individuals and the area allotted for each of them - from 0.9 m 2 (these are the minimum norms);

- it is not recommended to keep more than 25 pigs in one section.

If the animals will live with you all year round, it makes sense to equip a special paddock near the barn for walking them. It is better to place it along the long wall of the building. The "walking" area should be planned at the rate of 10 m 2 per boar or sow and 1.5 m 2 per head of the fattening herd.

When calculating the required area, it is also necessary to take into account the breed characteristics of the selected animals: size, growth rate, susceptibility to stress, the need for walking on pastures and the specifics of feeding. So, miniature Vietnamese pot-bellied pigs, which are fed mainly with green and juicy feed for 7-8 months before the slaughter weight, on average about 75-80 kg of space in the barn, will require less space than, for example, large white ones capable of gaining more than 200 kg (pigs ) and over 300 kg (boars).

After you have decided on the area of the future structure and walking area, you need to decide where the pigsty will be located. If you follow the sanitary standards (SNiP 30-02-97), then the shed for pigs should be at least 12 m from the house and 4 m from the border of your site. When choosing a place for construction, remember that you will have to water and feed the animals several times a day, as well as clean and remove their waste products. Therefore, it is necessary to decide in advance on the place of the manure heap and make sure that it is convenient to approach the barn.

Technical equipment and ventilation

Animals such as pigs emit colossal amounts of gases and are the source of extremely unpleasant odors. Additionally, the risk of developing infectious and inflammatory diseases increases in a polluted atmosphere. Therefore, ventilation is indispensable.

Air ventilation can be carried out by means of a conventional ventilation pipe or corrugation with an installed fan.

Simple ventilation option

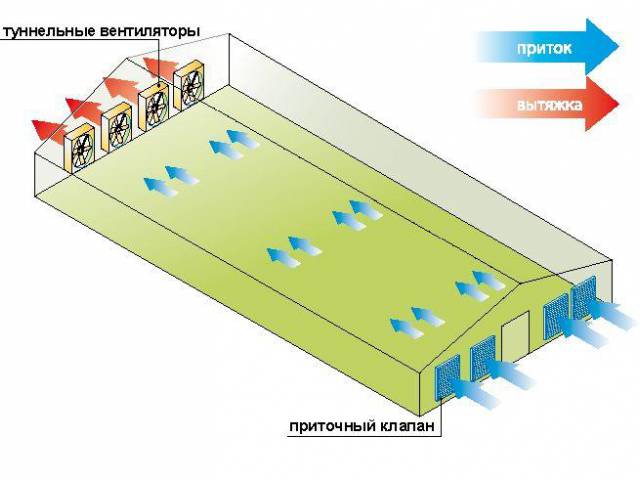

There are industrial ventilation solutions that are tailored to the number of pigs in the barn.

In the summer, the movement of the air currents should be more intense than in the rest of the year. At the same time, drafts quickly lead to diseases and death of the herd. Consequently, the placement of windows and doorways should be with regard to the number of heads and insulated. It is better to make windows double or triple, with sashes. Height - not less than 1.5 meters from the floor level.

Industrial ventilation option

It is imperative to keep indoor humidity between 70 and 75 percent. A humid environment is ideal for the development of inflammatory pathologies from the upper respiratory tract, and too dry quickly leads to an increase in the number of insects and rodents.

Stages of building a pigsty for 2 heads

Each pigsty should contain premises such as:

- sleeping area for animals;

- walking area;

- walk-through vestibules.

Walking area allows pigs to feel full

The floor structure bears all the main load and must be extremely strong. As the characteristics of resistance decrease, materials can be represented as follows:

- concrete;

- prefabricated reinforced concrete blocks;

- artificial stones;

- brick.

Before laying, the foundation is deepened into the ground by 0.5-1 meters.

Important. It is necessary to ensure that the base is not washed by groundwater. If during the digging process they were found, then another place should be preferred.

When erected on clay soil, the foundation deepens another 40-50 centimeters to protect it from freezing. On the surface of the earth, a rim base is constructed, 10-50 centimeters wide.

Erection of the foundation

After complete laying and drying, the surface is covered with roofing material.

Walls are always erected from durable, but lightweight materials. The ideal for their construction is wood concrete, but the percentage of its use in practice is extremely small. The product is made from a mixture of sawdust, ordinary cement and water. A number of antifungal supplements are also added.

An example of a wall made of wood concrete

An additional advantage of wood concrete is its thermal insulation performance: it retains heat well inside the room, does not collapse, thereby not contributing to the appearance of drafts.

Important. Another material for the construction of walls is brick, but it is extremely expensive and requires additional insulation.

The most common frame option is solid timber or sleepers. Such walls are warm, light, and keep heat well. For additional protection from the cold outside air currents, it is necessary to heal the crevices.

Pigsty walls made of timber

Ceiling and roof construction

Ceilings are usually made of wood or reinforced concrete. Top covered with a layer of sand with sawdust or chaff. The additional construction of the attic allows you to store food, water, bedding materials there, and the air layer is a means of additional thermal insulation. In any case, the height of the ceiling (which should be flat) should not exceed 2.4 meters, with an insulated roof - no more than 1.8 meters.

The roof of the pigsty must be with a slope (1 or 2 - not so important)

Floor

Floors must be durable and easy to clean. A simple option is to make a self-leveling concrete floor.

There are the following types of floors that have earned high popularity:

- Concrete. After pouring, shields are applied (it is better to use removable ones). On top they are spread with straw or sawdust, thereby organizing a sleeping place for the animal. Covers should be grooved and sloped to remove waste products. During general cleaning, the boards are taken out, washed and dried. All waste underneath is removed. The concrete shelf must be disinfected every 7 days.

- Slatted or slatted floor. It is mounted on support beams made of bricks or other sturdy building materials. Sewerage is being built under the floor. When using wooden coatings, they should be pre-treated with water-repellent compounds.

- Solid wood floor on a concrete base. This option is cheaper than competitors, but is not recommended.

With lattice coverings, cleaning is done with a tap simply - rinsing under a massive stream of water.

Slatted floor covering in a pigsty

Heating

Steam heating or a gas boiler can be used to raise the air temperature inside the pigsty in winter. Furnace heat systems should not be used due to the high gas content.

Diagram of a simple heating system

Floor is an important element of the building

A pigsty floor requires special attention if you want it to be not only warm, but also durable. You can make it:

Concrete floors they are practical and reliable, they are very convenient to clean. However, if you intend to keep pigs all year round, then such a foundation is not the best choice. The fact is that concrete tends to cool quickly, therefore, animals will freeze and gain weight much more slowly.

Brick floor is considered the "golden mean" when it comes to thermal insulation and durability. That is why this option is often used by farmers.But even here it has its drawbacks: it is quite difficult and costly from a financial point of view to lay out a brick floor on your own.

Wooden floor - the most popular and affordable, usually made of even thick boards. The pigs will be quite comfortable on it, even when the temperature outside is freezing. However, the durability of such a coating is poor.

There are also combined flooring options that allow you to create a warm and at the same time durable surface. Let's consider one of them.

First you need to knock down a dense wooden board and drill holes with a diameter of 10 mm in it. Then you can proceed to the implementation of the second stage of work, the essence of which boils down to pouring concrete with a surface with a slope of 5 degrees towards one of the walls. A concrete gutter is made under this wall, in turn slightly inclined towards a special container ("bath") for waste. Next, the shield, which was discussed a little higher, is tightly laid on the screed. Thus, a warm floor is obtained that will last longer than a conventional wood flooring. Pig urine will flow through the drilled holes to the gutter due to the subtle slope of the floor. When the wooden frame becomes unusable, it can be replaced with a new one, which is much easier than replacing the floors again.

Read also: Zhk altyn yar ufa

The owner of the courtyard should understand that such a floor should be done only if the pig room is supposed to be heated in the cold season.... In an unheated pigsty, animal waste in frost will form ice on the surface of the boards and under them, which will negatively affect both the sanitary condition and the microclimate of the room.

How to build a pigsty with your own hands, you can see in the following video:

Internal arrangement of the pigsty

As already mentioned, the floor should have a slope, which is directed towards the sewer or ebb canal, built in advance. The ditches are not made in the main aisle through which the animals are fed, but from the side of the pens.

Important. Inside each box, feeders are installed, again, on the side opposite to the drain channel.

The feeder is fixed to the floor. For two heads, one piece will be enough. It is better to make the bottom rounded, for the convenience of cleaning, which is carried out once a day.

An example of a trough without jumpers. The pig quickly contaminates itself and reduces the purity of food

Bridges are made on top of the feeder for additional hygiene so that pigs do not sink with their heads or dirty hooves. You can read more about feeding pigs in our article.

Pig Feeder Requirements

Uninterrupted water supply is carried out using drinking bowls. They are important segments of a pigsty, as water is an ideal breeding ground for any infectious agent.

There are 3 main types of drinkers used:

- nipple;

- cup;

- vacuum.

Important. Depending on the weight of the animals in the pigsty, an individual height for the placement of aquifers is selected.

Table 2. The height of the placement of aquifers in the pigsty

| Animal weight | Up to 20 kg | 20 to 50 kg | 50 to 100 kg | Over 100 kg |

| Drinking cup height | 8 cm | 15 cm | 22-26 cm | 25-35 cm |

| Height of nipple drinker | 15 cm | 40 cm | 55 cm | 65-75 cm |